Drawing pin one-time forming production equipment and drawing pin production process

A kind of production equipment and push pin technology, which is applied in the field of push pin one-time molding production equipment and push pin production technology, can solve the problems of weak connection between the nail cap and the nail pin, and the detachment of the nail cap and the nail pin, so as to achieve high material utilization rate, The effect of fewer machines and less difficulty in maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

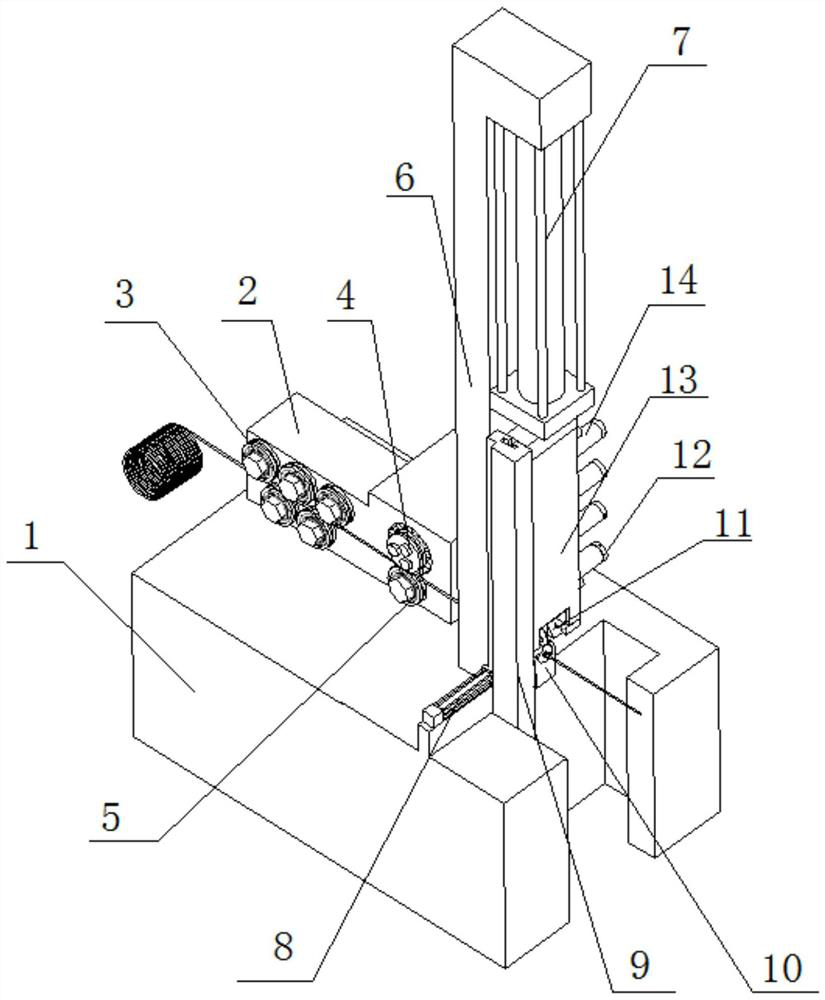

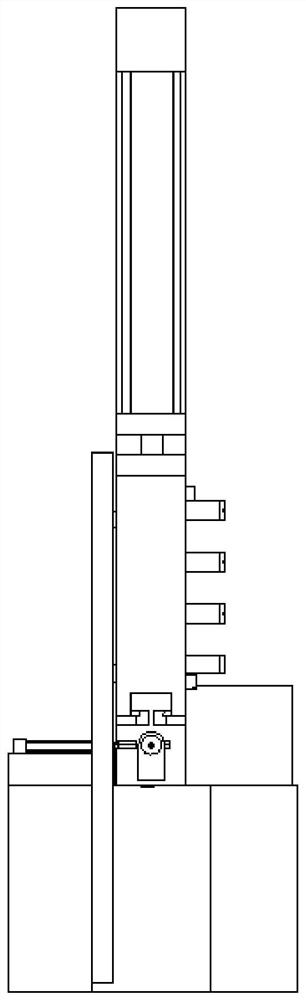

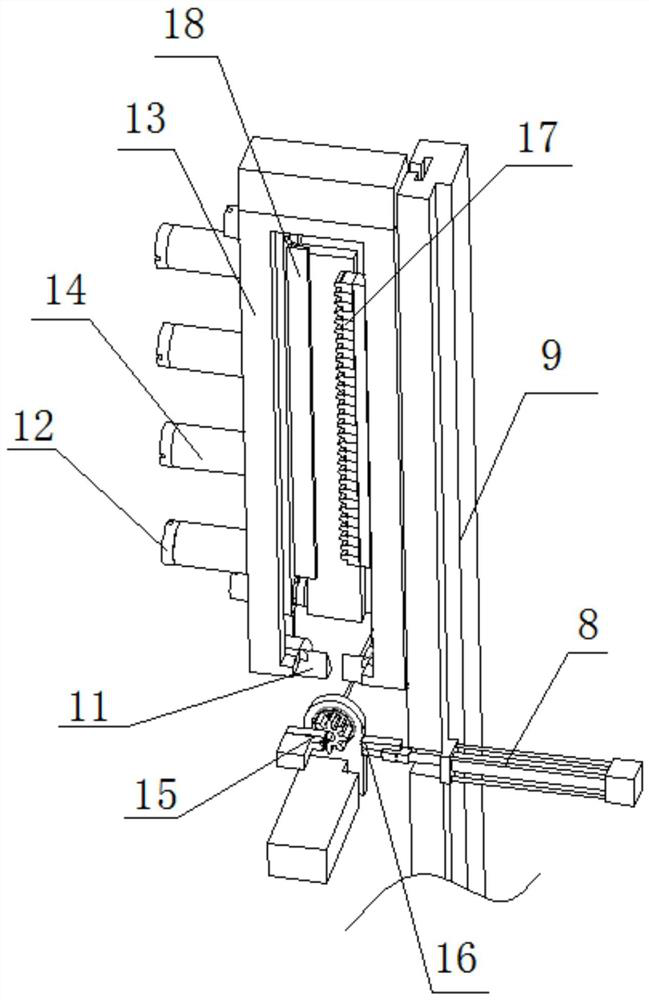

[0030] refer to Figure 1 to Figure 7 The embodiment of the pushpin one-time forming production equipment of the present invention will be further described.

[0031] A push pin one-time forming production equipment, comprising a workbench 1, a steel wire straightening mechanism and a column 6 are provided on the workbench 1, a through hole for the steel wire to pass is provided on the column 6, and a through hole is provided on the column 6 There is a fixed seat 10, and the fixed seat 10 is rotatably connected with a bearing 23 consistent with the axis of the through hole. One end of the bearing 23 is provided with a gear 27, and the other end is provided with a steel wire guide post 24. On the described steel wire guide post 24 A vertically downward slit 25 is provided, and a first cutting block 16 and a second cutting block 15 for cutting steel wires are provided on both sides of the fixed seat 10, and the first cutting block 16 is connected with a second Cylinder 8, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com