A 5g-based hazardous chemical storage tank detection robot

A technology for robots and hazardous chemicals, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of rising temperature of transported materials, inadequate monitoring, and inadequate detection of storage tank status, so as to improve detection efficiency and high efficiency. safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

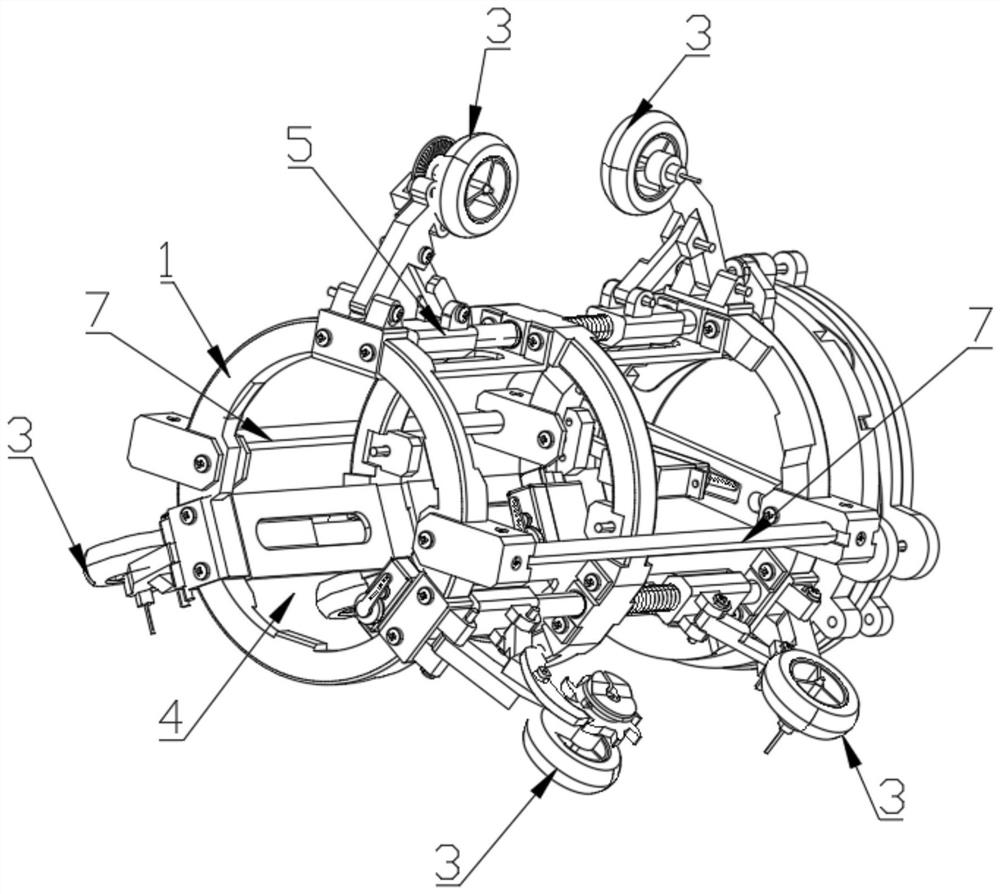

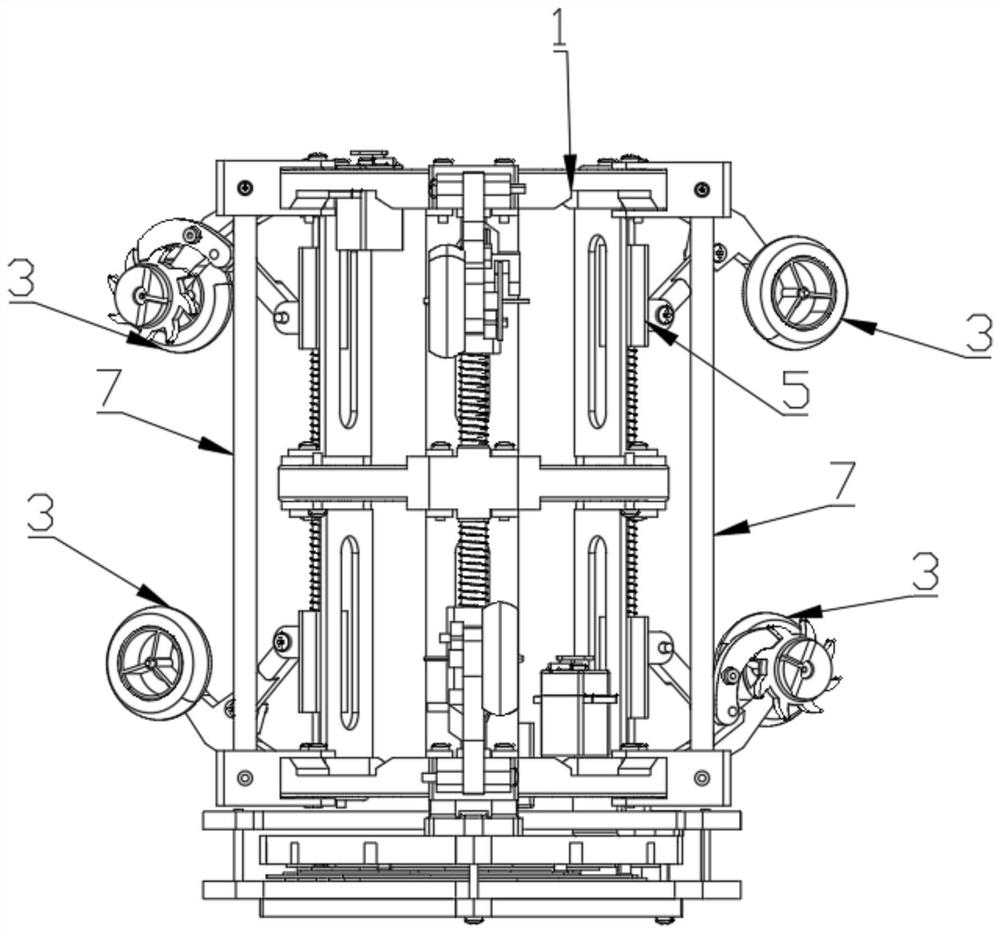

[0030]Embodiment 1: A 5G-based dangerous chemical storage tank detection robot, including a model generation device, a detection device, a protection device, a transmission device and a controller 2, the model generation model is configured to establish a storage model, and based on The storage rules of the storage material are stored, and a list for detection is generated; the detection device is configured to detect the model parameters set by the model generation device; the protection device is configured to detect the dangerous situation of the storage tank 8 Processing; the model generation device, the detection device, and the protection device are respectively connected to the controller 2; the model generation device includes: a setting mechanism, a conditioning mechanism, an energy distribution diagram generation module and an adjustment mechanism , the setting mechanism is configured to define a set of parameters of the storage tank 8, and generate an energy profile ...

Embodiment 2

[0031] Embodiment 2: This embodiment should be understood as at least including all the features of any one of the preceding embodiments, and further improvements are made on the basis of it. Specifically, a 5G-based hazardous chemical storage tank detection robot is provided, including a model Generating device, detecting device, protective device, transmission device and controller 2, described model generating model is configured to establish to storage model, and store based on the storage rule of storage material, and generate and be used for detecting list; Said detecting device It is configured to detect the model parameters set by the model generation device; the protection device is configured to handle the dangerous situation of the storage tank 8; the model generation device, the detection device, and the protection device are respectively It is controlled and connected with the controller 2; specifically, in this embodiment, the storage tank 8 is used to store hazar...

Embodiment 3

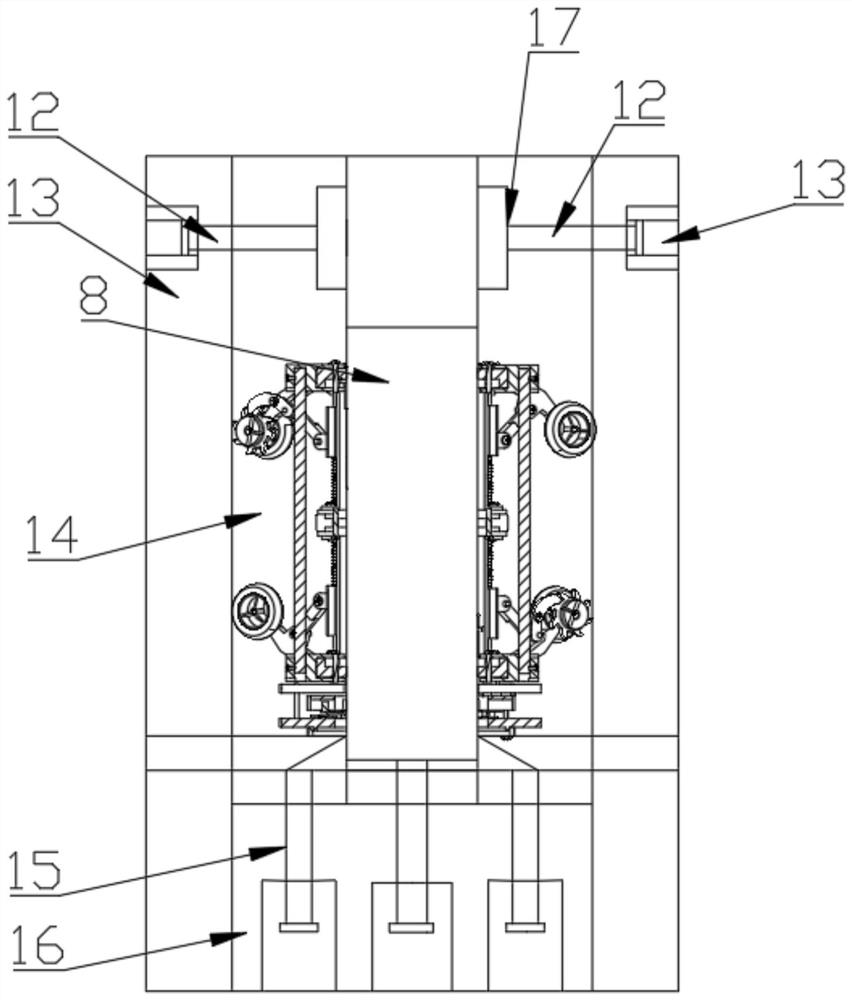

[0039] Embodiment 3: This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and further improvements are made on the basis of it. Specifically, a deviation correction device 16 is provided, and the deviation correction device 16 is arranged on the The bottom of the storage tank 8 is disassembled and connected with the storage tank 8 to ensure that the storage tank 8 will not be impacted during transportation and will not affect the hazardous chemicals stored in the storage tank 8; the correction The device 16 includes a base plate, a fixed plate, several telescopic rods 15 and an induction mechanism, each of the telescopic rods 15 is arranged on one side of the fixed plate, and the induction mechanism is arranged on the fixed plate and detects the fixed The offset angle of the plate, in this embodiment, the bottom plate and the fixed plate are arranged in parallel and coaxially, and each telescopic rod 15 is set betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com