A kind of reservoir wettability improving agent and preparation method thereof

A technology of improving agent and solvent, which is applied in the field of oil reservoir wettability improving agent and its preparation, which can solve the problems of complicated on-site liquid configuration and low oil change ratio, and achieve the effect of enhancing oil recovery and improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

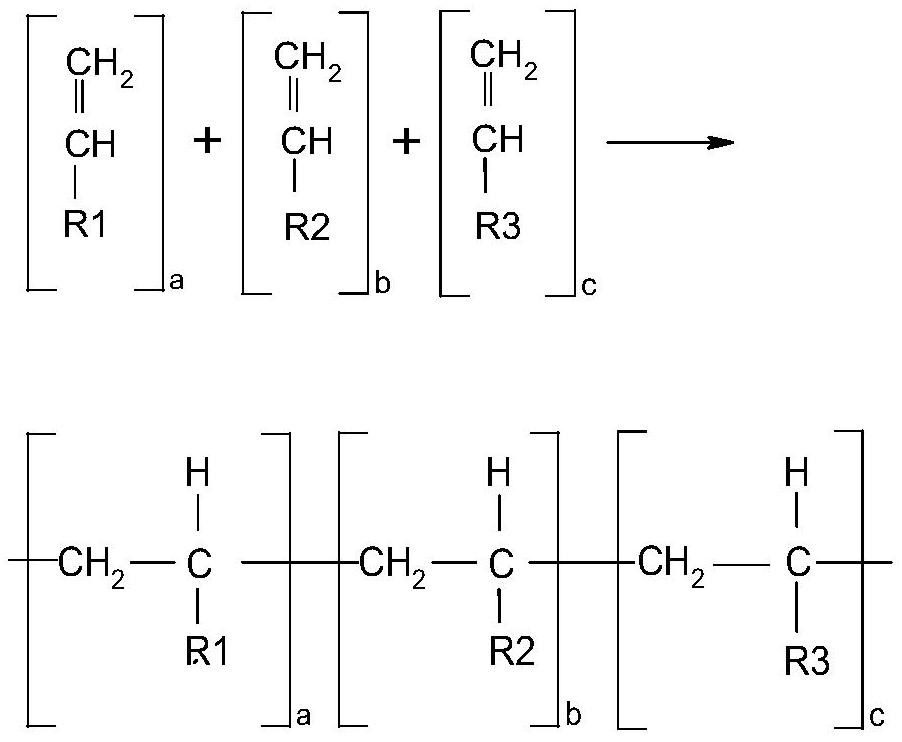

Method used

Image

Examples

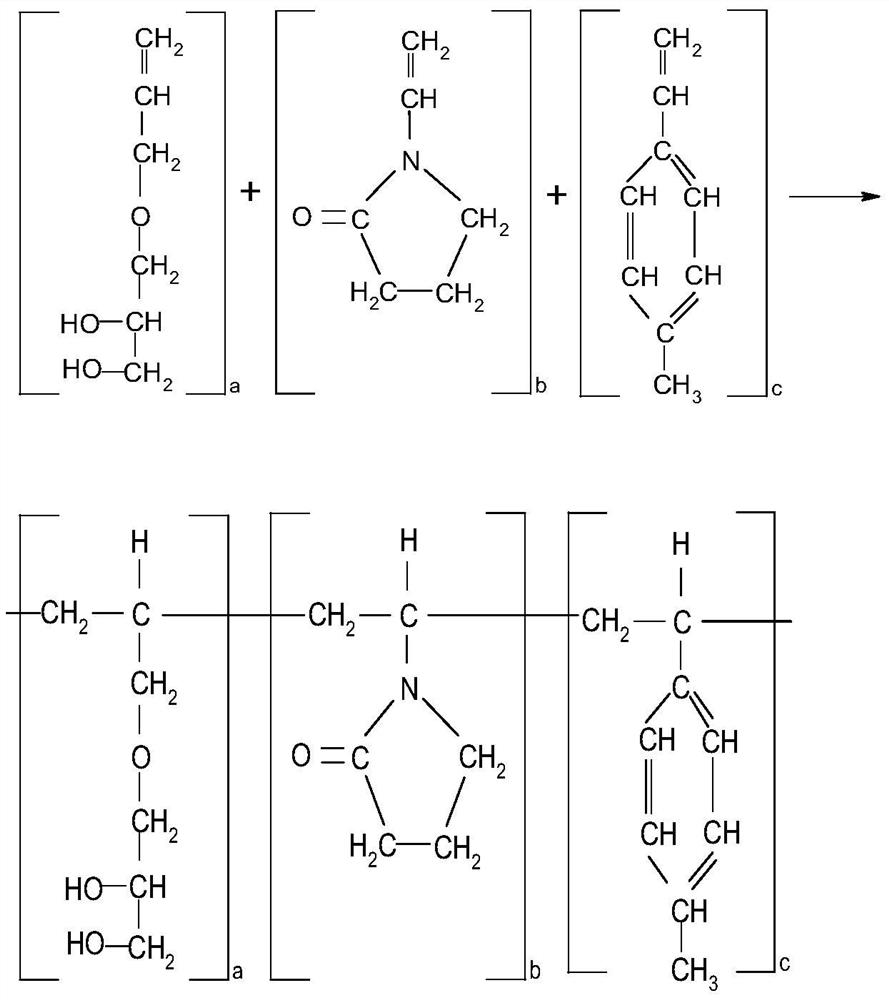

Embodiment 1

[0030]In a four-mouth flask equipped with a stirrer, constant pressure drip funnel, the thermometer, and condenser was injected into the nitrogen displacement air, and an appropriate amount of reactants glycerol allyl ether (AG), N-vinylpyrrolidone (NPV), p-methylstyrene (PMS), an appropriate amount of reducing agent sodium benzene sulfonate was added, and an appropriate amount of phase transfer agent propylene glycol phenyl ether was added, wherein the molar ratio of the reactants, reducing agents, and phase transfer agents was n (glyceryl allyl ether): n (N- vinylpyrrolidone): n (p-methylstyrene): n (sodium benzenesulfonate) : n (propylene glycol phenyl ether) = 6:1:1:0.08:2. Solvent deionized water to p-methylstyrene molar ratio of n (deionized water): n (p-methylstyrene) = 87:1, add 70% molar parts of deionized water to the four flasks, stirred at 250 rpm for 30 minutes. Initiator ammonium persulfate to N-vinylpyrrolidone molar ratio of n (ammonium persulfate): n (N-vinylpyrro...

Embodiment 2

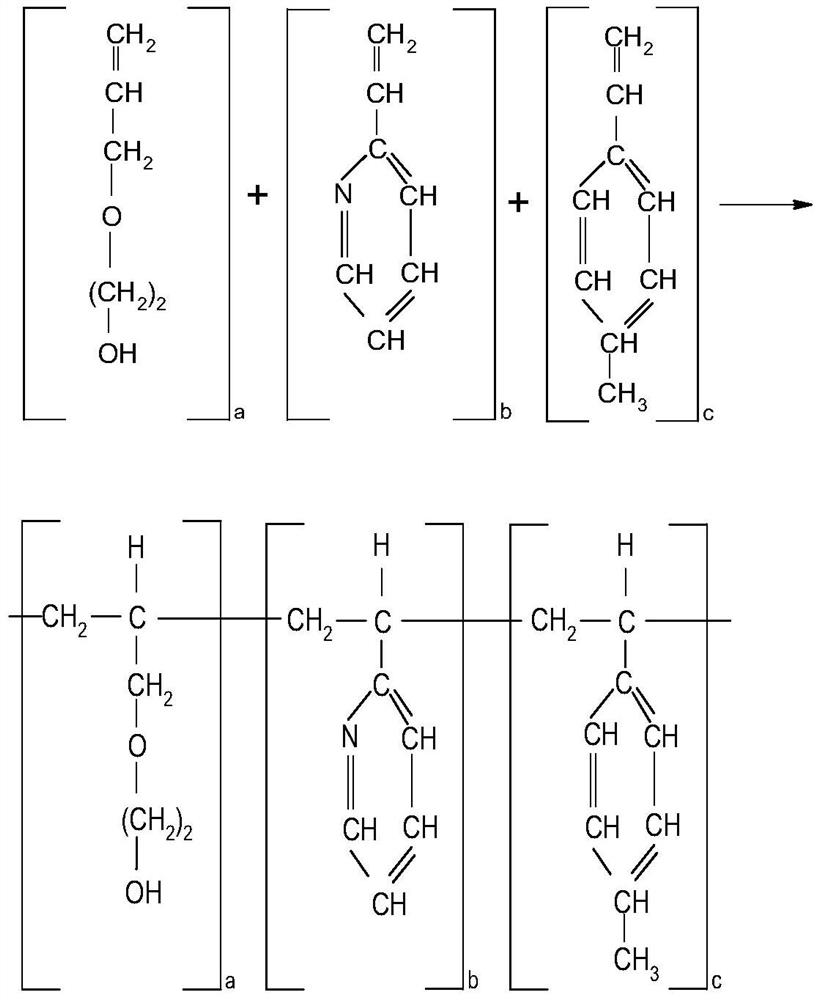

[0035]Nitrogen displacement air was introduced in a four-mouth flask equipped with a stirrer, a constant pressure drip funnel, a thermometer, and a condenser, and an appropriate amount of reactants ethylene glycol monoallyl ether (AOE), 2-vinylpyridine (2VP), p-methylstyrene (PMS), an appropriate amount of reducing agent sodium benzene sulfonate was added, and an appropriate amount of phase transfer agent propylene glycol phenyl ether was added, wherein the molar ratio of the reactants, reducing agents, and phase transfer agents was n (ethylene glycol monoallyl ether): n (2-vinylpyridine): n (p-methylstyrene): n (sodium benzenesulfonate) : n (propylene glycol phenyl ether) = 18:2:1:0.2:6. Solvent deionized water to p-methylstyrene molar ratio of n (deionized water): n (p-methylstyrene) = 114:1, add 70% molar parts deionized water to the four-mouth flask, stirred at 250 rpm for 30 minutes. The molar ratio of the initiator ammonium persulfate to p-methylstyrene is n (ammonium persul...

Embodiment 3

[0040]In a four-mouth flask equipped with agitator, constant pressure drip funnel, thermometer, condenser through the nitrogen displacement air, add the appropriate amount of reactants allyl polyoxyethylene methyl ether (HPEG) (n = 10), N- vinyl caprolactam (NVC), styrene (St), add an appropriate amount of reducing agent sodium benzene sulfonate, add an appropriate amount of phase transfer agent propylene glycol phenyl ether, wherein the molar ratio of reactants, reducing agents, phase transfer agents is n (allyl polyoxyethylene methyl ether (n = 10)): n (N- vinyl caprolactam) : n (styrene): n (sodium benzenesulfonate): n (propylene glycol phenyl ether) = 4: 1: 1: 0.06: 2. Solvent deionized water to styrene molar ratio of n (deionized water): n (styrene) = 159:1, add 70% molar parts deionized water to the four flasks, stirred at 250 rpm for 30 minutes. The molar ratio of the initiator ammonium persulfate to styrene is n (ammonium persulfate): n (styrene) = 0.06:1, the ammonium per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com