Resin composition, preg, laminated board, preg production method, laminated board production method and use of laminated board

A technology of resin composition and prepreg, which is applied in the field of communication materials, can solve the problems of reduced electrical insulation performance, poor thermal conductivity, and heat dissipation performance that cannot meet the heat dissipation requirements of high-power devices, so as to achieve low dielectric loss and meet the needs of high-frequency communication. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

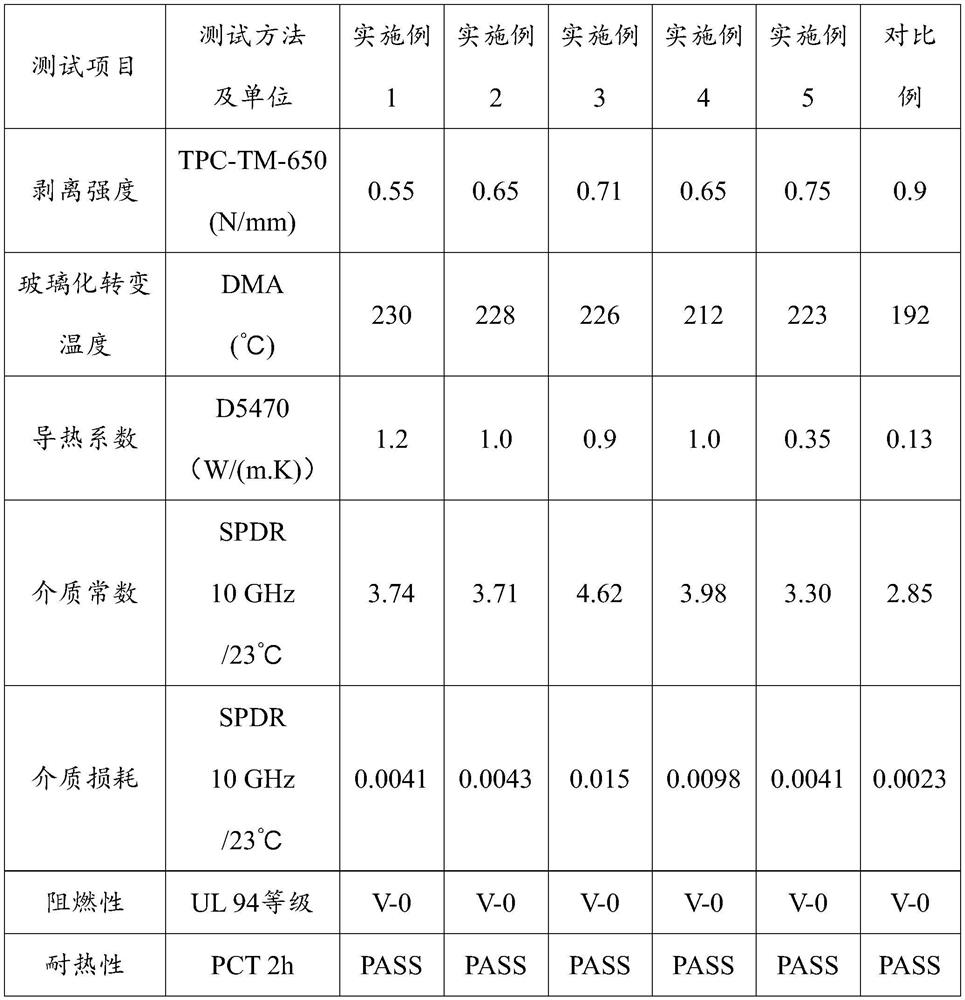

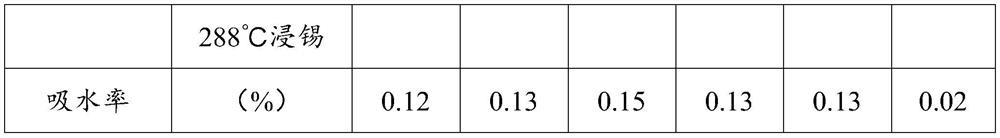

Examples

preparation example Construction

[0052] The preparation method of above-mentioned prepreg comprises the following processes:

[0053] The above resin composition is dissolved in a solvent to form a glue solution, and then the reinforcing material is immersed in the glue solution, and the impregnated reinforcing material is heated to make it semi-cured to form a prepreg.

[0054] The invention also discloses a laminated board, which comprises the above-mentioned prepreg and conductive metal sheets stacked on one or both sides of the prepreg. The prepreg can be one, or two or more prepregs stacked in sequence.

[0055] Preferably, the conductive metal sheet is copper foil.

[0056] The preparation method of above-mentioned laminated board comprises the following processes:

[0057] One or both sides of the above-mentioned prepreg are covered with a conductive metal sheet, and then laminated to form a laminated board. The prepreg can be a prepreg, or two or more laminated boards stacked in sequence.

[0058]...

Embodiment 1

[0061] The resin composition comprises the following components in parts by weight:

[0062] 12 parts of methacrylic polyphenylene ether resin (trade name SA9000), 10 parts of butadiene-styrene copolymer resin, 2 parts of polybutadiene resin, styrene-butadiene-styrene triblock copolymer 1 part (SBS resin), 13 parts of boron nitride (BN), 8 parts of modified fused silica, 3.5 parts of decabromodiphenyl ether flame retardant, 1.5 parts of vinyltrimethylsiloxane, 1 part of tert-butyl peroxide diisopropylbenzene (BIPB) initiator.

[0063] Prepare the prepreg:

[0064] 1) Weigh each component according to the above parts by weight.

[0065] 2) Put the methacrylic polyphenylene ether resin into the rubber mixing bottle, then add 32 parts of solvent toluene and 17 parts of butanone into the rubber mixing bottle, and stir until the methacrylic polyphenylene ether resin is completely dissolved.

[0066] 3) Add butadiene-styrene copolymer resin, polybutadiene resin and dissolved SBS ...

Embodiment 2

[0074] The only difference between Example 2 and Example 1 is that the resin composition is different, and the preparation methods and parameters of the prepreg and the copper-clad laminate are the same as those of Example 1.

[0075] In this embodiment, the resin composition includes the following components in parts by weight:

[0076] 12 parts of methacrylic polyphenylene ether resin (trade name SA9000), 10 parts of butadiene-styrene copolymer resin, 2 parts of polybutadiene resin, styrene-butadiene-styrene triblock copolymer 1 part (SBS resin), 8 parts of boron nitride (BN), 13 parts of modified fused silica, 3.5 parts of decabromodiphenyl ether flame retardant, 1.5 parts of vinyltrimethylsiloxane, two 1 part of tert-butyl peroxide diisopropylbenzene (BIPB) initiator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com