A kind of iron tetrasulfide electrode material and its preparation method and application

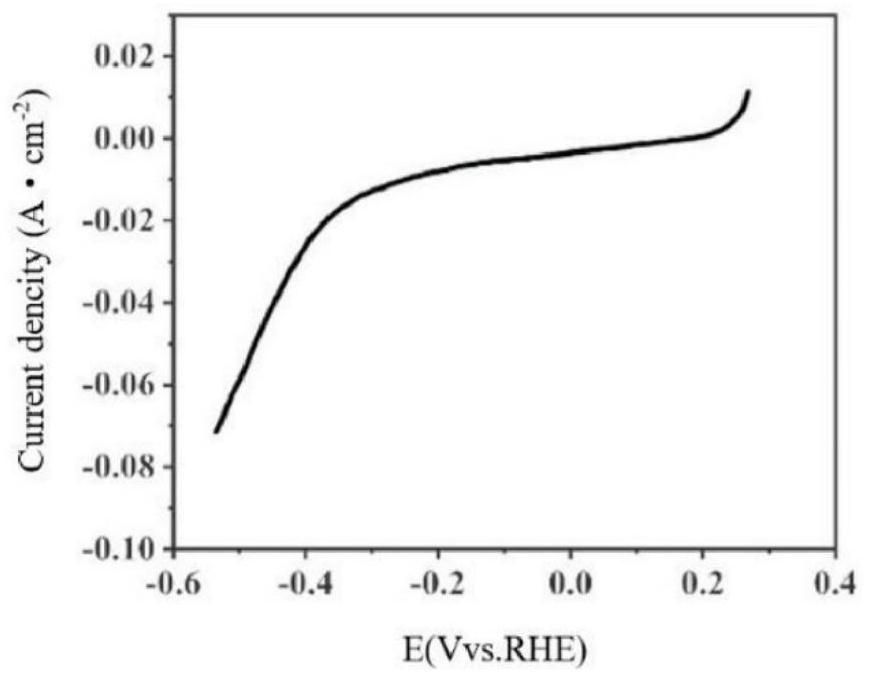

A technology of iron tetrasulfide and electrode material, applied in battery electrodes, biochemical fuel cells, circuits, etc., can solve the problems of cumbersome reaction operation, low product yield, large product particle size, etc., and achieve complete grain development and particle size. The effect of uniform distribution and small and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]A kind of iron tetrasulfide electrode material and preparation method thereof, comprise the steps: first, take by weighing 0.56g ferrous sulfate heptahydrate and pour in the polytetrafluoroethylene liner that 35mL deionized water is housed; Add 1200 μL of ethylenediamine to the solution, seal it, and stir magnetically at a speed of 800r / min for 10 minutes; use a pipette gun to absorb 800 μL of carbon disulfide and add it to the solution (the molar ratio of S:Fe is 1:1, add ethylenediamine per mole of iron source amine 600mL), continue to seal and stir at 800r / min for 10min, seal the stirred liquid in the reaction kettle, transfer it to an oven, and keep it warm at 220°C for 6h. Cool naturally, wash with water, ethanol, and water to remove impurities in turn, collect samples by centrifugation, and freeze-dry for 9 hours.

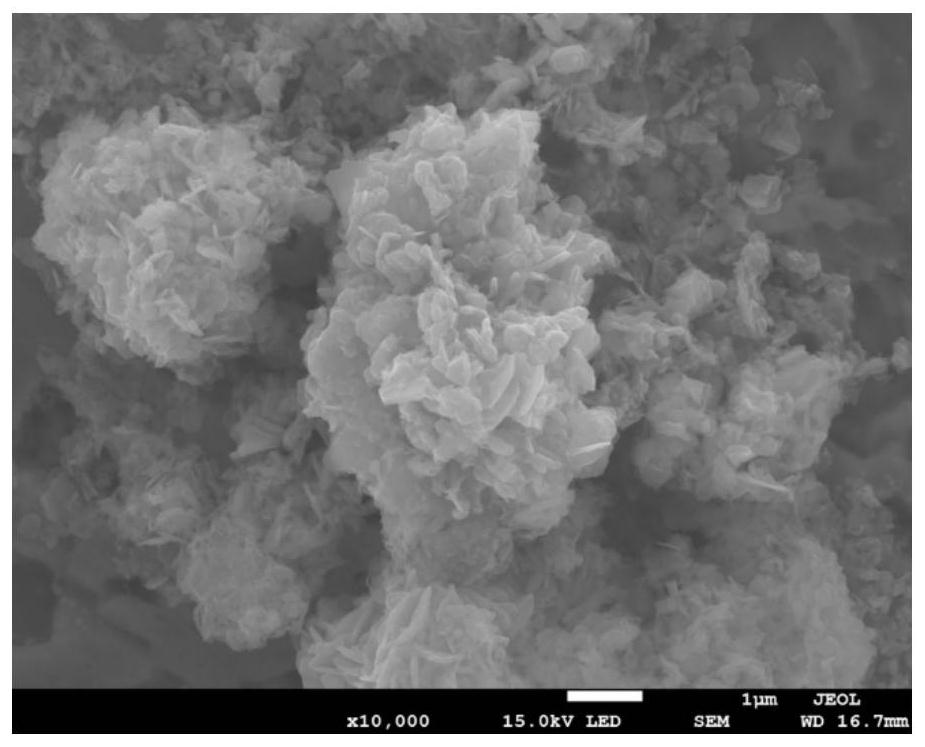

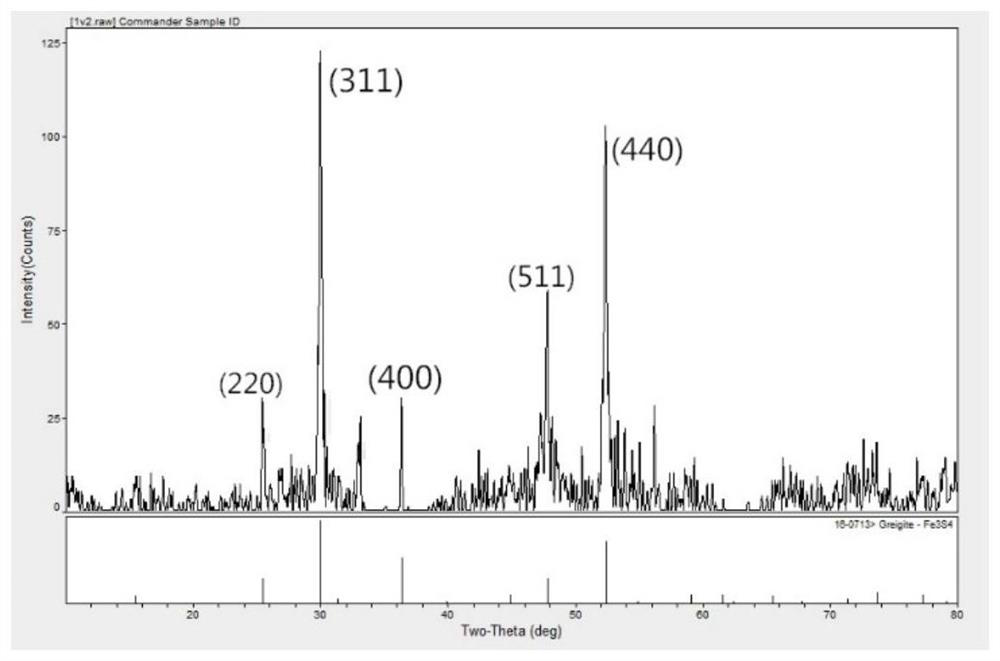

[0037] The scanning electron microscope images of the above examples show a flake structure with a particle size of 50-150 nm, and its composition is o...

Embodiment 2

[0039] A kind of iron tetrasulfide electrode material and preparation method thereof, comprise the steps: first, take by weighing 0.56g ferrous sulfate heptahydrate and pour in the polytetrafluoroethylene liner that 35mL deionized water is housed; Add 800 μL of ethylenediamine to the solution, seal it, and stir magnetically at a speed of 600 r / min for 20 minutes; use a pipette to absorb 800 μL of carbon disulfide and add it to the solution (the molar ratio of S:Fe is 1:1, add ethylenediamine per mole of iron source amine 400mL), continue to seal and stir at a speed of 600r / min for 20min, seal the stirred liquid in the reaction kettle, transfer it to an oven, and keep it warm at 180°C for 12h. Cool naturally, wash with water, ethanol, and water to remove impurities in turn, collect samples by centrifugation, and freeze-dry for 9 hours.

[0040] The scanning electron microscope figure of the iron tetrasulfide prepared by the above examples is as follows figure 1 As shown, the m...

Embodiment 3

[0042] A kind of iron tetrasulfide electrode material and preparation method thereof, comprise the steps: first, take by weighing 0.56g ferrous sulfate heptahydrate and pour in the polytetrafluoroethylene liner that 35mL deionized water is housed; Add 800 μL of ethylenediamine to the solution, seal it, and stir magnetically at a speed of 800 r / min for 20 minutes; use a pipette to absorb 1000 μL of carbon disulfide and add it to the solution (the molar ratio of S:Fe is 5:4, add ethylenediamine per mole of iron source 400mL), continue to seal and stir at a speed of 800r / min for 20min, seal the stirred liquid in the reaction kettle, transfer it to an oven, and keep it warm at 180°C for 9h. Cool naturally, wash with water, ethanol, and water to remove impurities in turn, collect samples by centrifugation, and freeze-dry for 9 hours.

[0043] The scanning electron microscope images of the above examples show a flake structure with a particle size of 100-200 nm, and its composition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com