Integrated supporting roller device

A support roller, integrated technology, applied in the direction of support structure installation, data centers, servers, etc., can solve problems such as troublesome stability, limited support strength, electrostatic floor damage, etc., to avoid excessive pressure, easy to fix, Easy to move effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

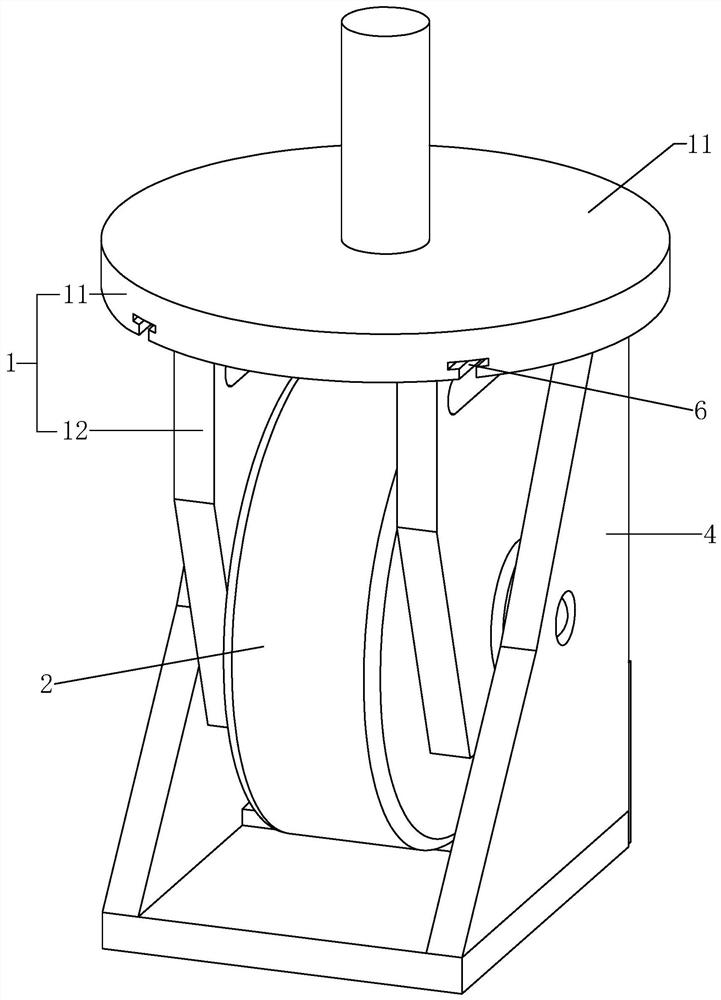

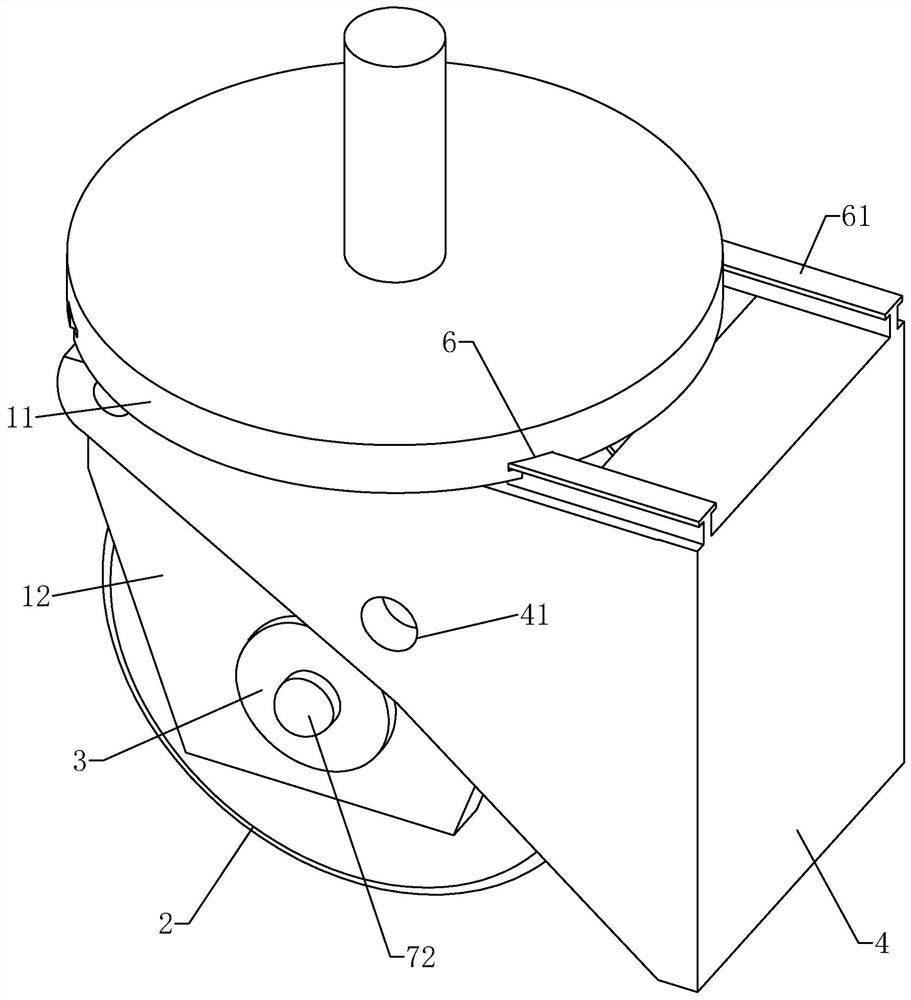

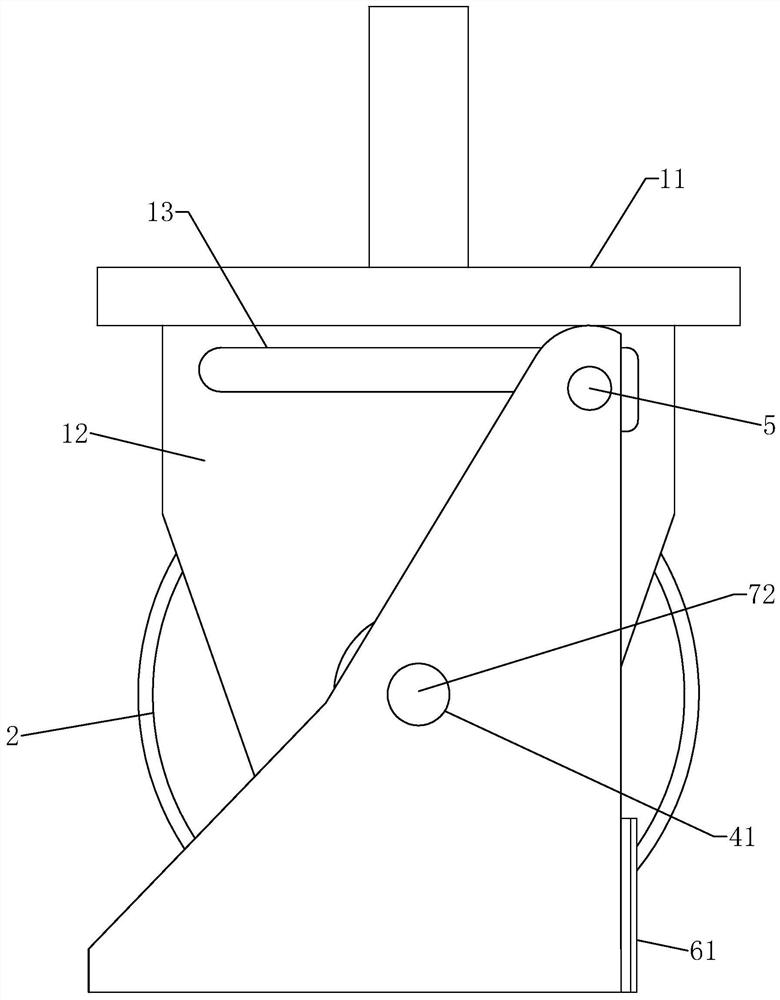

[0019] Example: Reference Figure 1-4 , an integrated supporting roller device, comprising: a bracket 1, a roller 2 and a variable fixed support part, wherein the bracket 1 is an integrally formed structure. The top of the support 1 is a rotating shaft, and below the rotating shaft is a fixedly connected disc 11, and the left and right side plates 12 are symmetrically and fixedly connected to the bottom of the disc 11. In particular, the left and right side plates 12 on the support 1 are provided with circular openings. The hole, the diameter of the through hole is consistent with the diameter of the through hole in the middle of the roller 2 and the diameter of the pin shaft 3, and the roller 2 is rotatably installed between the two side plates 12 through the pin shaft 3.

[0020] refer to Figure 1-4 , the two side plates 12 are symmetrically opened with horizontal sliding grooves 13 close to the disc 11, and the openings at the tails of the sliding grooves 13 become larger...

Embodiment 2

[0024] Embodiment 2, refer to image 3 and Figure 5 , an integrated support roller device, the difference from Embodiment 1 is that there is more structure for locking the U-shaped fixed support plate 4, when the U-shaped fixed support plate 4 enters the support state, the U-shaped fixed support is further improved Plate 4 Stability.

[0025] refer to image 3 and Figure 5 In the pin shaft 3, a mounting hole through the pin shaft 3 is provided along the axial direction of the pin shaft 3, a spring 71 is provided in the mounting hole, a plunger 72 is fixedly provided at both ends of the spring 71, and a U-shaped fixed support plate 4 is provided. There is a limiting hole 41 that cooperates with the plunger 72 . When the U-shaped fixed support plate 4 is in the supporting state, the limit hole 41 is coaxial with the plunger 72, and the plunger 72 is automatically inserted in the limit hole 41 under the action of the spring 71, so that the U-shaped fixed support plate is li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com