Medical mask production equipment and medical mask quality rapid detection method thereof

A technology for production equipment and masks, which is applied in the field of medical mask production equipment and the rapid quality inspection of medical masks, can solve the problems of medical masks losing their ability to prevent epidemics and damage to medical masks, and achieve significant social and economic benefits, convenient operation, Reduce the effect of processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

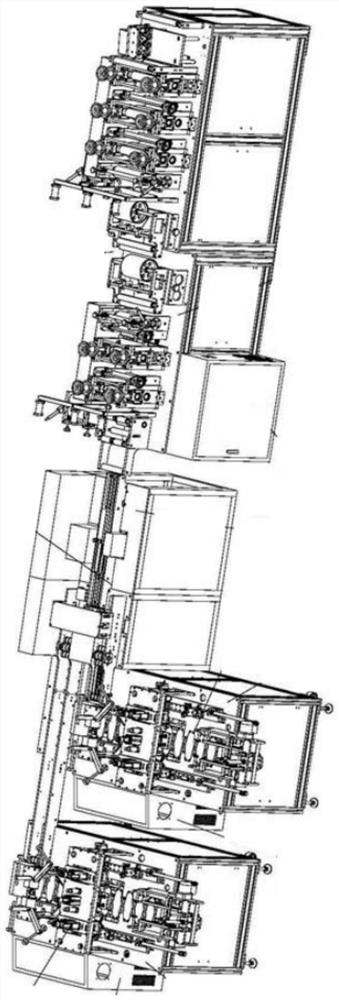

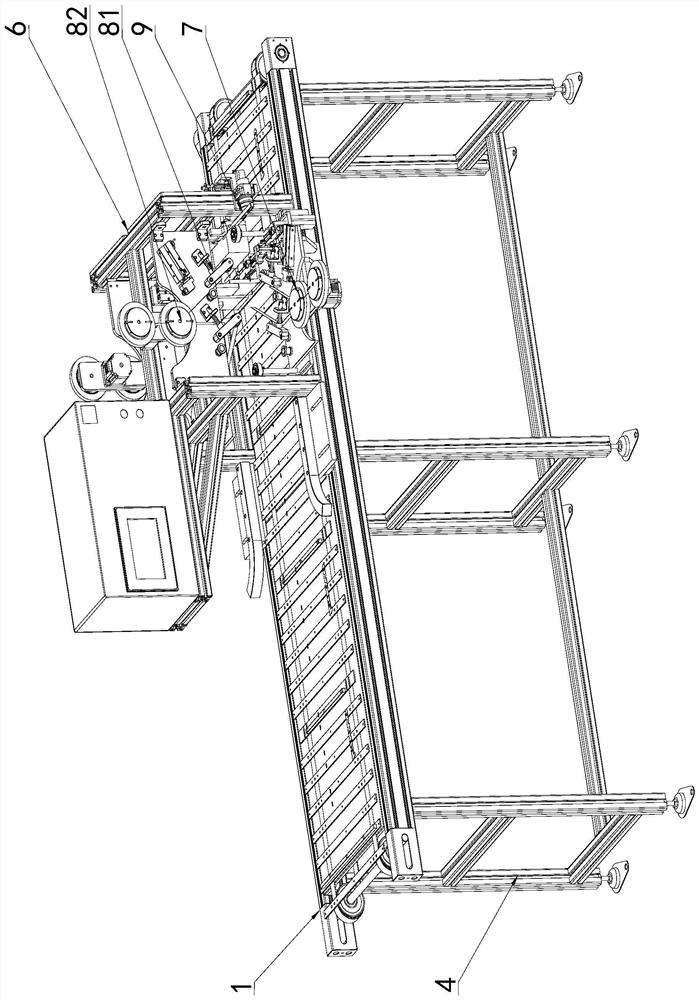

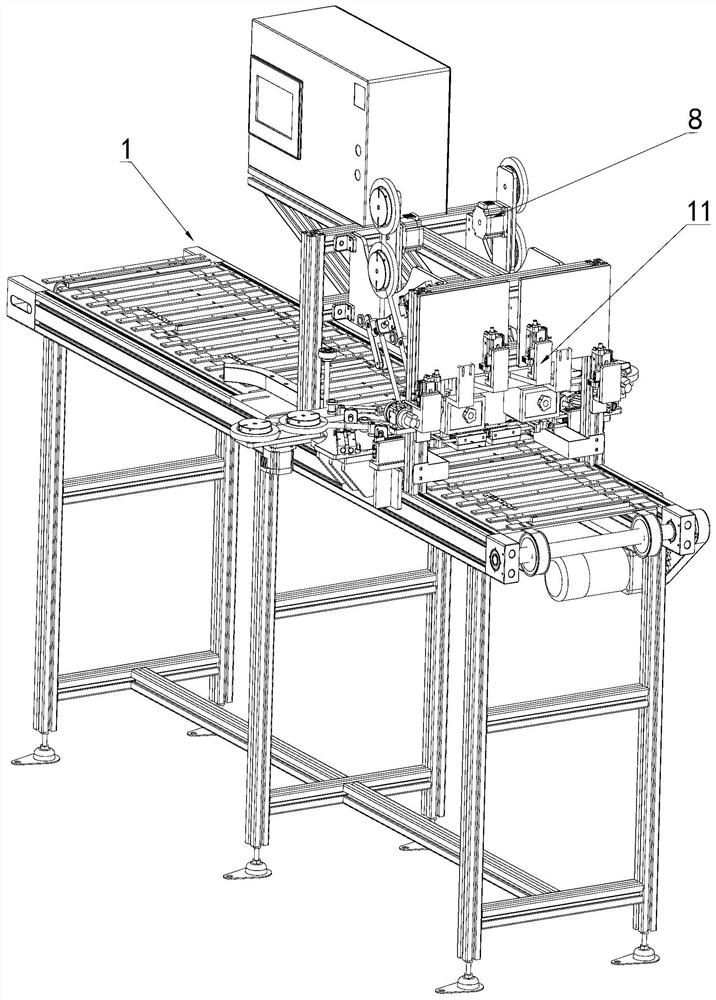

[0033] Such as Figure 1-7 A kind of medical face mask production equipment shown, it comprises frame and the conveying device that is arranged on described frame; Synthesizing module, sewing module for sewing nose bridge strips, laminating module for folding several fabric layers, edgebanding module for sealing the edges of multilayer nonwovens, cutting module for slicing, fixing hanging The heat-pressing fixing module of the ear rope, the detection module used to detect the product medical mask and the killing module used to sterilize the finished medical mask; the detection module includes a physical detection unit, a flexible detection unit and a display unit; the The physical detection unit is connected in communication with the display unit; the physical detection unit includes a camera and a processor; the processor includes a preprocessing module for denoising the grayscale image of the medical finished mask, and a preprocessing module for the medical finished mask A ...

Embodiment 2

[0048] The second embodiment is a further description of the above embodiments. It should be understood that this embodiment includes all the aforementioned technical features and is further specifically described as:

[0049] Such as Figure 1-7 A kind of medical face mask production equipment shown, it comprises frame and the conveying device that is arranged on described frame; Synthesizing module, sewing module for sewing nose bridge strips, laminating module for folding several fabric layers, edgebanding module for sealing the edges of multilayer nonwovens, cutting module for slicing, fixing hanging The heat-pressing fixing module of the ear rope, the detection module used to detect the product medical mask and the killing module used to sterilize the finished medical mask; the detection module includes a physical detection unit, a flexible detection unit and a display unit; the The physical detection unit is connected in communication with the display unit; the physical...

Embodiment 3

[0064] The third embodiment is a further description of the above embodiments. It should be understood that this embodiment includes all the aforementioned technical features and is further specifically described as:

[0065] The quality rapid detection method of a kind of medical mask in this embodiment 3 can not only be applied to the detection of the medical mask in production, also can be used for the detection that consumers usually use to identify whether the mask is qualified. This detection method can detect whether the medical mask is qualified within a few seconds, and the success rate is extremely high. Therefore, the detection method is accurate, fast, convenient and practical, and therefore easy to popularize.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com