Combined type end plate and prefabricated pile

A combined and prefabricated pile technology, which is applied in sheet pile walls, buildings, and foundation structure engineering, can solve the problems of loss of concrete precompression stress, small end face protection of square piles, and weak connection, etc., and achieve high connection strength , to ensure the effect of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

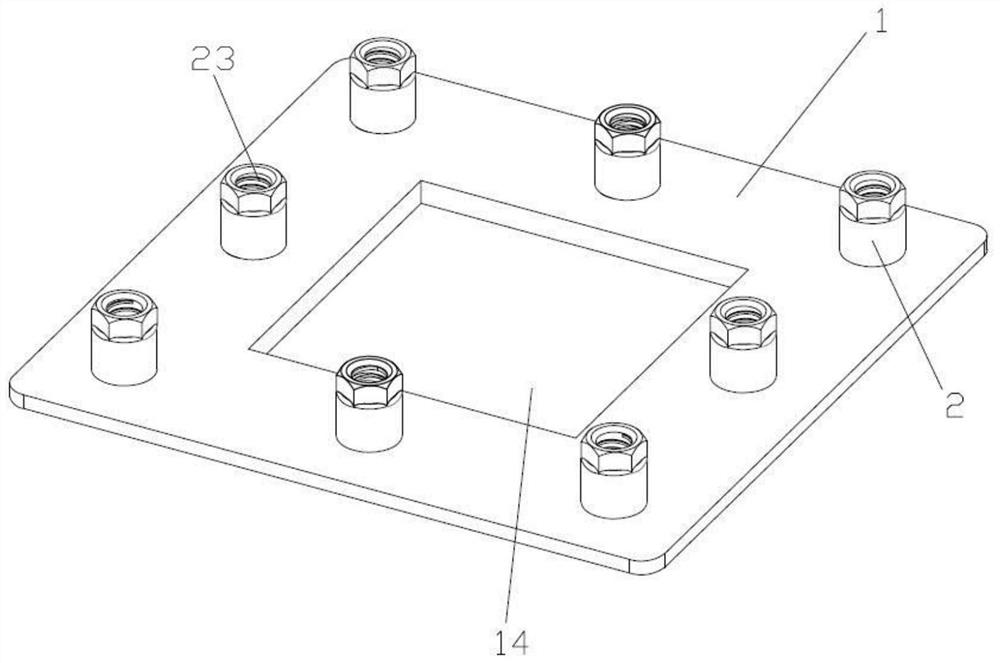

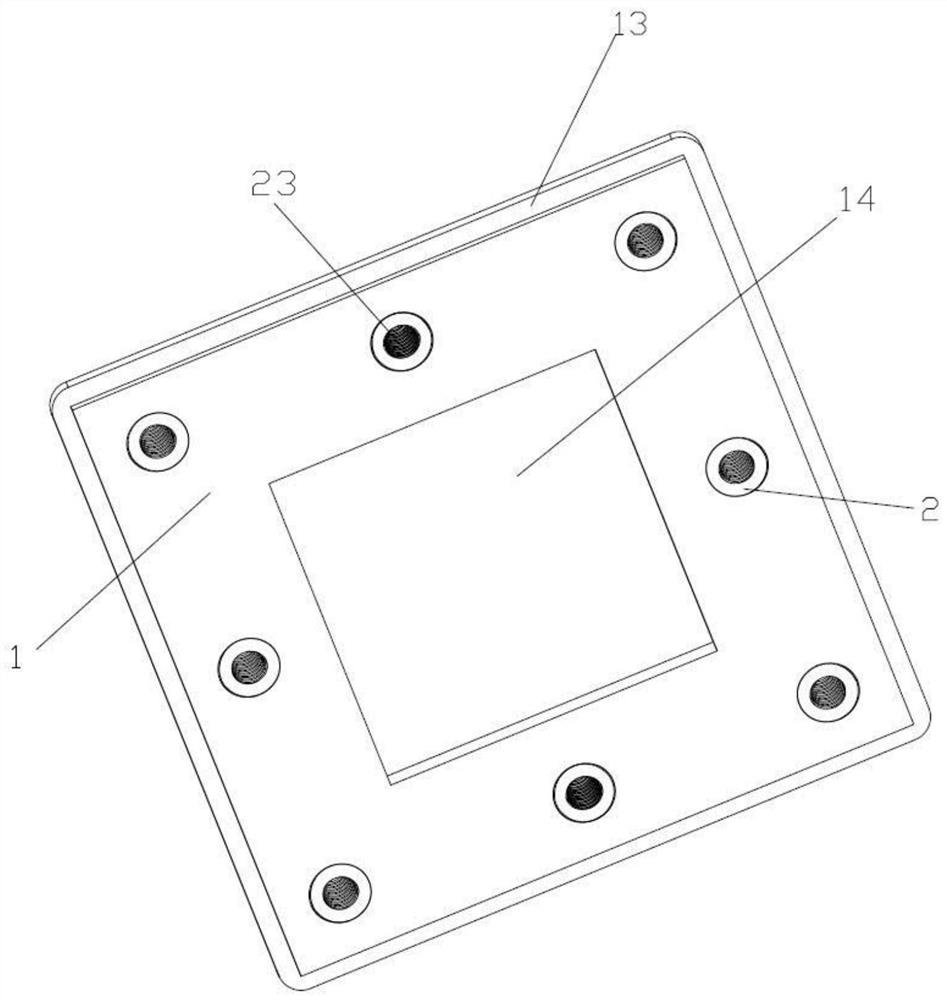

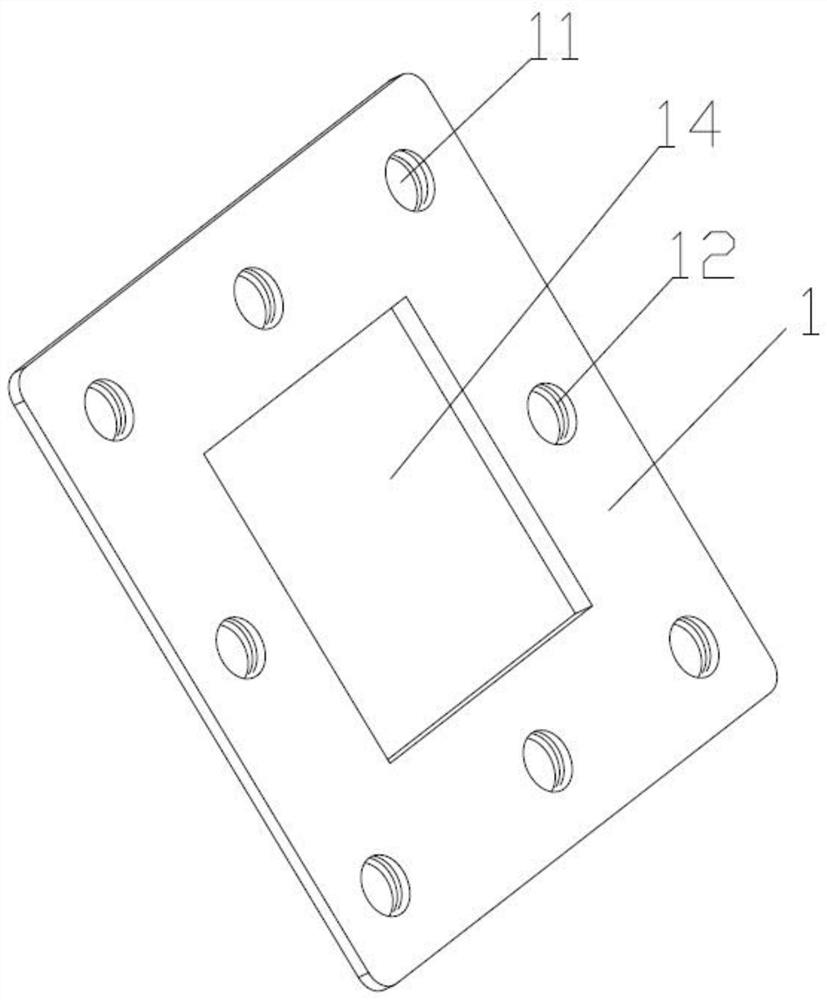

[0034] Such as Figures 1 to 4 As shown, a combined end plate includes an end plate 1, and the edge of the end plate 1 is provided with a plurality of evenly distributed mounting holes 11, and the mounting holes 11 are provided with internal threads 12, and also includes a plurality of connecting pieces 2 One, wherein the connector 2 can be a bolt, one end of each bolt 2 is provided with an external thread 21, and the bolt 2 is screwed with the internal thread 12 of the mounting hole 11 through the external thread 21, and the bolt 2 is provided with an anchor counterbore 22 and Internal thread 2 23, when installing, the steel bar heading of the PC prestressed main s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com