Supercharger provided with switching valve

A technology of mechanical supercharger and switch valve, applied in mechanical equipment, machine/engine, engine components, etc., can solve the problem of high manufacturing cost of diaphragm spring, increase of ball opening pressure, and poor exhaust of pressure relief valve, etc. problems, to expand the pressure relief path, reduce the pressure relief resistance, improve the service life and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

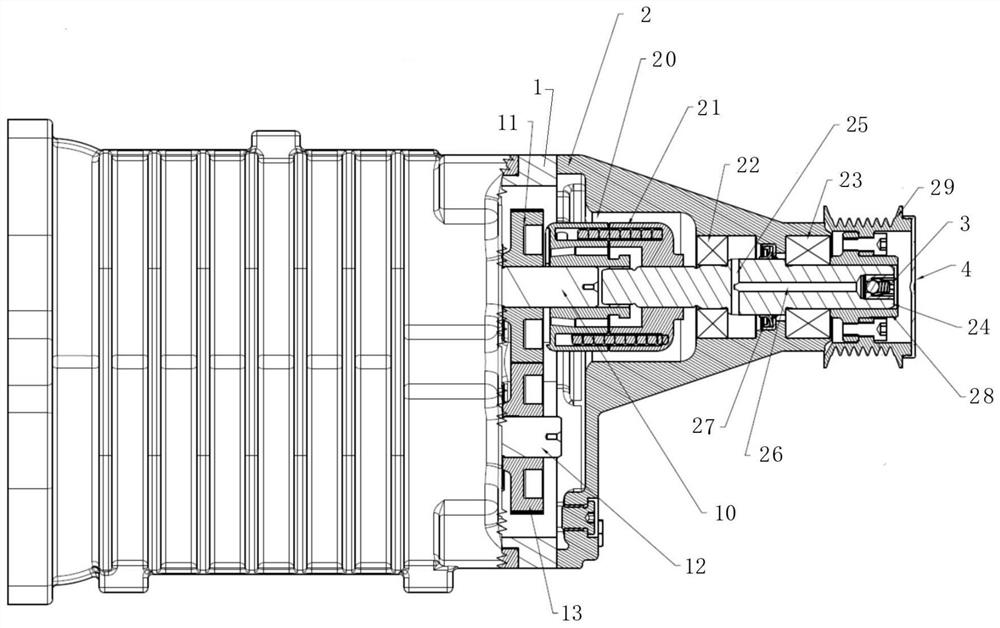

[0032] like Figure 1-3 As shown, the present invention discloses a supercharger provided with an on-off valve, including a bearing plate 1 , a cover plate 2 and an on-off valve 3 .

[0033] In this embodiment, a driving shaft 10 and a driven shaft 12 are installed on the bearing plate 1 respectively. The driving shaft 10 and the driven shaft 12 are respectively equipped with a driving gear 11 and a driven gear 13 which mesh with each other.

[0034] In this embodiment, the bearing plate 1 and the cover plate 2 are sealed and connected to form a lubricating chamber 20 . A bearing 1 22 and a bearing 2 23 are coaxially arranged in the lubricating chamber 20, and a driving shaft 24 is penetrated in the bearing 1 22 and the bearing 2 23, and a coupling is passed between the front end of the driving shaft 24 and the rear end of the drive shaft 10 21 are connected. An oil seal 27 capable of separating the first bearing 22 and the second bearing 23 is provided between the first be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com