Detection apparatus and detection method for machine tool abnormality

An anomaly detection and tool technology, applied in the direction of measuring devices, manufacturing tools, computer control, etc., can solve the problems of reduced productivity, increased machine tool maintenance costs, reduced processing precision, etc., to achieve maximum reliability and accuracy, small The incidence of defective products and the effect of reducing non-processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

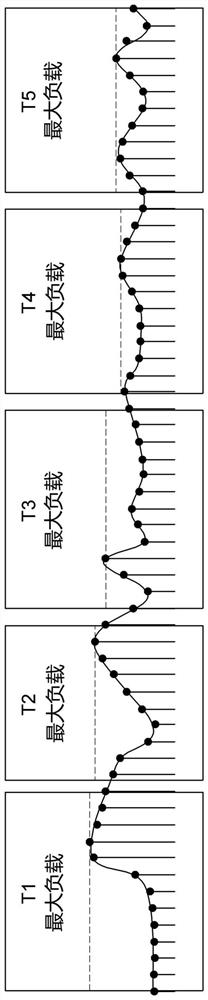

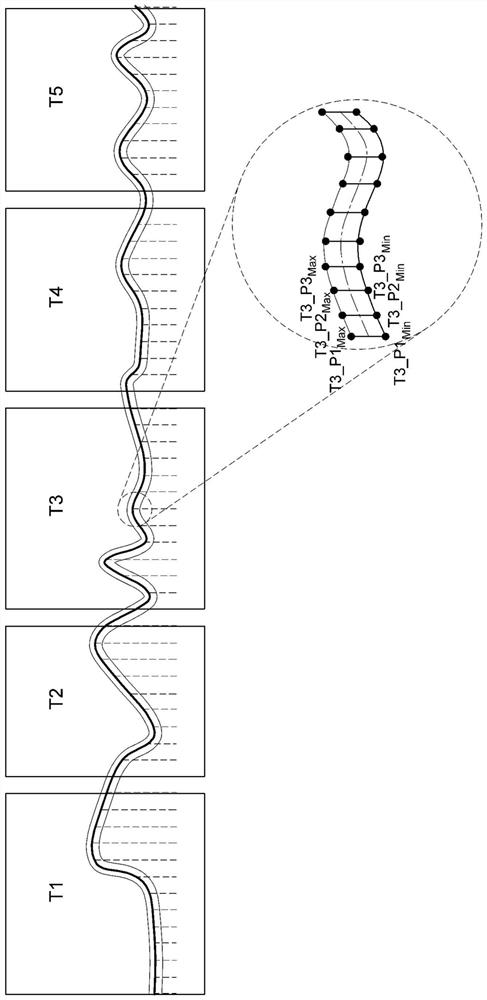

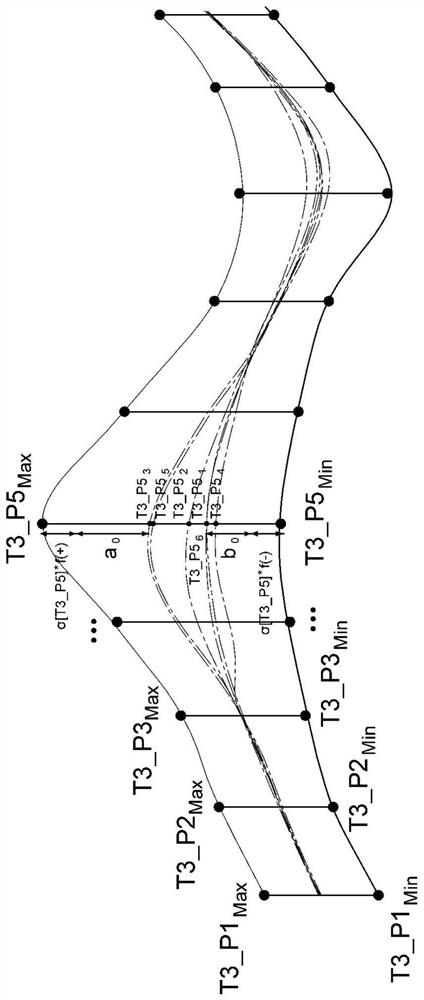

[0042] Hereinafter, a detailed description will be given with reference to diagrams of a tool abnormality detection device and a detection method for a machine tool according to an embodiment of the present invention. The embodiments described below are provided as examples to fully convey the idea of the present invention to those skilled in the art. Therefore, the present invention is not limited to the embodiments described below, but can be embodied in other forms. In addition, in the drawings, the size, thickness, etc. of the device may be shown enlarged for convenience. Throughout the specification, the same symbols denote the same constituent elements.

[0043] The advantages, characteristics, and means for achieving these of the present invention will be clarified by the accompanying drawings and the embodiments described later. However, the present invention is not limited to the following examples, and can be embodied in other various forms. This embodiment is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com