Device for preparing perfumed gathering material

A flavoring and forming device technology, applied in the field of tobacco, can solve the problems affecting product quality, the position of flavoring material cannot be fixed, and the flavoring material is easy to leak, etc., to achieve the effect of product quality improvement, stable feeding, and not easy to leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

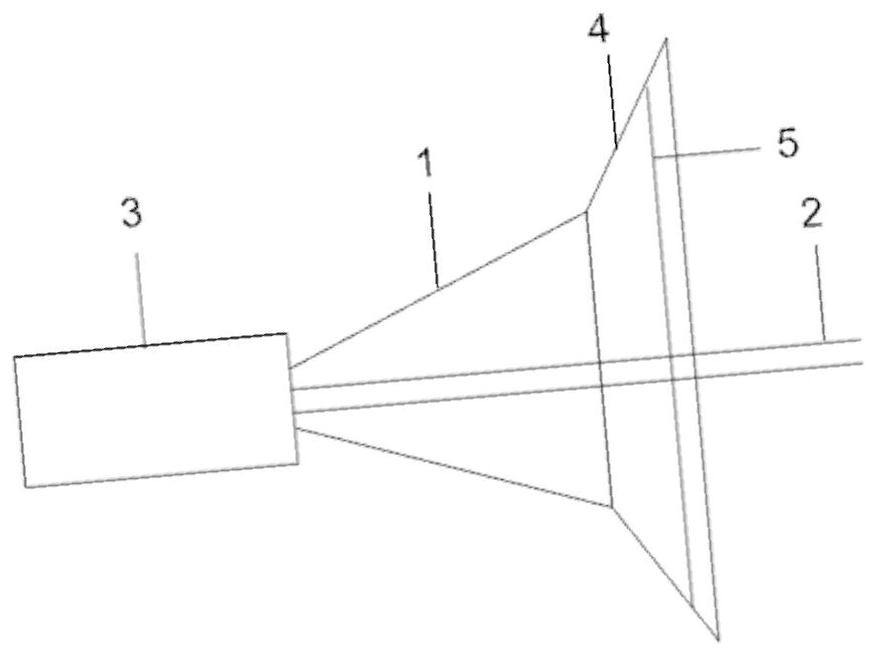

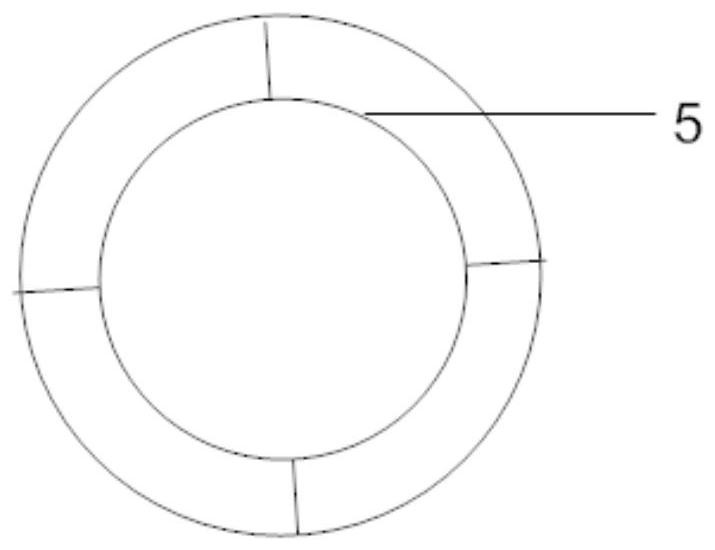

[0025] like figure 1 As shown, the present invention is a device for preparing a fragrant gathering material, which is used for the gathering material being a strip-shaped film, and the flavouring material being a flavoured fiber. It includes a gathering channel 1 of cooling material and an aromatizing channel 2 , wherein the aromatizing channel 2 is located on the centerline of the gathering channel 1 . The gathering channel 1 is a cylinder with a tapered diameter, the larger end of the cylinder is the feed port, the smaller end of the cylinder is the discharge port, and the discharge port is connected to the base rod forming device 3; The incense channel 2 is a circular groove. The height of the feed port of the gathering channel 1 is slightly higher than the discharge port. If the height of the feed port is 5° higher than the horizontal plane, the feed port of the gathering channel 1 has a trumpet-shaped opening 4. There is a feed holder 5 on the opening. The trumpet-sha...

Embodiment 2

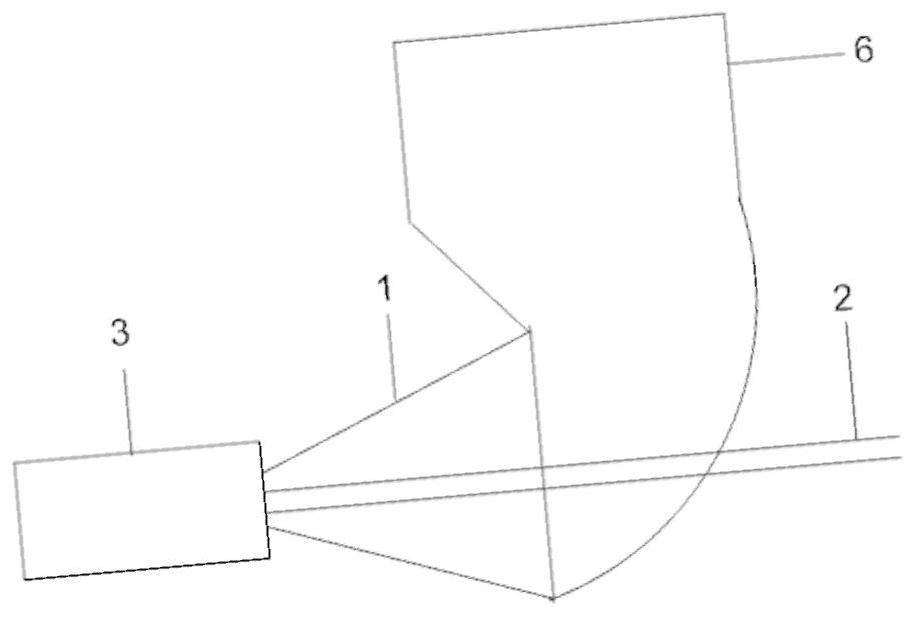

[0028] With Embodiment 1, the difference is that the device of this embodiment has a storage bin, see attached image 3 . Both the gathering material and the aromatizing material in this embodiment are in the form of granules. This example is used for the preparation of the aromatizing and cooling base rod of the patent CN2017107859109, but the aromatizing material is at the center of the base rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com