Protective mask

A mask and body technology, applied in the field of sanitary products, can solve the problems of easy damage of valve pieces, waste of resources, cause infection, etc., and achieve the effects of reducing the use cost, improving the service life, and having a simple structure of the valve core.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

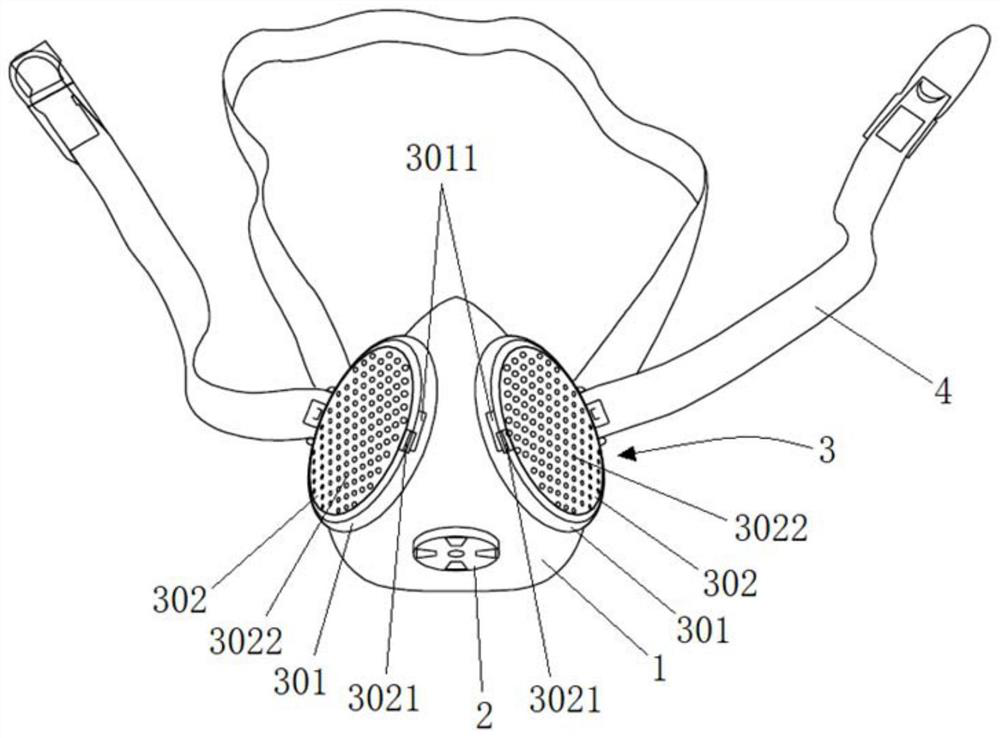

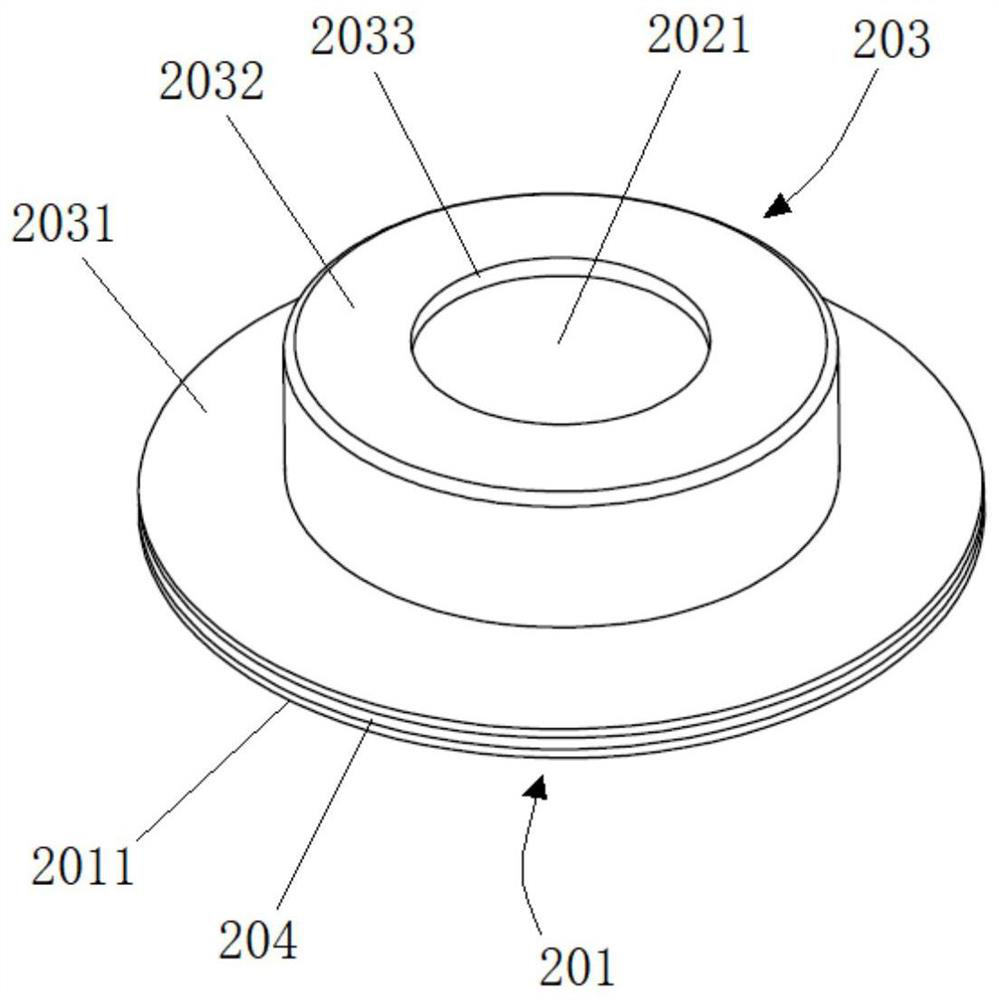

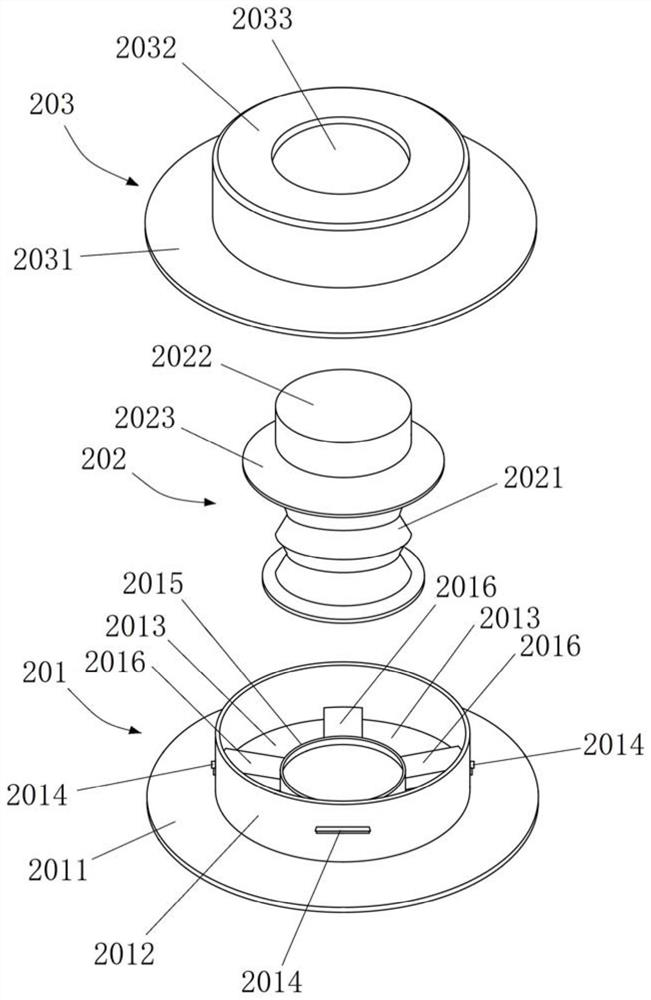

[0060] Such as Figure 1 to Figure 6 As shown, the present invention provides a protective mask, which includes a mask body 1, a breathing valve 2 that is arranged on the mask body 1 and is unidirectionally conducted from the inside of the mask body 1 to the outside of the mask body 1, and fixes the mask body 1, the fixing belt 4, wherein: the fixing belt 4 is arranged on the mask body 1, and a breathing valve installation hole is opened in the lower middle position of the mask body 1, and the breathing valve 2 is fixedly arranged at the breathing valve installation hole; the breathing valve 2 includes a valve Seat 201, spool 202 and bonnet 203, bonnet 203 is arranged on the top of valve seat 201, bonnet 203 is connected with valve seat 201 detachably, is formed between the bottom of bonnet 203 and the top of valve seat 201 Breathing chamber, valve cover 203 is provided with a first vent hole 2033 communicating with the breathing chamber, valve seat 201 is provided with a seco...

Embodiment approach 2

[0085] Such as Figure 7 As shown, the present invention provides a kind of protective mask, and this protective mask comprises mask body 1, fixing band 4 and the breathing valve 2 of above-mentioned structure, and wherein: fixing band 4 is arranged on the mask body 1, and breathing valve 2 is arranged at mask body 1; in addition, the protective mask also includes an annular mask 5, a fan 6 and a fixing ring 7 that match the contour of the wearer's face, the fan 6 is used to reduce the inhalation resistance, and the fixing ring 7 is used to fix the fan 6, Fan 6 is fixedly arranged in the hollow position of fixed ring 7 middle parts, and the annular outer edge of fixed ring 7 is connected with the annular inner edge of mask 5, and the annular outer edge of mask 5 is connected with the inner edge of mouth mask body 1, so that fan 6 is fixed on The inner side of the mask body 1, and the fan 6 is aligned with the first ventilation hole 2033 of the breathing valve 2. Through the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com