Building wood board bonding device and using method

A bonding device and a technology for construction, which are used in the joining of wooden veneers, adhesive application devices, and devices for applying liquid to surfaces, etc., can solve the problems of reduced work efficiency, low work efficiency, inconvenience, etc. The effect of reducing labor intensity, improving work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

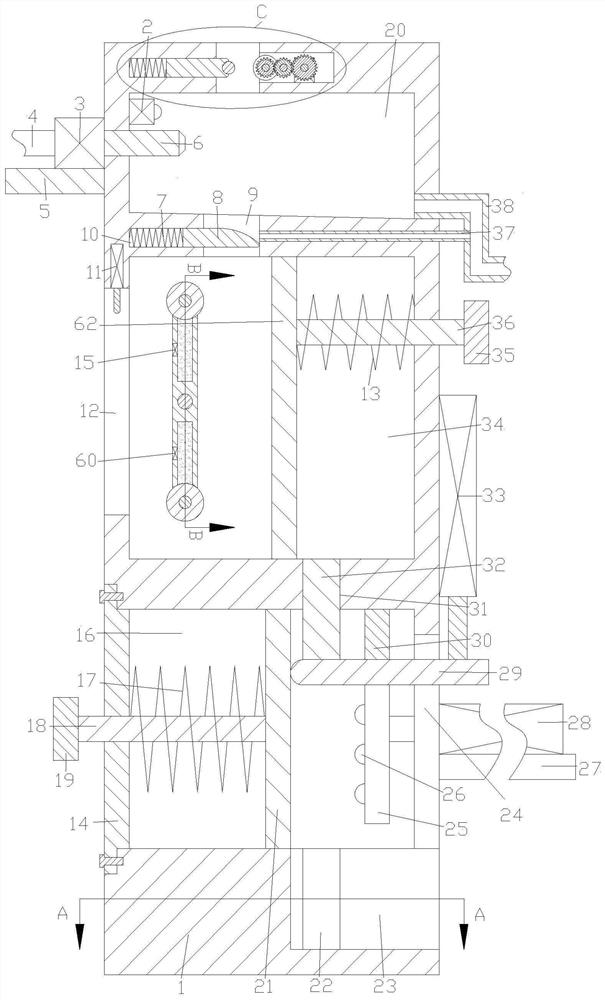

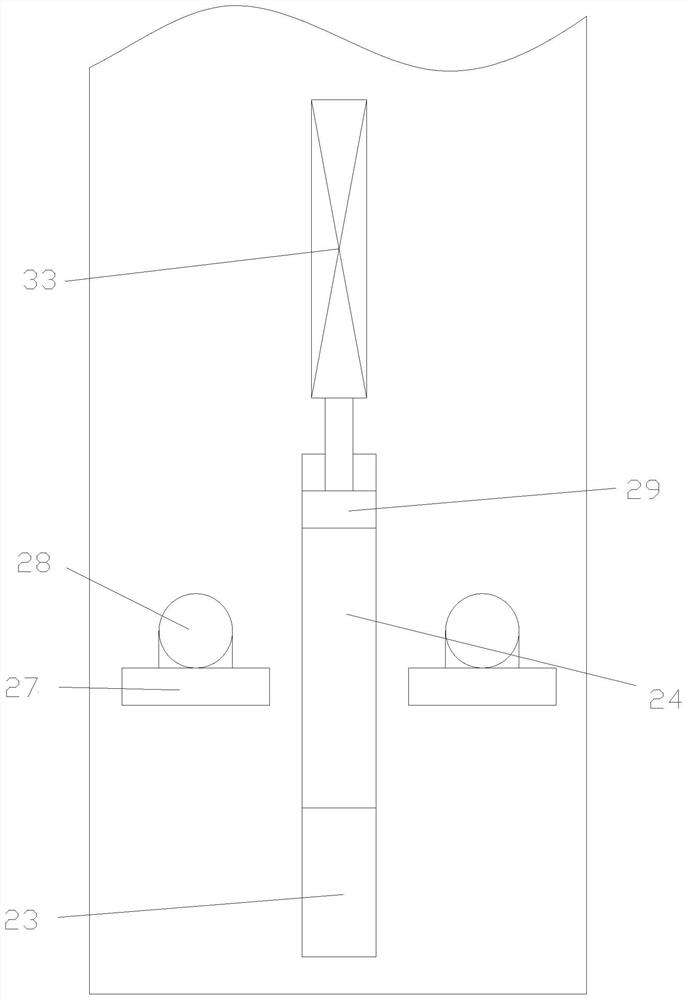

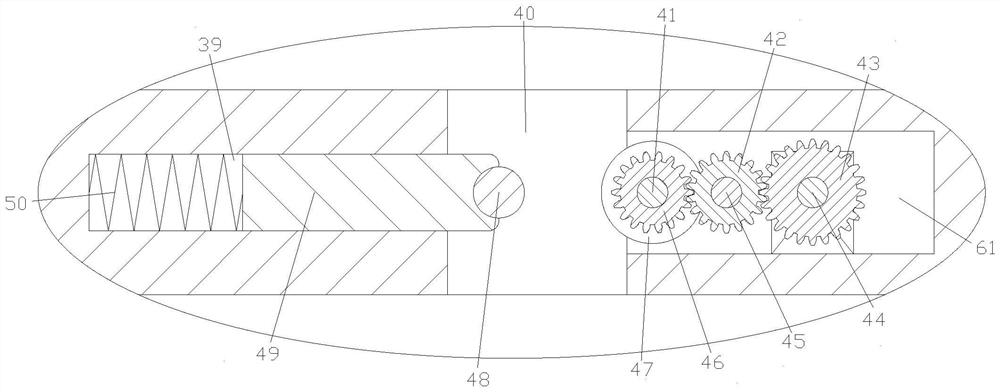

[0025] The present invention will be further explained below in conjunction with the drawings:

[0026] Reference attached figure 1 , 2 , 3, 4, 5, 6, 7: The wooden board bonding device for construction in this embodiment includes a box body 1, and the box body 1 is provided with a glue spray cavity 20 and a pressing cavity from top to bottom. 34. The collection chamber 16, the top of the glue spray chamber 20 is provided with a feed port 40, a first support plate 5 is fixedly mounted on the outside of the box body 1, and a pump body 3 is fixedly mounted on the top of the first support plate 5, The pump body 3 is equipped with a spray head 6 passing through the left end of the glue spraying cavity 20, and the pump body 3 is equipped with a first pipe 4 located outside the box body 1. The bottom of the glue spraying cavity 20 is from left to right. From high to low slope, the bottom of the glue spray cavity 20 is provided with a first feed opening 9 communicating with the pressing ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap