Washing-free reactive dye printing treatment liquid and application thereof

A reactive dye and water-free technology, which can be used in transfer printing, printing, dyeing, etc., and can solve the problems of cumbersome preparation of water-based coloring layer coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

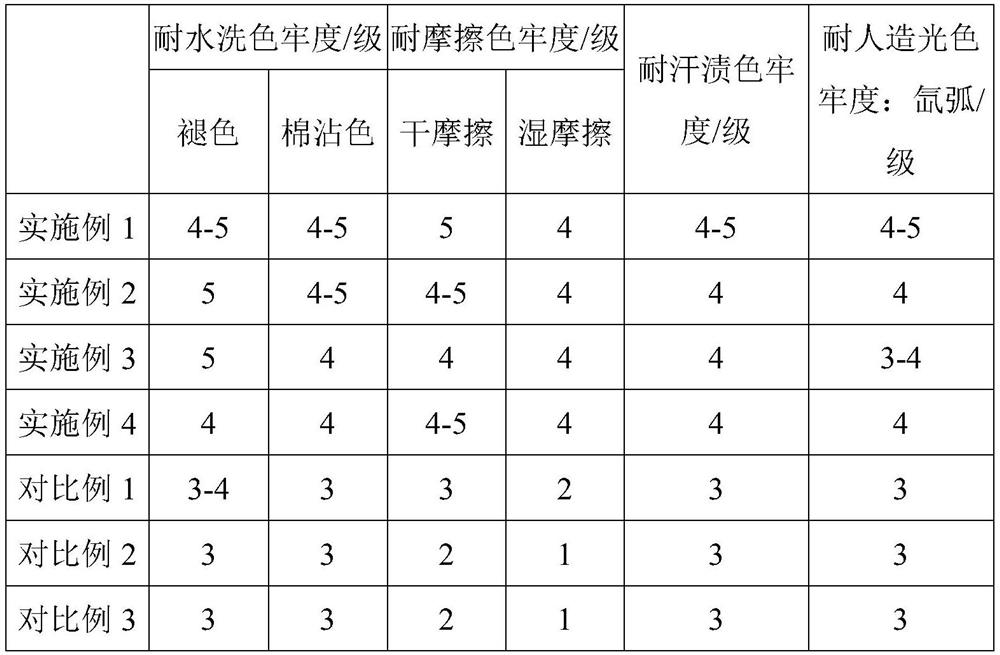

Examples

Embodiment 1

[0028] This embodiment provides a kind of water-free reactive dye printing treatment solution, which is based on its total weight, and is composed of the following components in weight percentage: oxazoline type crosslinking agent: 10%, water-based polyurethane emulsion: 50%, and the remaining The amount is water. Among them, the oxazoline type crosslinking agent is crosslinking agent XH-500, and the average particle size of the water-based polyurethane emulsion is 95nm; the viscosity is 5.3mP·s.

[0029] The preparation method of this water-free reactive dye printing treatment liquid comprises:

[0030] According to the weight percentage of the treatment solution, first dilute 10% of the crosslinking agent XH-500 with an equal amount of deionized water, stir evenly, and then add it to 50% of the water-based polyurethane emulsion to replenish water to 100%.

[0031] This embodiment also provides a method of using the above no-wash reactive dye treatment solution to carry out ...

Embodiment 2

[0035] This embodiment provides a kind of water-free reactive dye printing treatment solution, which is based on its total weight and consists of the following components in weight percentage: isocyanate crosslinking agent: 5%, water-based polyacrylate emulsion: 50%, the balance for water. Among them, the isocyanate crosslinking agent is crosslinking agent SD-235, and the average particle size of the aqueous polyacrylate emulsion is 90nm; the viscosity is 6.1mP·s. The preparation method of this water-free reactive dye printing treatment liquid comprises:

[0036] According to the weight percentage of the treatment solution, first dilute 5% of the crosslinking agent SD-235 with an equal amount of deionized water, stir evenly, and then add it to 50% of the water-based polyacrylate emulsion to replenish water to 100%.

[0037] According to the method of Example 1, the cotton fabric was printed with the no-wash reactive dye using the no-wash reactive dye treatment solution of thi...

Embodiment 3

[0039] This embodiment provides a no-wash reactive dye printing treatment solution, which is based on the total weight and consists of the following components in weight percentage: aziridine crosslinking agent XR-2500: 5%, oxazoline type crosslinking agent XR -5510: 5%, water-based polyurethane emulsion: 50%, the balance is water. Among them, the average particle size of the water-based polyurethane emulsion is 95nm; the viscosity is 5.3mP·s.

[0040] The preparation method of this water-free reactive dye printing treatment liquid comprises:

[0041] According to the weight percentage of the treatment solution, first dilute 5% of the aziridine crosslinking agent XR-2500 and 5% of the oxazoline crosslinking agent XR-5510 with an equal amount of deionized water, stir evenly, and then Add to 50% water-based polyurethane emulsion to replenish water to 100%.

[0042] According to the method of Example 1, the cotton fabric was printed with the no-wash reactive dye using the no-wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com