A kind of polyionic liquid-cerium oxide compound catalyst and its preparation method and application

A technology of polyionic liquid and oxygen compound, which is applied in the field of polyionic liquid-cerium oxygen compound catalyst and its preparation, can solve the problems of complicated urea process, etc., and achieves the improvement of conversion rate and selectivity, excellent catalytic performance, and good capture effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] After adding 200mmol 4-vinylbenzyl chloride and 50mmol TMPDA into the reactor to dissolve, N 2 Under protection, react at 70°C for 12 hours to prepare monomers, then add 0.8 g of azobisisobutyronitrile and stir to obtain polyionic liquid gel P[C 3 DVBTMA] [Cl]. Get 5mmol of this polyionic liquid and add 40mmol Ce(NO 3 ) 3 ·6H 2 O and H 2 O, then add Na 2 CO 3 Adjust the pH to 9, stir for 10h, filter the precipitate, wash, dry, and roast to obtain the polyionic liquid-cerium oxide catalyst P[C 3 DVBTMA][Cl]-Ce-8.

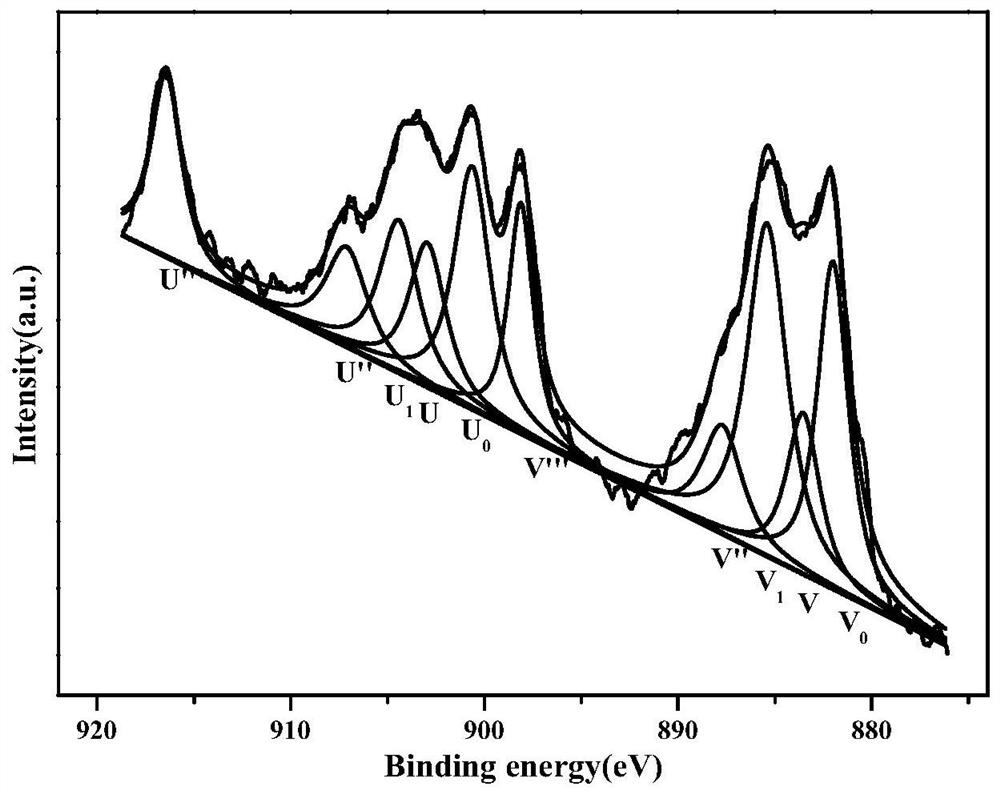

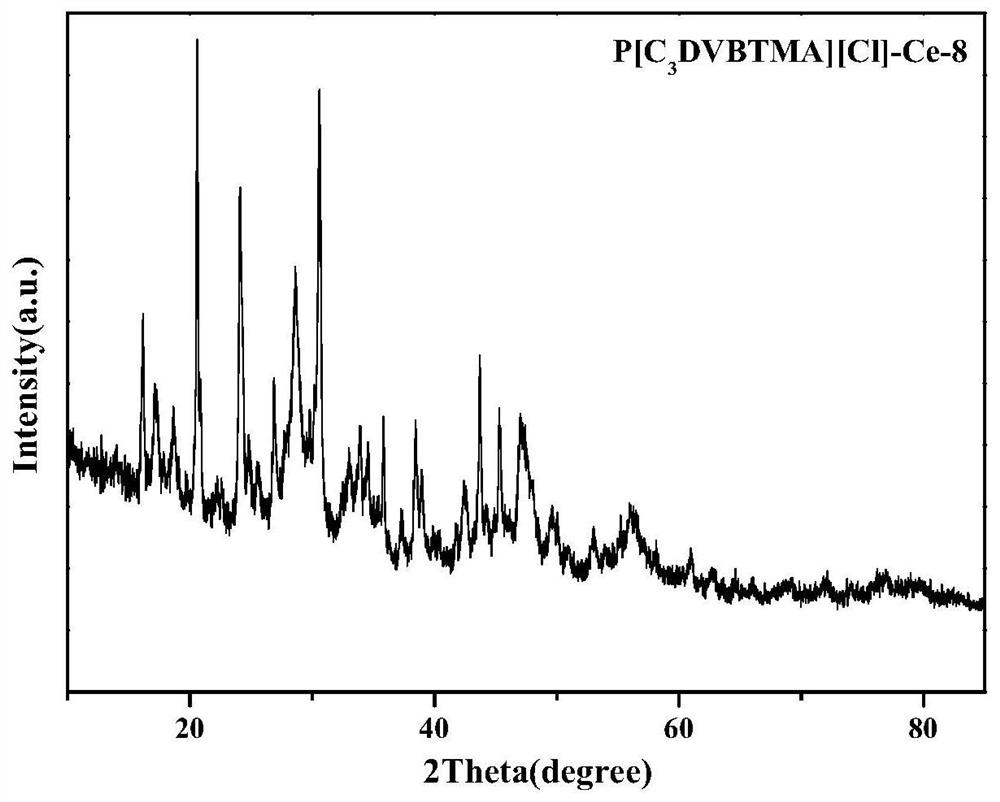

[0028] P[C 3 DVBTMA][Cl]-Ce-8, Ce 3+ The molar content accounts for 55.8% of the total amount of Ce elements, and the catalyst XPS figure is shown infigure 1 , according to Ce3 + / (Ce 3+ +Ce 4+ ) = area(u 1 , u 0 ,v 1 ,v 0 ) / total area for calculation, namely Ce 3+ corresponding u 1 , u 0 and v 1 , v 0 The ratio of the area of the fitted peak to the sum of the areas of all fitted peaks; the catalyst XRD pattern is shown in figure 2 , w...

Embodiment 2

[0031] After adding 200mmol 4-vinylbenzyl chloride and 50mmol TMPDA into the reactor to dissolve, N 2 Under protection, react at 70°C for 12 hours to prepare monomers, then add 0.8 g of azobisisobutyronitrile and stir to obtain polyionic liquid gel P[C 3 DVBTMA] [Cl]. Get 5mmol of this polyionic liquid and add 20mmol Ce(NO 3 ) 3 ·6H 2 O and H 2 O, after adding NaHCO 3 Adjust the pH to 9, stir for 10h, filter the precipitate, wash, dry, and roast to obtain the polyionic liquid-cerium oxide catalyst P[C 3 DVBTMA][Cl]-Ce-4.

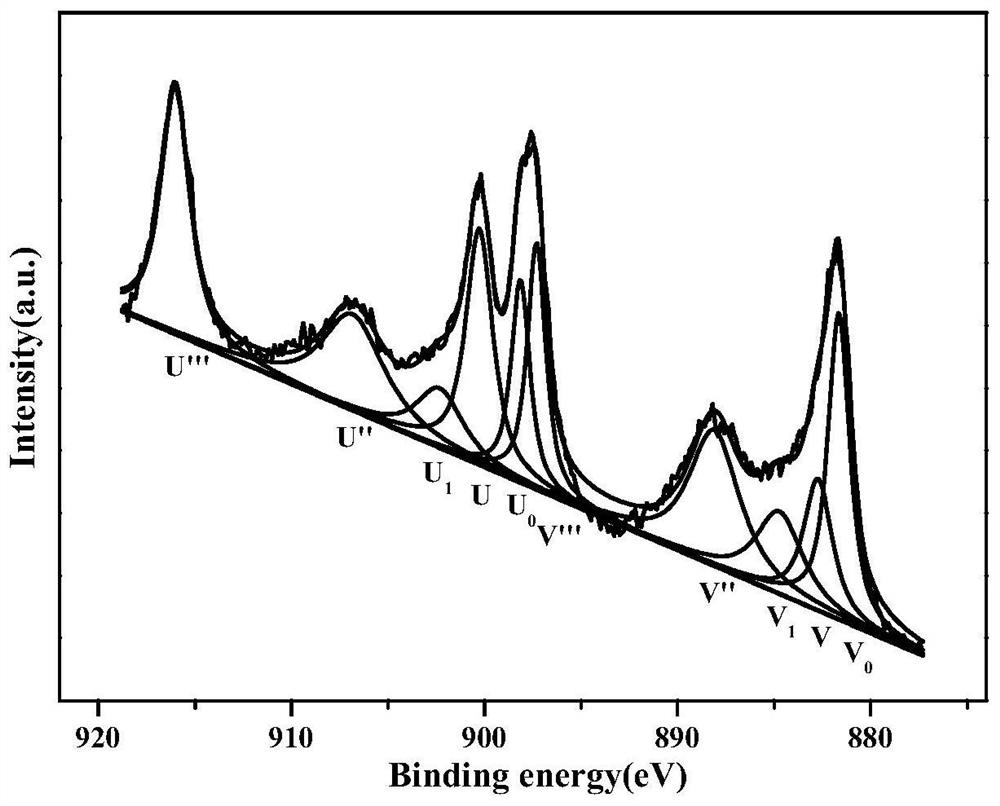

[0032] P[C 3 DVBTMA][Cl]-Ce-4, Ce 3+ The molar content of Ce accounts for 54.9% of the total amount of Ce elements, and its composition is CeO 2 and Ce 2 O(CO 3 ) 2 ·H 2 O.

[0033] Catalyst P[C 3 DVBTMA][Cl]-Ce-4 for CO 2 In the application of preparing 4-methylpropylene urea with 1,3-butanediamine, add 50mmol 1,3-butanediamine to the reactor, and then fill with 0.5MPa CO 2 , add 0.05g of catalyst, react at 140°C for 6h, the conversion rate...

Embodiment 3

[0035] After adding 200mmol 4-vinylbenzyl bromide and 50mmol TMPDA into the reactor to dissolve, N 2 Under protection, react at 70°C for 12 hours to prepare monomers, then add 1.0 g of azobisisobutyronitrile and stir to obtain polyionic liquid gel P[C 3 DVBTMA] [Br]. Take 5mmol of the polyionic liquid and add 20mmol Ce 2 (SO 4 ) 3 and H 2 O, then add K 2 CO 3 Adjust the pH to 9, stir for 10h, filter the precipitate, wash, dry, and roast to obtain the polyionic liquid-cerium oxide catalyst P[C 3 DVBTMA][Br]-Ce-4.

[0036] P[C 3 DVBTMA][Br]-Ce-4, Ce 3+ The molar content of Ce accounts for 46.4% of the total amount of Ce elements, and its composition is CeO 2 and Ce 2 O(CO 3 ) 2 ·H 2 O.

[0037] P[C 3 DVBTMA][Br]-Ce-4 for CO 2 In the application of preparing propylene urea with 1,3-propylenediamine, add 50mmol 1,3-propylenediamine to the reactor, and then fill it with 0.5MPa CO 2 , add catalyst 0.05g, react at 140°C for 6h, the conversion rate of 1,3-propanediam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com