Salvaging construction method for dynamic compaction hammer

A technology of rammer and construction method, applied in the field of salvage construction method of dynamic rammer, can solve the problems of uneven thickness of backfilling soft soil, delay of construction period, economic loss, etc., so as to improve the salvage efficiency, ensure the progress of the project, and reduce the construction of the project. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

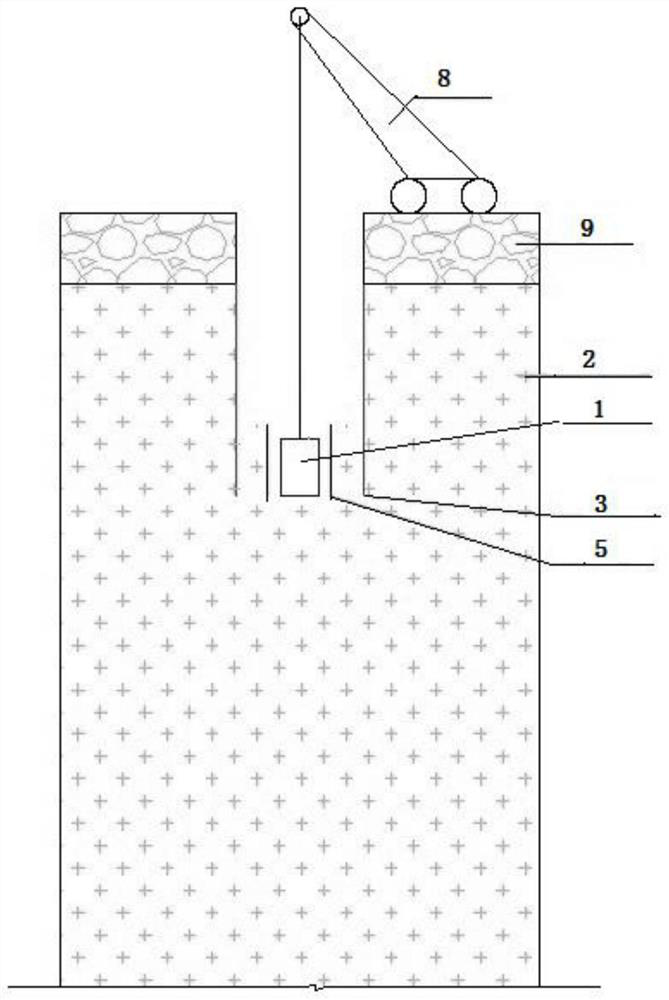

[0036] This embodiment provides a kind of salvage method of a dynamic rammer, such as figure 1 shown, including the following steps:

[0037] Step S1: Find out the position of the rammer 1;

[0038] Step S2: Ascertain the posture of the rammer 1;

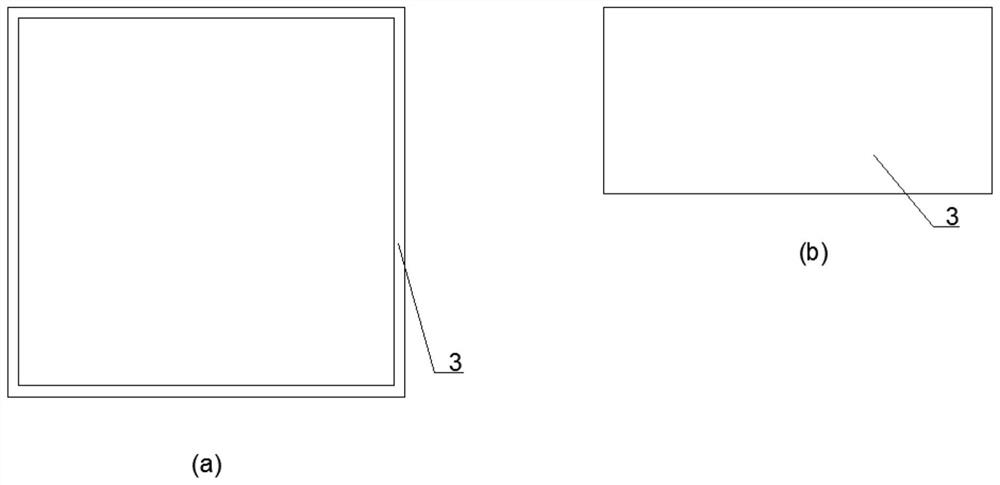

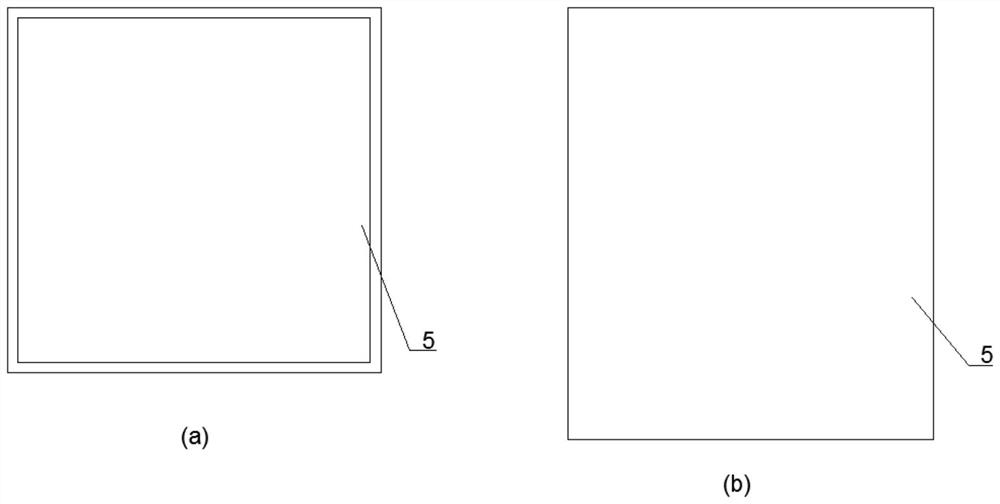

[0039] Step S3: sinking the primary caisson 3 in the soft soil 2 above the rammer 1, and excavating the soft soil 2 in the primary caisson 3;

[0040] Step S4: dig until the handle of the rammer 1 is exposed, and lift the rammer 1 to a safe area.

[0041] The step S2 can also ascertain the attitude of the rammer through an ultrasonic induction scanner, and the specific steps are as follows:

[0042] Step A1, construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com