Basement shear wall post-pouring belt precast external mold construction method

A technology of shear walls and post-pouring belts, which is applied to building components, wine cellars, building insulation materials, etc., can solve problems such as increasing the safety construction risk of foundation pits, affecting the construction quality of post-pouring belts, and increasing the difficulty of basement construction. , to prevent the influx of construction debris and sewage, save labor and energy, and reduce construction safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

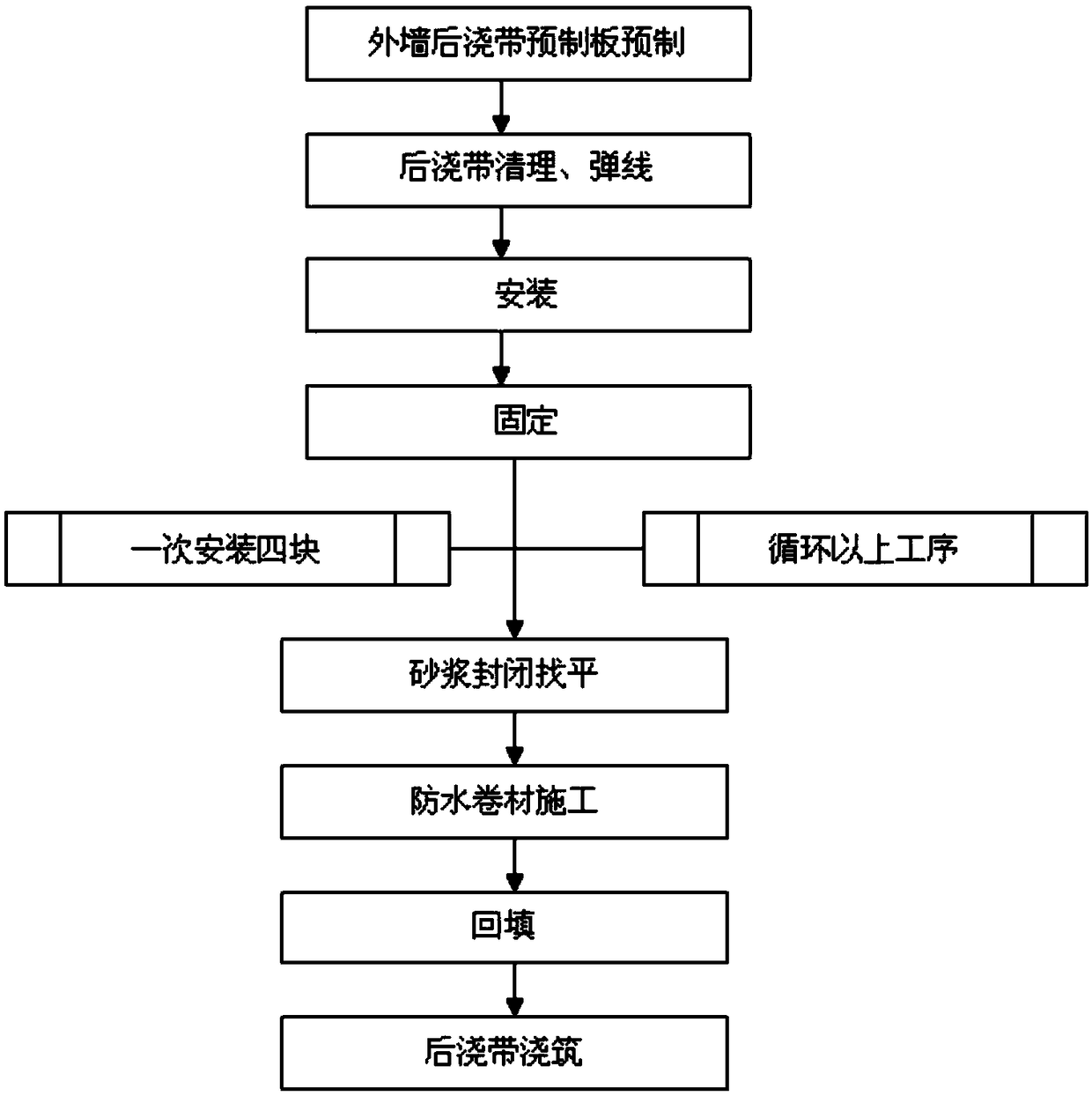

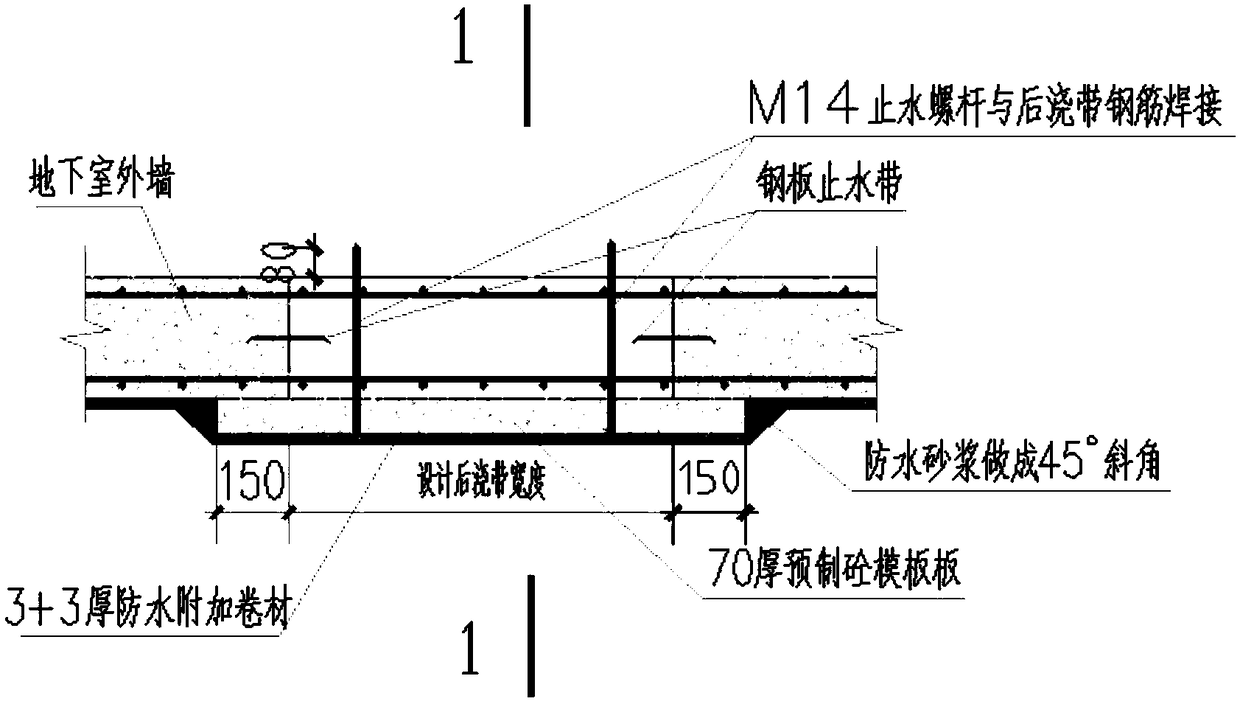

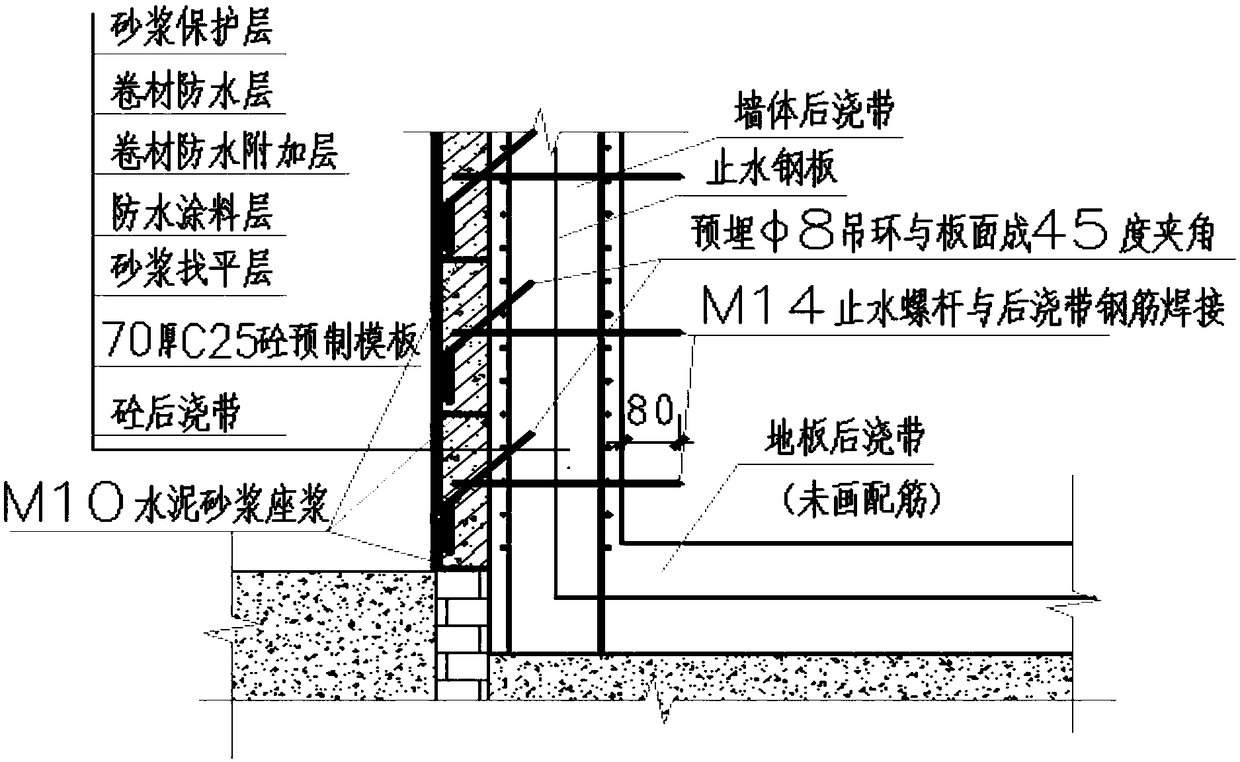

[0033] Such as figure 1 , 2 , 3, 4, 5, and 6 show that the basement shear wall post-casting belt prefabricated external formwork construction method of the present embodiment, the specific steps are as follows:

[0034] After the formwork removal of the shear wall in the basement, remove and clean the floating slurry at the position of the post-cast strip of the shear wall, and then install the prefabricated concrete formwork with M10 cement mortar, and reserve the water-stop screw and the post-cast steel bar of the shear wall Weld the connection, seal the gaps and internal corners between the prefabricated block and the shear wall with waterproof mortar, and paste the waterproof additional layer membrane to the outside of the prefabricated block, and make a protective mortar layer on the waterproof outer side of the membrane;

[0035] According to the basic provisions of 3.4.13 of the "Technical Regulations for Concrete Structures of High-Rise Buildings JGJ3-2010", the width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com