Prefabricated building laminated slab

A laminated board and prefabricated technology, used in buildings, building components, building structures, etc., can solve the problems of large gaps at joints, complicated operations, and easy splicing errors, and achieve the process of stress concentration, uniform distribution, and alignment. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is attached Figure 1-3 The application is described in further detail.

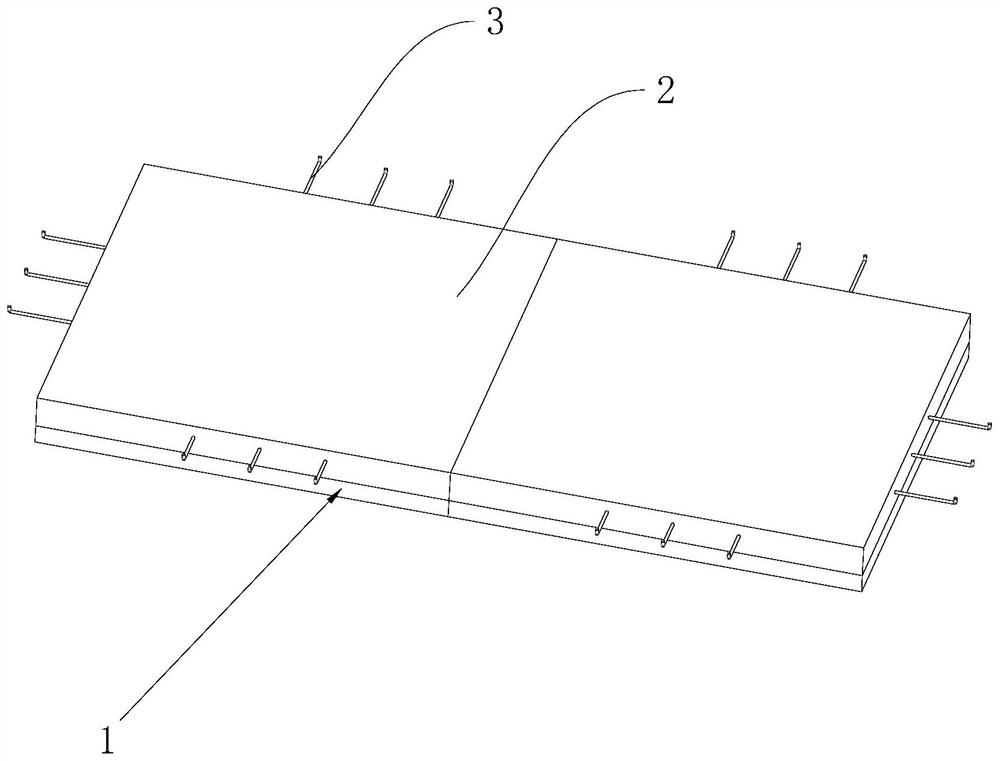

[0036] The embodiment of the present application discloses a prefabricated building composite panel. refer to figure 1 The prefabricated building laminated slab includes a prefabricated rectangular laminated slab body 1 and a pouring slab 2 poured on the laminated slab body 1, and a number of reinforcing steel bars 3 for strengthening the structural strength of the application are perforated in the laminated slab body 1.

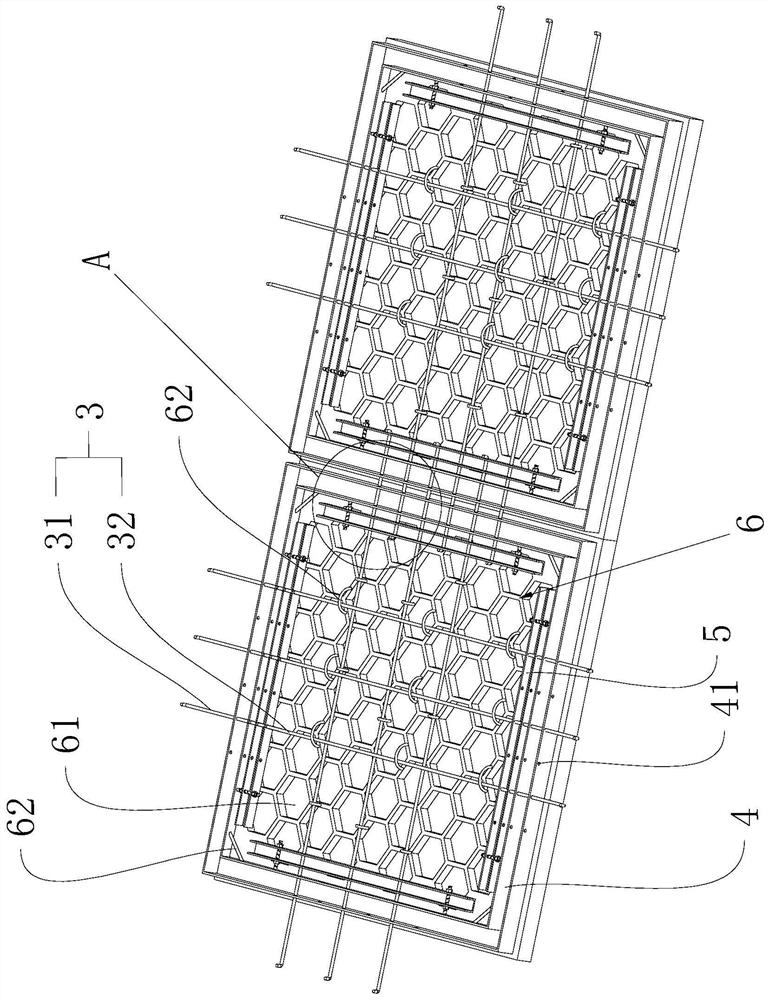

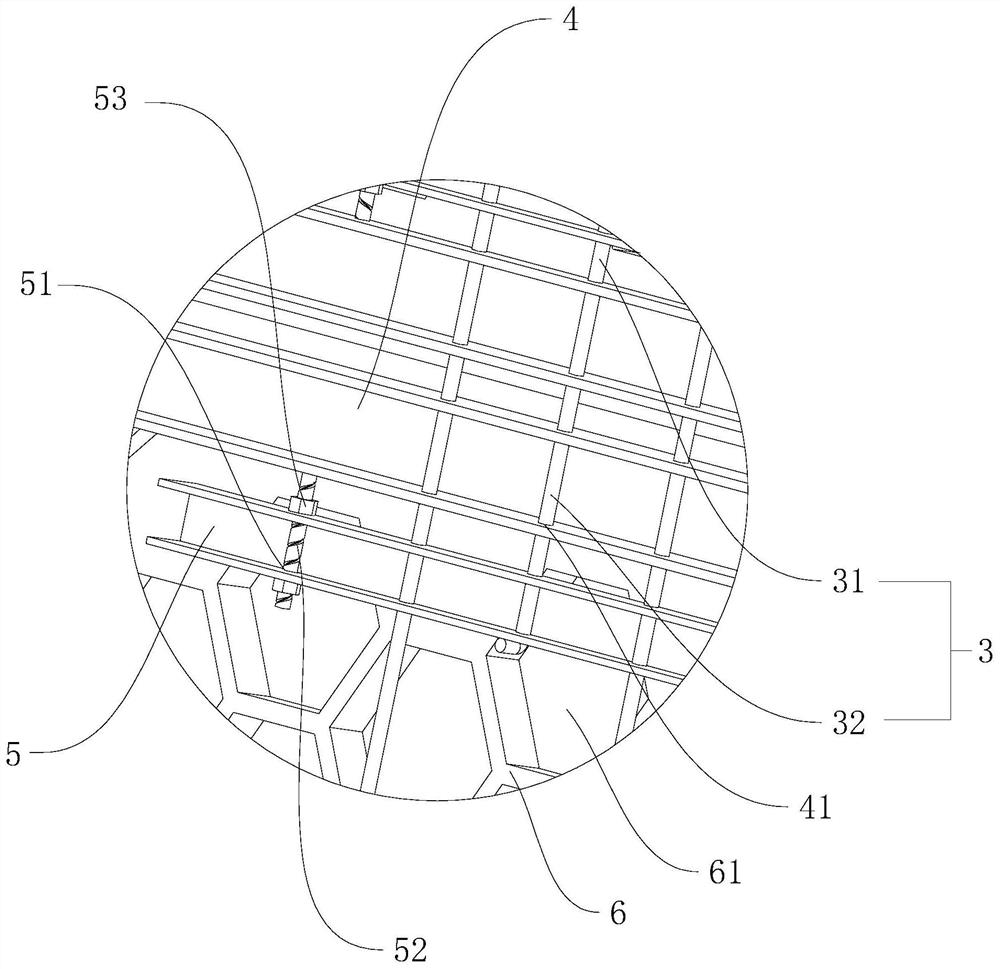

[0037] refer to figure 2 , the bottom of the laminated plate body 1 is provided with a horizontally placed light frame 6, the light frame 6 has a rectangular structure as a whole, and two sets of mutually vertical reinforcement channel steels 4 are welded around the light frame 6, each group of reinforcement channel steels 4. There are only two and parallel to each other. The lightweight frame 6 includes a number of opening slots 61 with hexagonal cross-sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com