Gas injection type rotary detonation ramjet combustion chamber

A technology of ramjet engine and combustion chamber, which is applied in the direction of ramjet engine, deflagration combustion chamber, combustion chamber, etc. It can solve the problems of low engine thrust performance, insufficient engine ramming effect, and inconspicuous air pressurization, etc., to achieve improved mixing effect, improving combustion efficiency, and expanding the range of the flight envelope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Combined with the flight trajectory, when flying at a low Mach number, if the flow captured by the inlet 2 is 4kg / s, the total pressure is 1.5atm±0.2atm.

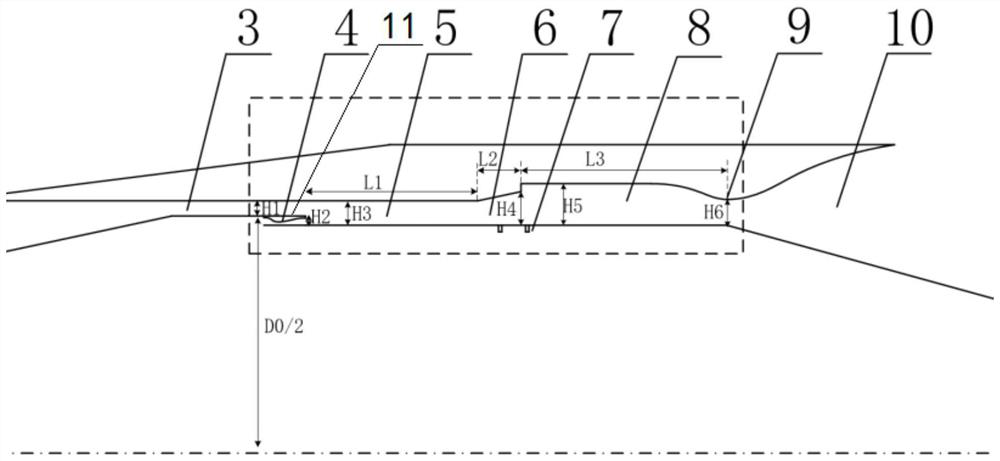

[0045] The length L1 of the mixing channel 5 is in the range of 4.3H3

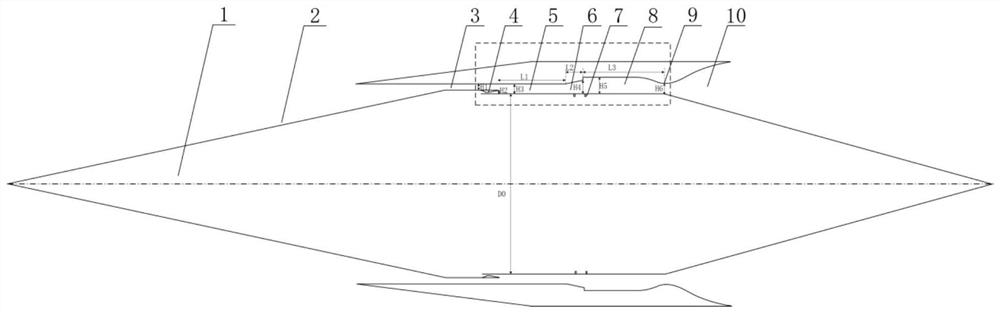

[0046] Such as figure 1 The combustion chamber of a wide-speed-range injection type rotary detonation engine shown is a cavity formed by a hollow cylindrical shell with openings at both ends and a central body 1 arranged in the shell. The cavity Including the intake passage 2, the isolation section passage 3, the mixing passage 5, the expansion passage 6, the combustion chamber cavity 8, the combustion chamber throat 9 and the tail nozzle 10 connected in sequence, the expansion passage 6 and / or the combustion chamber A fuel nozzle 7 is prov...

Embodiment 2

[0055] Combined with the flight trajectory, when flying at a low Mach number, if the flow captured by the inlet 2 is 4kg / s, the total pressure is 2atm±0.2atm.

[0056] The length L1 of the mixing channel 5 is in the range of 3.3H3

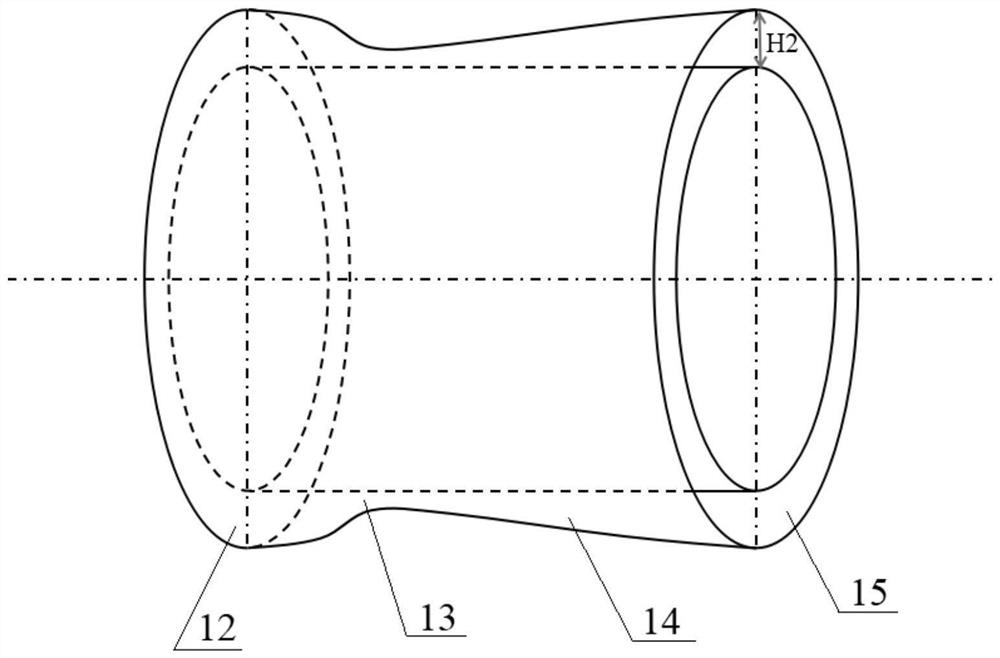

[0057] In this embodiment, the annular rocket 4 consists of eight fan-shaped rockets arranged along the circumferential direction of the central body 1, each responsible for a fan annular gap, and finally the high-temperature and high-pressure gas is ejected through the fan-shaped nozzle 16 with a height of H2. Described annular rocket 4 adopts gas oxygen kerosene rocket.

Embodiment 3

[0059] Combined with the flight trajectory, when flying at a low Mach number, if the flow captured by the inlet 2 is 4kg / s, the total pressure is 1atm±0.2atm.

[0060] The length L1 of the mixing channel 5 is in the range of 5H3

[0061] In this embodiment, the annular rocket 4 consists of twelve fan-shaped rockets arranged along the circumferential direction of the central body 1, each responsible for a fan-shaped annular seam, and finally the high-temperature and high-pressure gas is ejected through the fan-shaped nozzle 16 with a height of H2. Described annular rocket 4 adopts gas oxygen kerosene rocket.

[0062] To sum up, the present invention provides a rotary detonation ramjet combustor with gas ejection. A ring rocket is added to the front of the rotary detonati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com