Compressor inlet guide blade adjustment mechanism and control method thereof

An inlet guide vane and adjustment mechanism technology, which is applied in pump control, machine/engine, mechanical equipment, etc., can solve the problems of increased angle error of the inlet guide vane, easy bending of the connecting rod, and low control accuracy, so as to reduce the complexity. , Improve the accuracy and avoid the effect of control errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

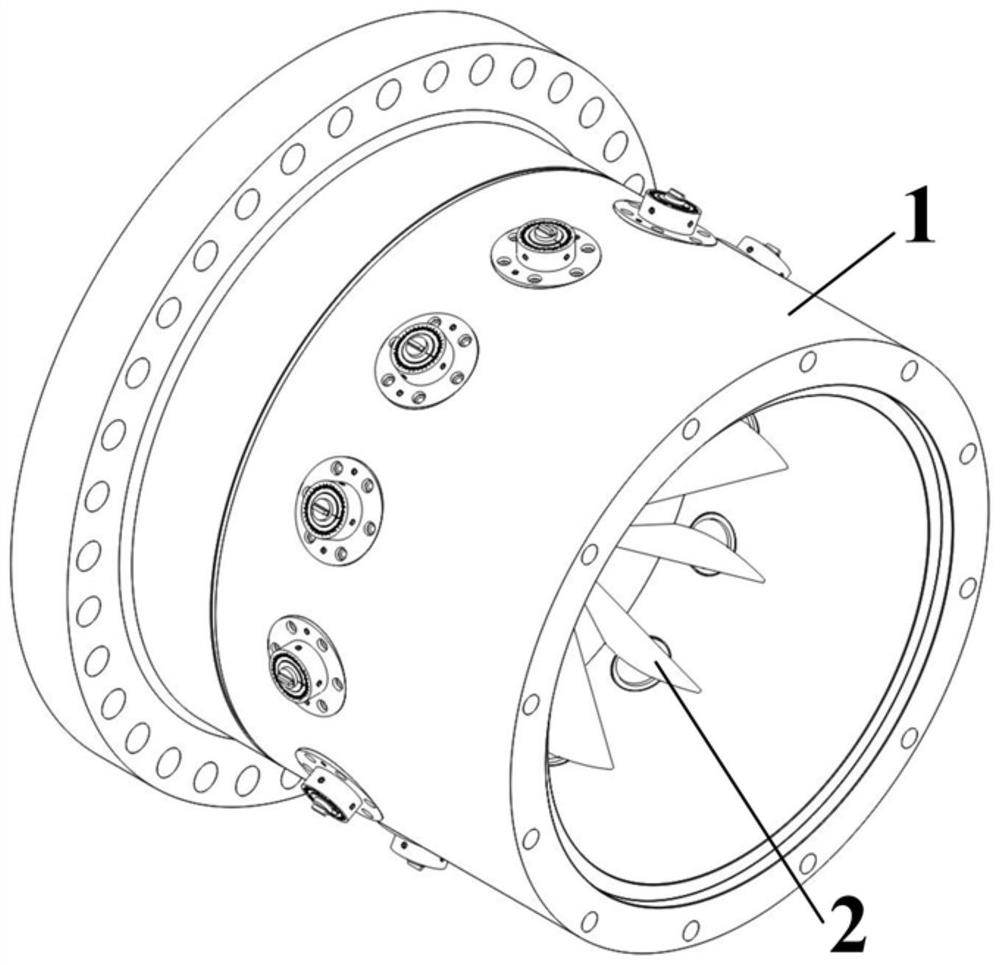

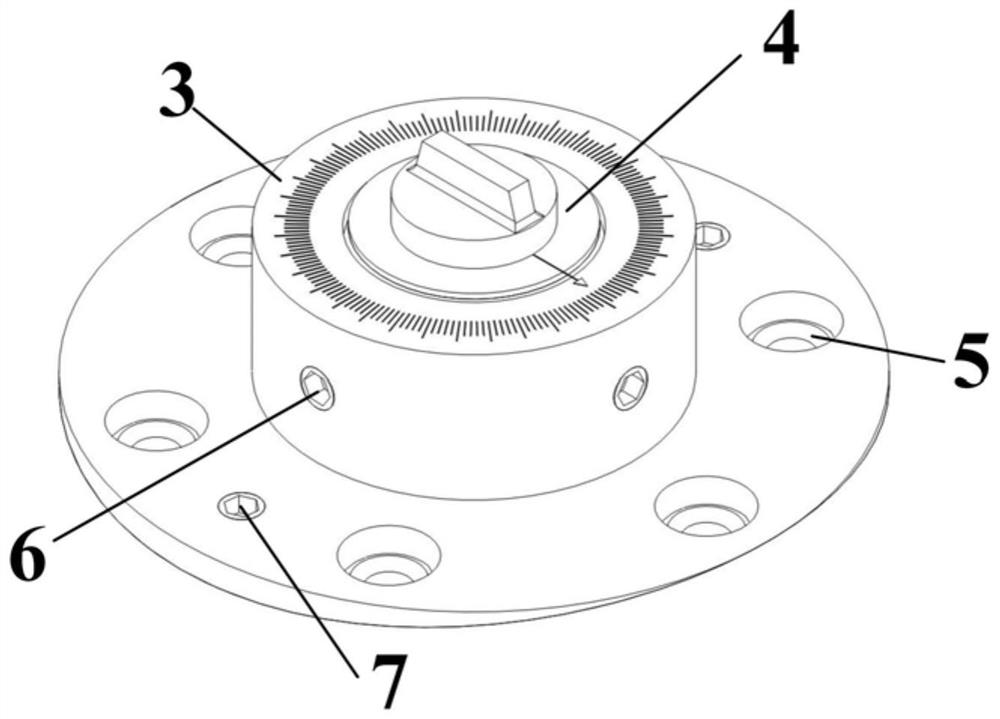

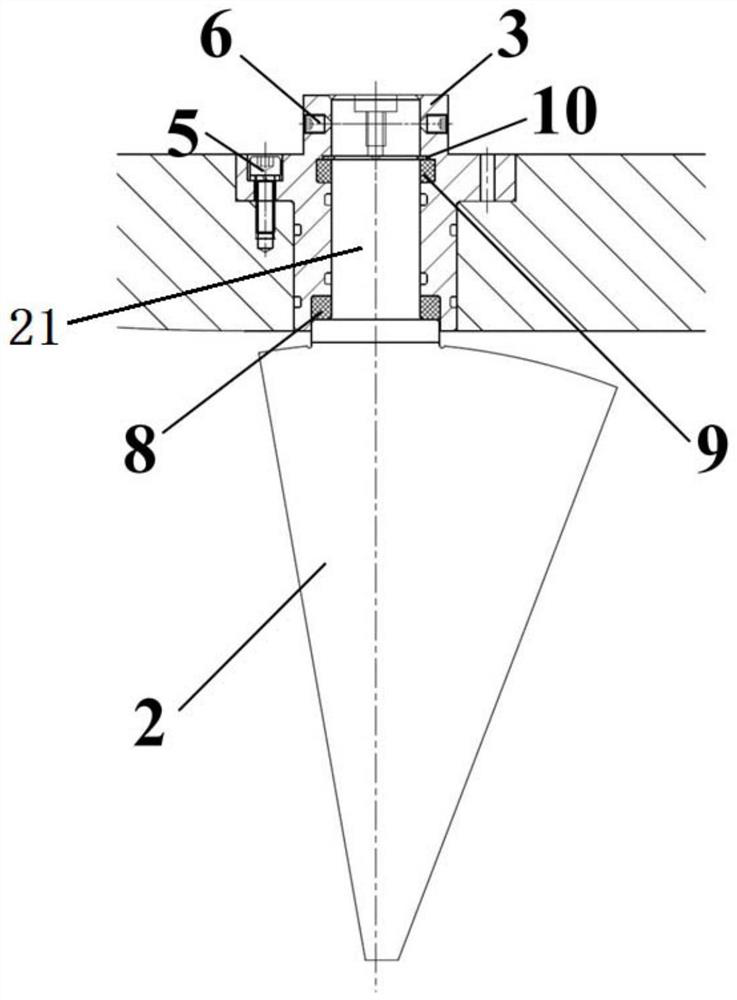

[0034] refer to Figure 1~5 , the compressor inlet guide vane adjustment mechanism proposed by the present invention includes a pressure sleeve 3, a rotating handle 4, a fixing bolt 5, a set screw 6 / 7, a bushing 8 / 9, a washer 10, and uniformly arranged circumferentially on the inlet guide vane. A plurality of inlet guide vane blades 2 on the blade cylinder body 1. The blade root of each inlet guide vane blade 2 is formed as a rotating shaft 21, and the rotation shaft 21 at the blade root of each inlet guide vane blade 2 is all angle-adjustably arranged on the inlet guide vane cylinder through a manual adjustment mechanism. 1 on. Each manual adjustment mechanism at least includes a pressure sleeve 3 and a rotating handle 4, wherein the pressure sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com