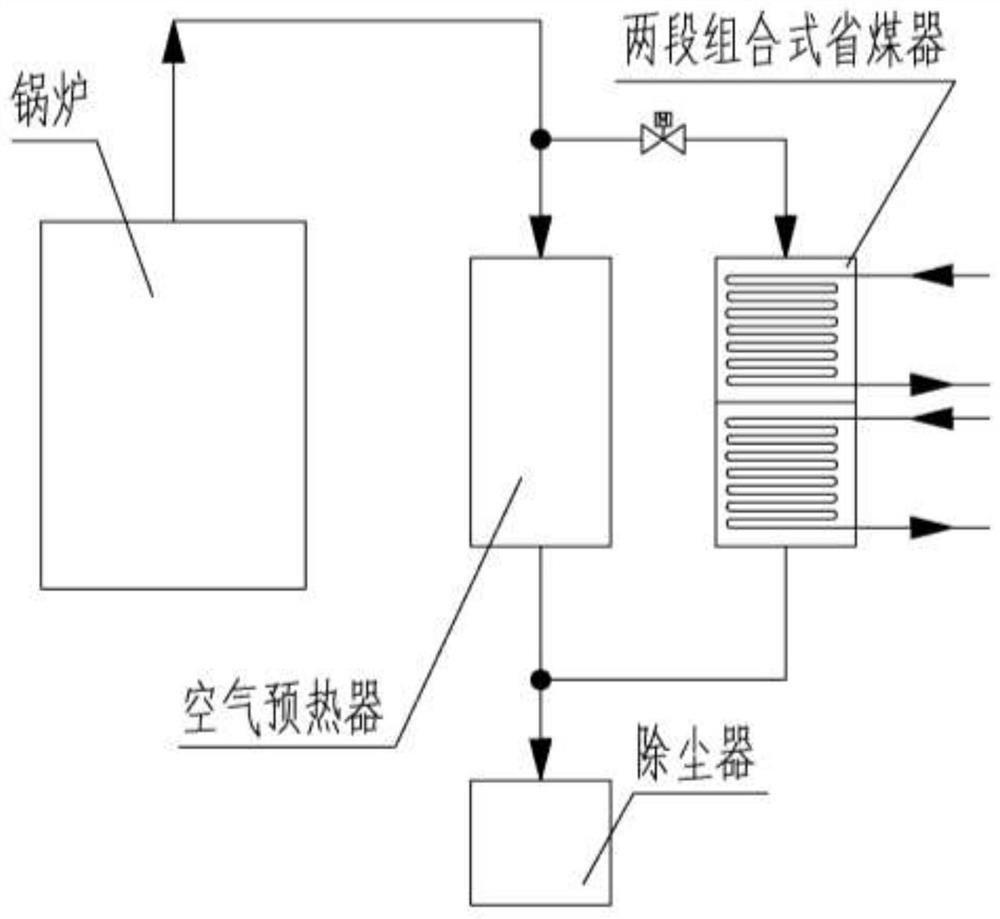

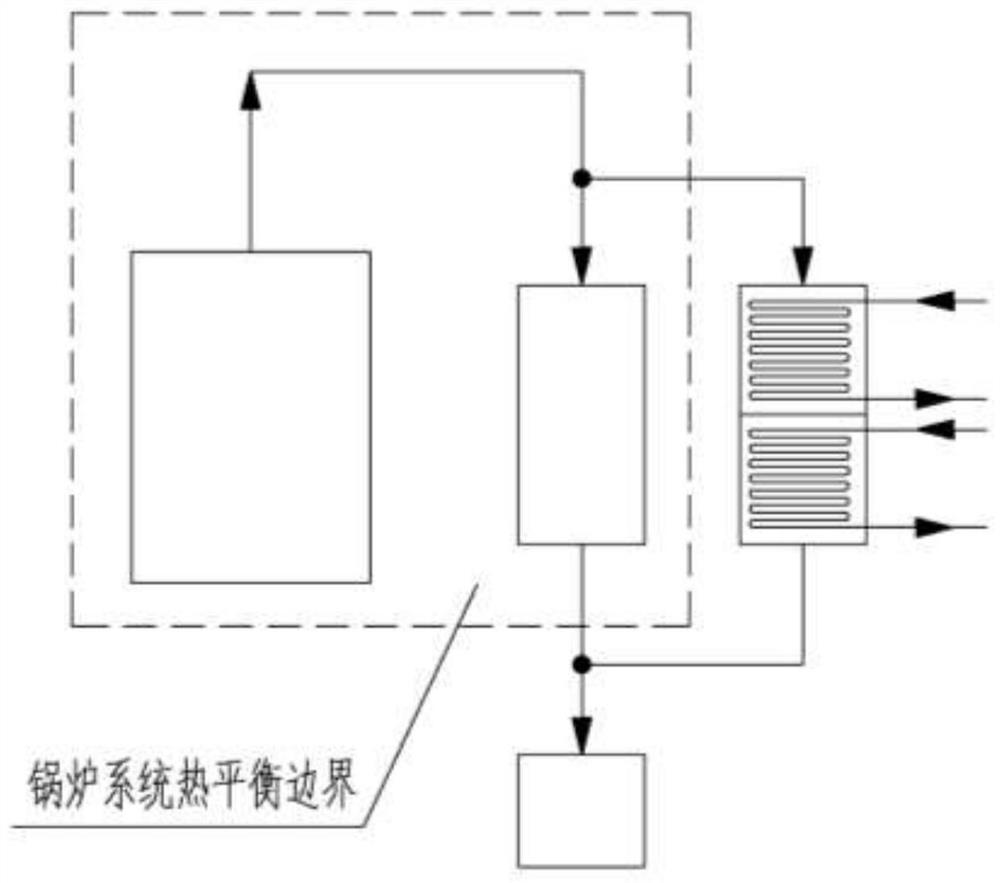

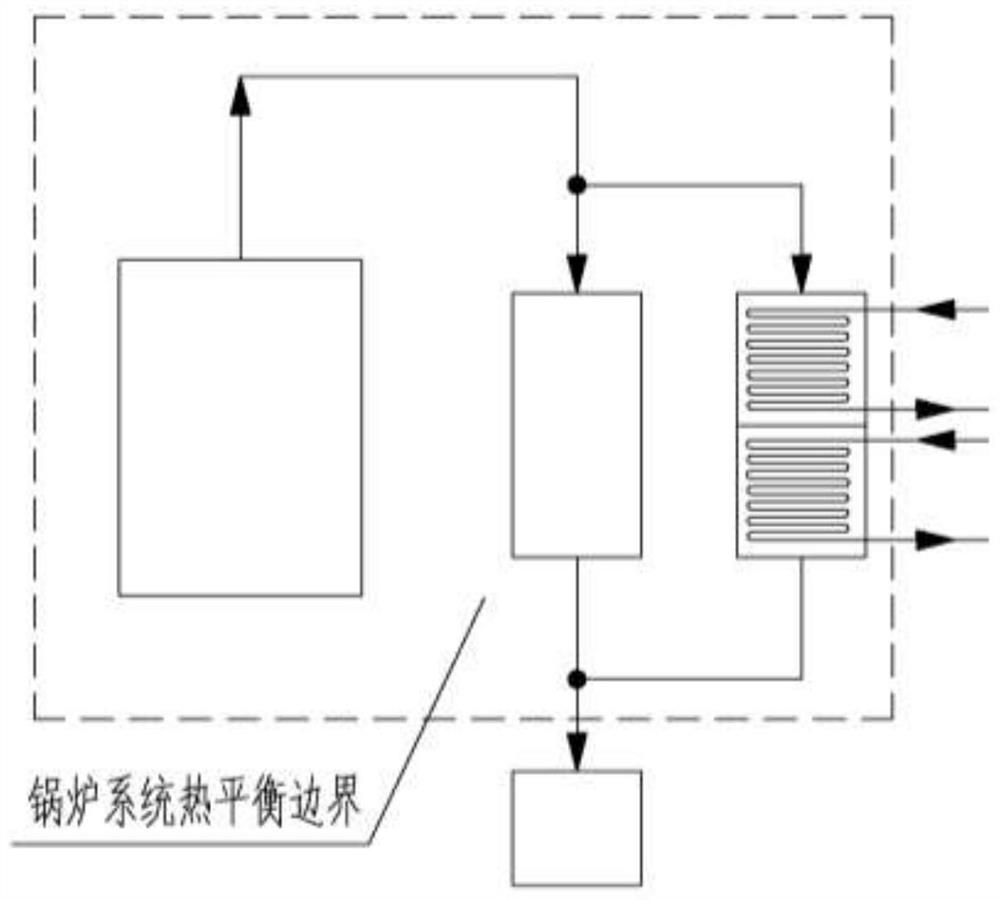

Method for evaluating influence of air preheater parallel-connection two-section combined economizer on boiler

An air preheater and economizer technology, applied in special data processing applications, computer-aided design, design optimization/simulation, etc., can solve the lack of scientific calculation basis, which is not conducive to the impact of evaluating the heat loss of economizer boilers And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0033] Example.

[0034]The No. 1 unit of a company is a 600MW unit boiler, which is a DG1900 / 25.4-Ⅱ1 supercritical parameter variable pressure DC Bunsen boiler produced by Dongfang Boiler (Group) Co., Ltd. Gas damper to adjust reheating steam temperature, solid slag discharge, all steel frame, full suspension structure, balanced ventilation, open-air layout, front and rear walls against combustion. Each furnace is equipped with 24 HT-NR3 swirl pulverized coal burners produced by Hitachi-Babcock (BHK), and is matched with 6 BBD4060 double-entry double-entry burners produced by Shanghai Heavy Machinery Factory Co., Ltd. out of the coal mill. It is designed to use lean coal from Shanxi Lu'an Mining Group Co., Ltd. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap