Horizontal well cross-layer fracturing feasibility evaluation method

An evaluation method and a feasible technology, which can be used in earth-moving drilling, wellbore/well components, and production fluids, etc., and can solve the problems of sand-passing, reducing and aggravating the conductivity of artificial fractures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Such as Figure 1-Figure 5 As shown, the horizontal well A is located in a block of the Ordos Basin, and the target layer is covered with a set of gas-bearing layers. The design adopts layer-crossing fracturing to improve the productivity of a single well and the production rate of geological reserves. The design steps are as follows:

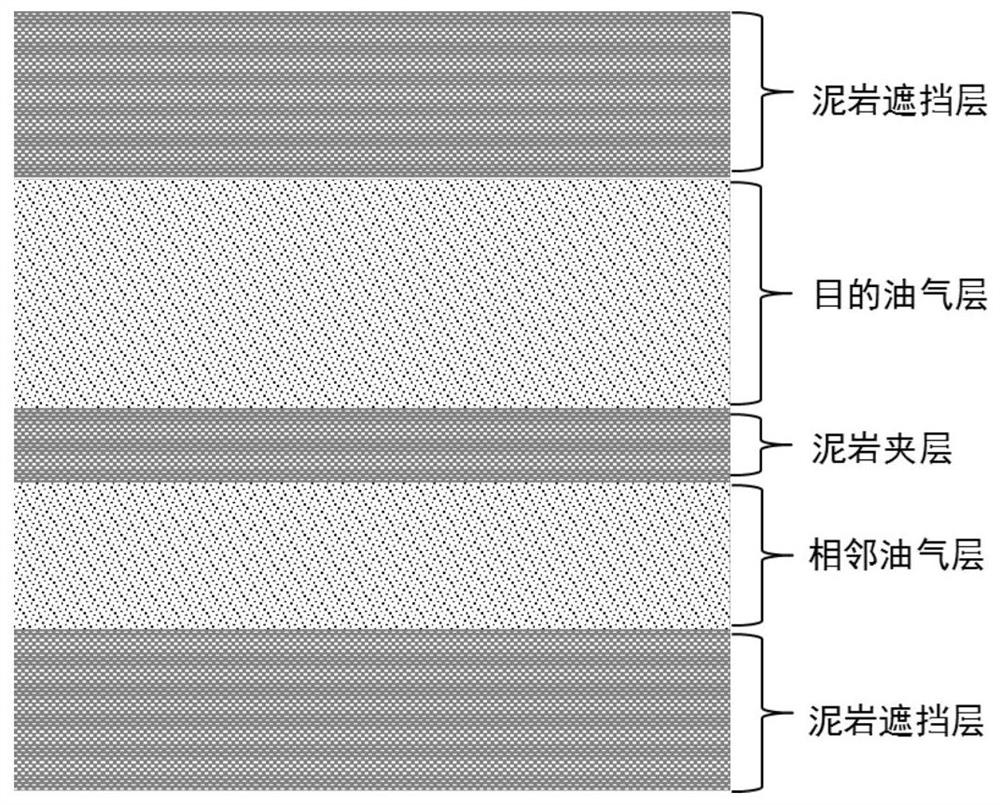

[0030] Step S1 establishes a geological model: as figure 1 As shown, the thickness of the target gas layer is 10.0m, and the thickness of the adjacent gas layer is 20m. Thickness 5m, closure stress 44MPa, Young's modulus 18GPa, Poisson's ratio 0.23;

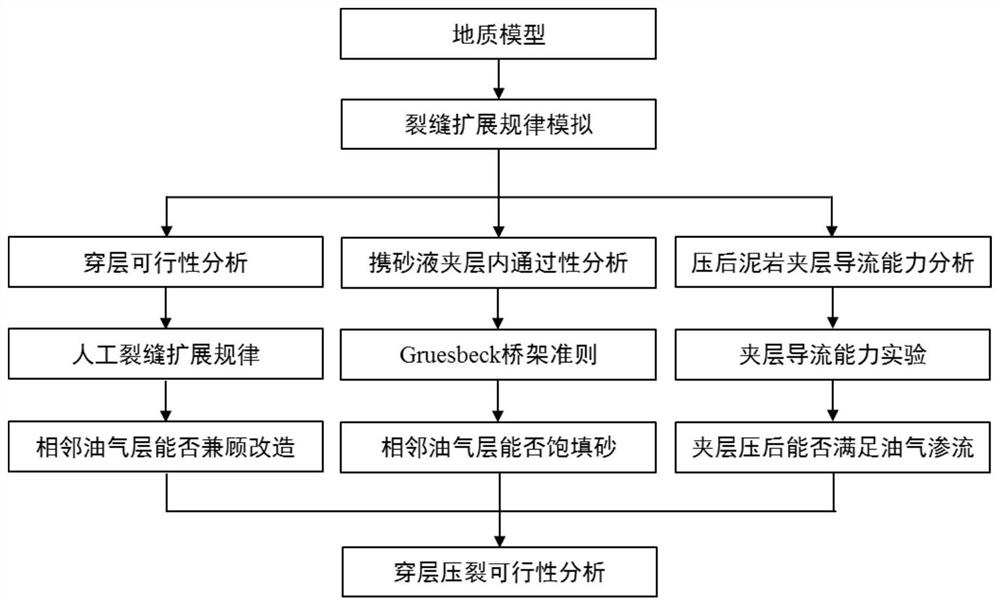

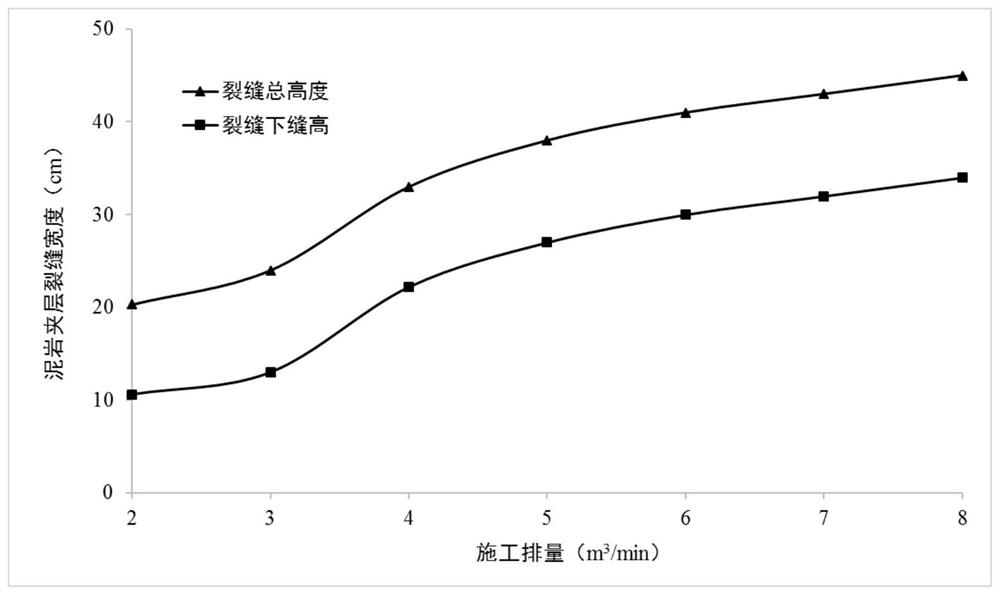

[0031] Step S2 Simulation of artificial fracture propagation law, based on the established geological model, using commercial software to simulate the relationship curves between different construction displacements, artificial fracture heights and inner fracture widths in mudstone interlayers, as shown in image 3 and Figure 4 shown;

[0032] Step S3 Feasibility evaluation of interlay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com