Chemical production safety assessment method based on improved fuzzy analytic hierarchy process

A fuzzy analytic hierarchy process, chemical production technology, applied in the field of chemical safety, can solve the problem of less research on human error direction, and achieve the effect of overcoming uncertainty and improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below.

[0032] The inventive method is specifically:

[0033] Step 1: Identify the indicator factors that affect the target.

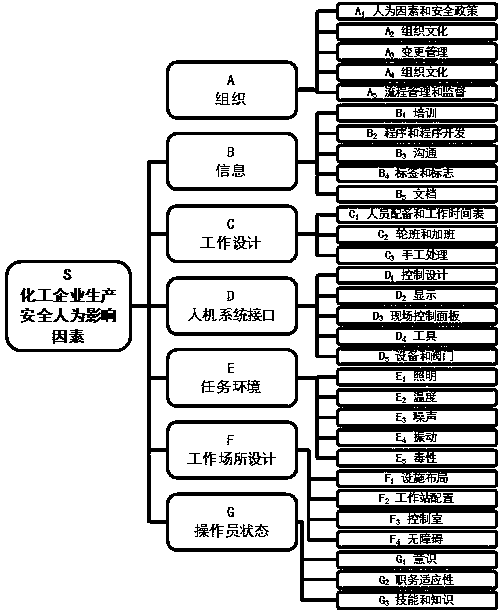

[0034] The safety of chemical plants should not only consider the safety of personnel themselves, but also consider the impact of production, systems, equipment, and the environment on people. Seven influencing factors (including organization, information, job design, human-machine system interface, task environment, workplace design, and operator characteristics) and 30 subfactors were identified.

[0035] Step 2: Establish a hierarchical structure system based on indicators.

[0036] According to the 7 factors and 30 sub-factors determined by human factors affecting the safety of chemical plants, a hierarchical structure is established. See the hierarchical structure diagram figure 1 .

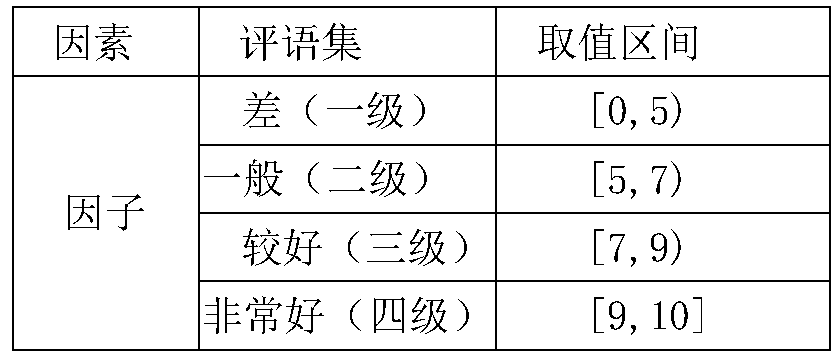

[0037] Step 3: Determine the comment set and standard cloud model of the indicator.

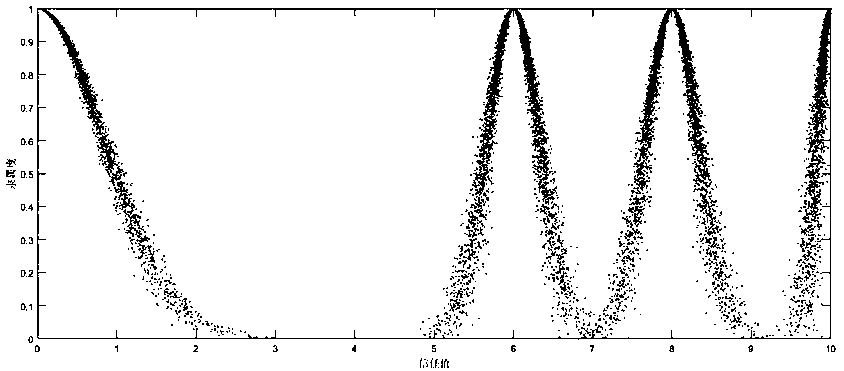

[0038] Step 3.1 Es...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com