Multifunctional cleaning scraper

A cleaning and multi-functional technology, which is applied to cleaning equipment, suction nozzles, vacuum cleaners, etc., can solve the problems of complicated structure of vacuum cleaners and squeegees, time-consuming and laborious disassembly and assembly, and storage space. Easy to use, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

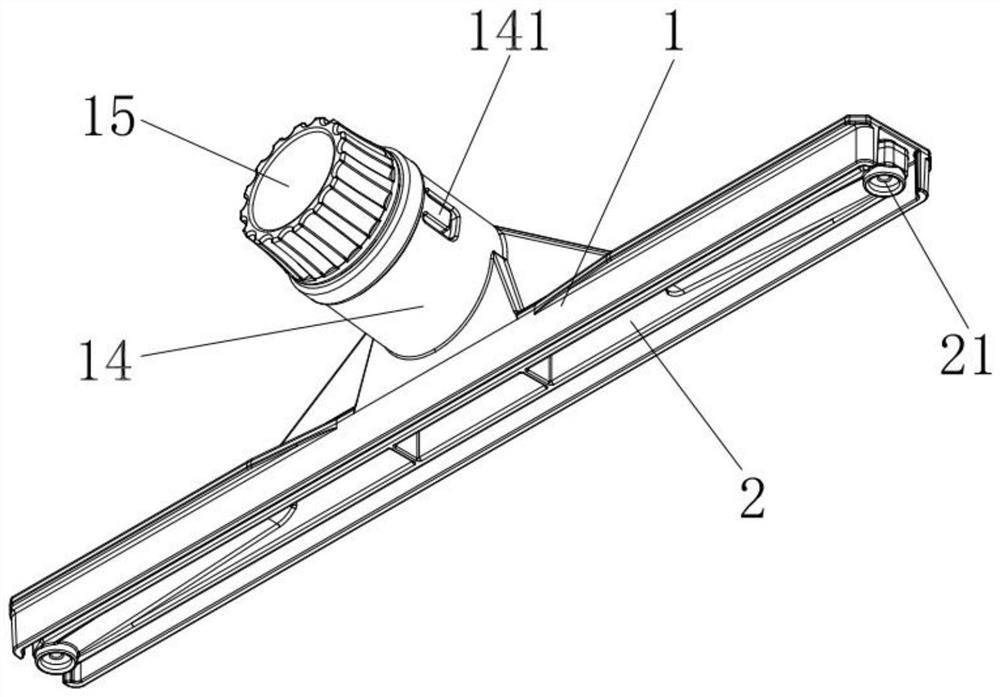

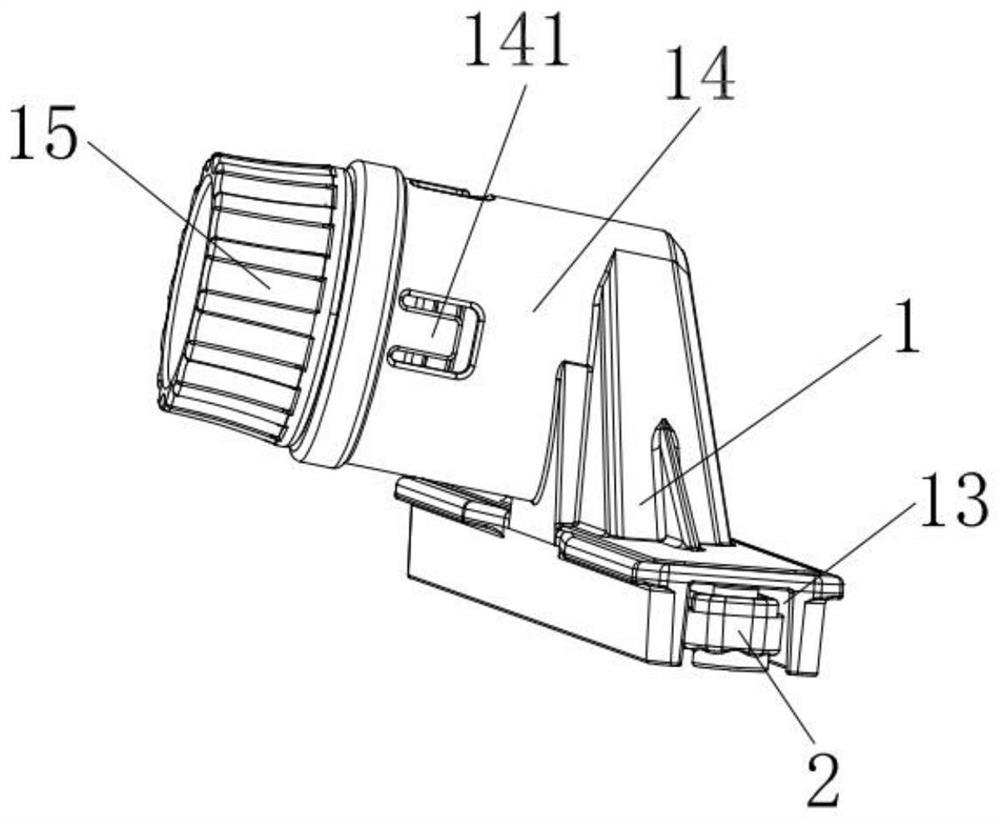

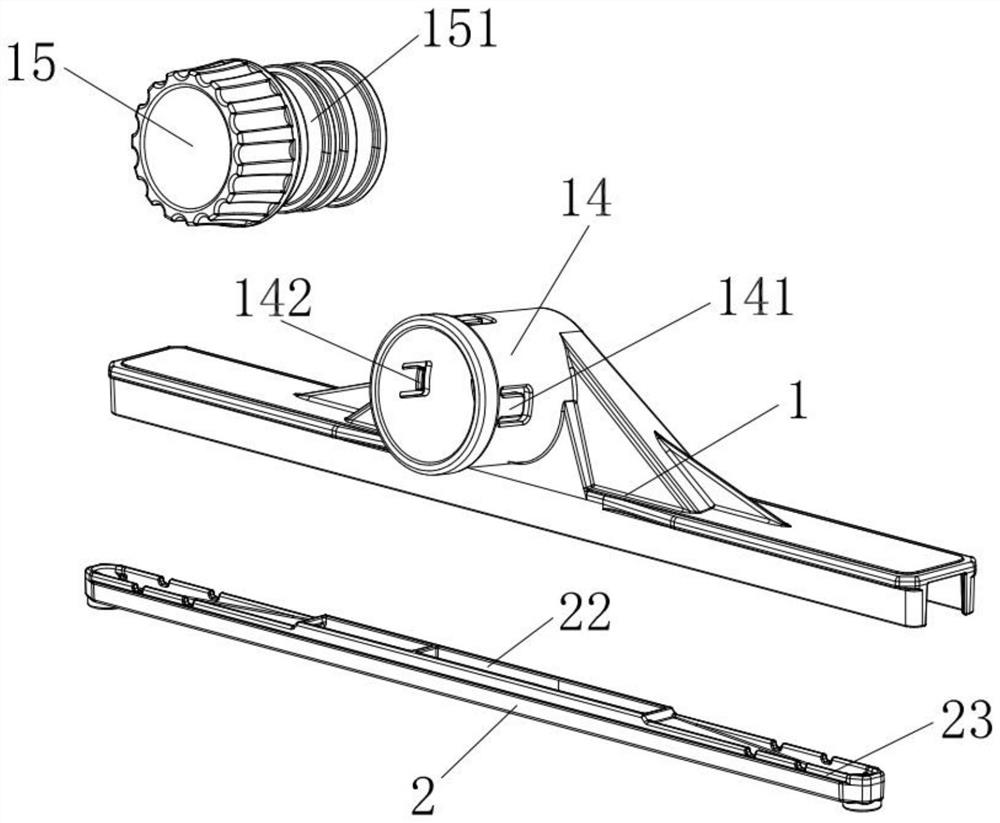

[0044] Such as Figure 1-7 As shown, a multi-functional cleaning grill for vacuum and water suction machines, including a grill seat 1, a fixed layer 2 and a vacuum brush strip 3;

[0045] An installation cavity 11 with an open bottom is provided in the grill seat 1, and the dust suction brush bar 3 is fixedly installed in the installation cavity 11 through the fixed bead 2, thereby forming a vacuum cleaner for the vacuum suction machine;

[0046] Both ends of the fixed bead 2 are symmetrically provided with mounting holes 21, and the inner side of the mounting cavity 11 is provided with a fixing hole 12 corresponding to the mounting hole 21. Through the mounting hole 21 and the fixing hole 12, the fixed bead 2 can be embedded and fixed with screws. In the installation cavity 11 , the vacuum brush bar 3 is pressed tightly in the installation cavity 11 , and a central through hole 22 is also penetratingly arranged on the fixed press bar 2 .

[0047] The dust-absorbing brush ba...

Embodiment 2

[0053] Such as Figure 1~4 and Figure 8-10 As shown in the figure, a multi-functional cleaning grill for vacuum and water suction machines includes a grill seat 1, a fixed bead 2 and a water-absorbing rubber strip 4;

[0054] An installation cavity 11 with an open bottom is provided in the grill seat 1, and the water-absorbing rubber strip 4 is fixedly installed in the installation cavity 11 through the fixed bead 2, thereby forming a squeegee for a dust-absorbing and water-absorbing machine;

[0055] Both ends of the fixed bead 2 are symmetrically provided with mounting holes 21, and the inner side of the mounting cavity 11 is provided with a fixing hole 12 corresponding to the mounting hole 21. Through the mounting hole 21 and the fixing hole 12, the fixed bead 2 can be embedded and fixed with screws. In the installation cavity 11 , the water-absorbing rubber strip 4 is pressed tightly in the installation cavity 11 , and a central through hole 22 is also penetratingly arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com