Disinfectant proportioning device

A disinfectant and box technology, applied in the field of quantitative proportioning of disinfectant volume, can solve the problems of cumbersome proportioning, achieve the effects of improving accuracy, reducing the risk of deterioration, and reducing the number of times of opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

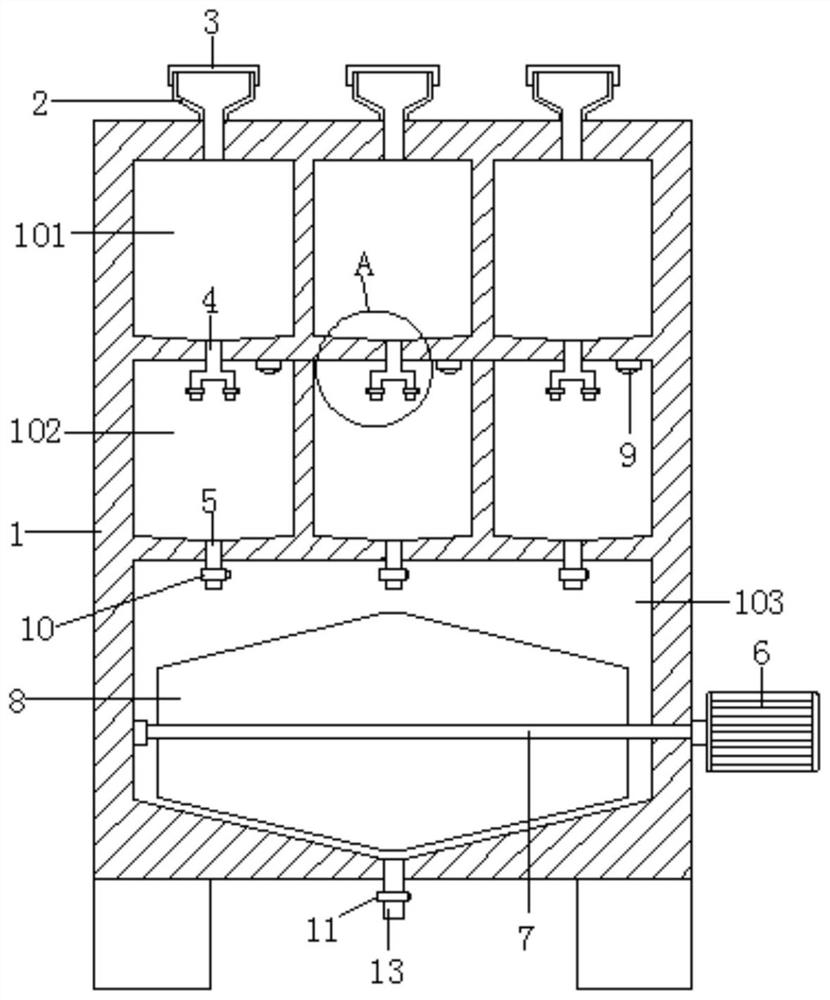

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

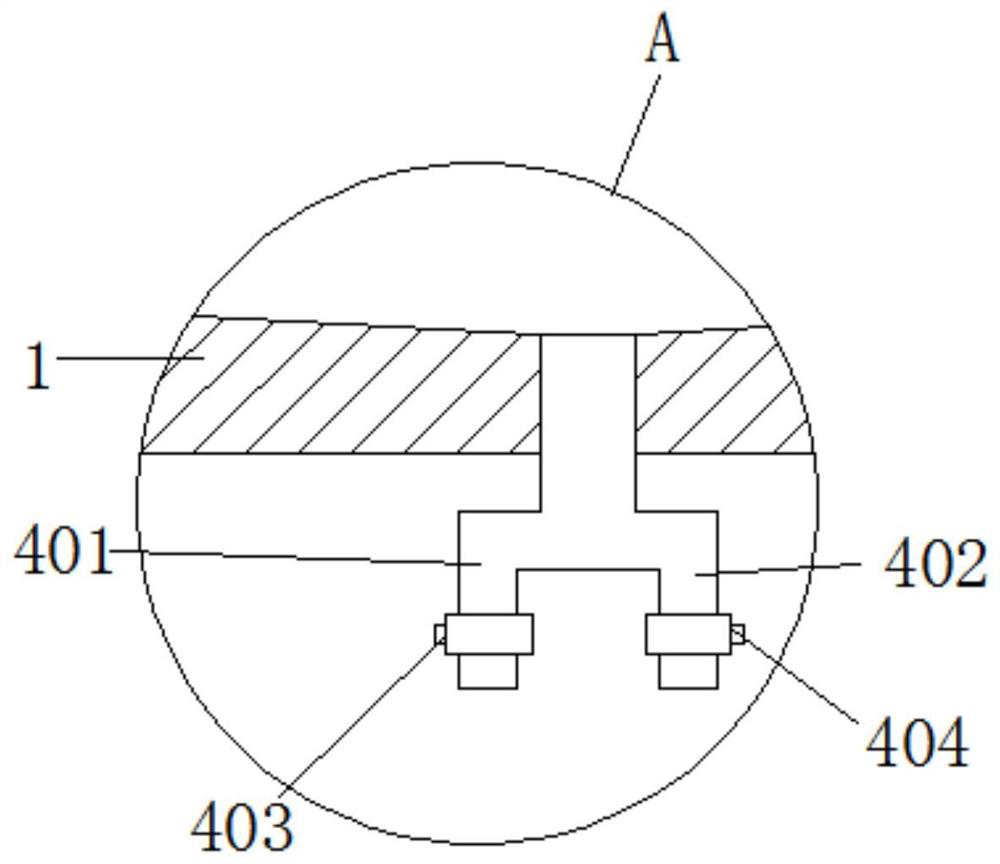

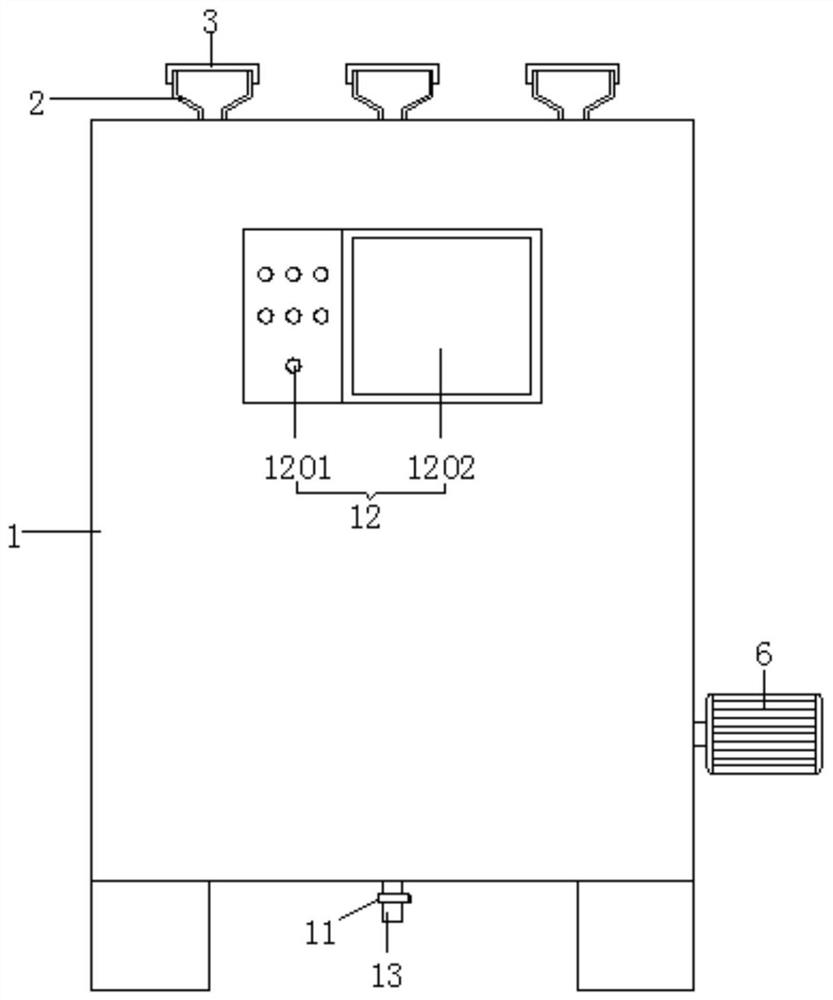

[0031] The present invention provides a technical solution: a disinfectant proportioning device, comprising a box body 1, the inner cavity of the box body 1 is provided with a storage chamber 101 on the first floor, a proportioning chamber 102 on the second floor and In the mixing chamber 103 of the third layer, the top of the box body 1 is provided with a feed port 2 communicating with each group of storage chambers 101, the top of the feed port 2 is screwed with a sealing cover 3, and the bottom of the storage chamber 101 is provided with a connecting The upper connecting pipe 4 of the proportioning chamber 102 directly below, the bottom of the proportioning chamber 102 is provided with the lower communicating pipe 5 communicating with the mixing chamber 103, the right side w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com