Automatic artificial board drilling device and working method thereof

A drilling device and wood-based panel technology, applied to fixed drilling machines, transportation and packaging, conveyor objects, etc., can solve the problems of low transportation efficiency, low work efficiency, inflexibility, etc., achieve simple design structure and improve work efficiency , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

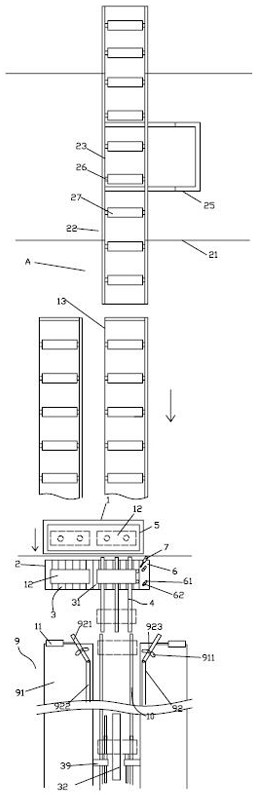

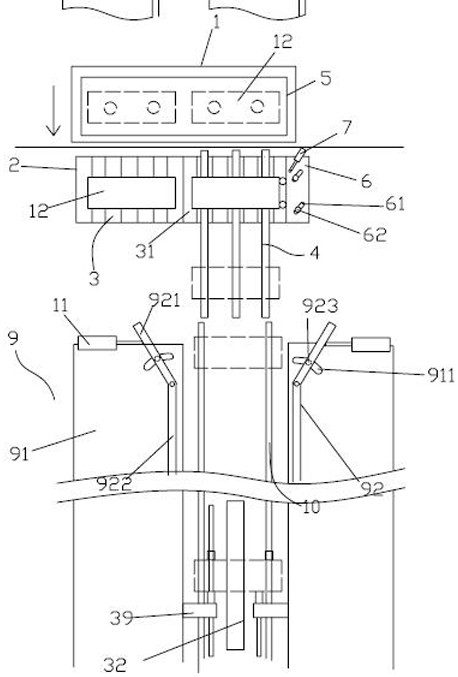

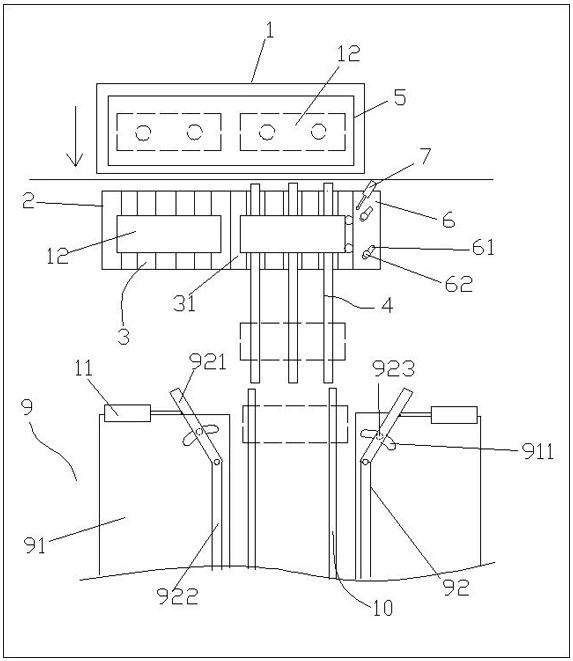

[0028] Such as Figure 1~9As shown, the wood-based panel automatic drilling device includes a cart loading mechanism A, and the cart loading mechanism includes two parallel stacking racks 13, and the wood-based panel is transported to the stepping lift platform 1 through the two stacking racks. There is a lifting frame 2 in front of the lifting platform, and a roller transmission mechanism 3 is arranged on the lifting frame, and a suction cup mechanism for sucking the artificial board and placing the artificial panel on the roller transmission mechanism is arranged above the stepping lifting platform 5. The roller transmission mechanism includes a plurality of rollers 31 arranged at intervals along the left and right length direction of the lifting frame, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com