Device for packaging rear end of disc-shape chip

A chip and disk-shaped technology, which is applied in the field of chip back-end packaging equipment, can solve the problems of low production efficiency, crushed tape chips, and high labor costs, so as to achieve uniform tape attachment positions, improve work efficiency, and reduce labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. The relevant components in the invention are not drawn according to the number, shape and size of the components in actual implementation. The type, quantity and proportion of each component in actual implementation can be changed arbitrarily, and the layout of the components may also be changed for complex.

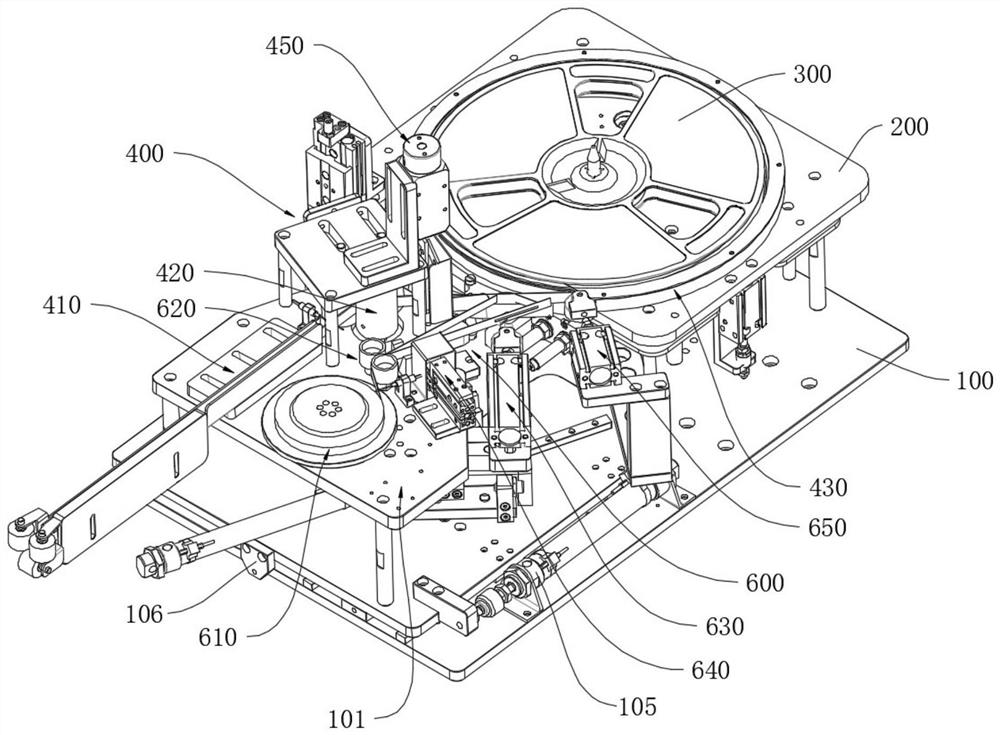

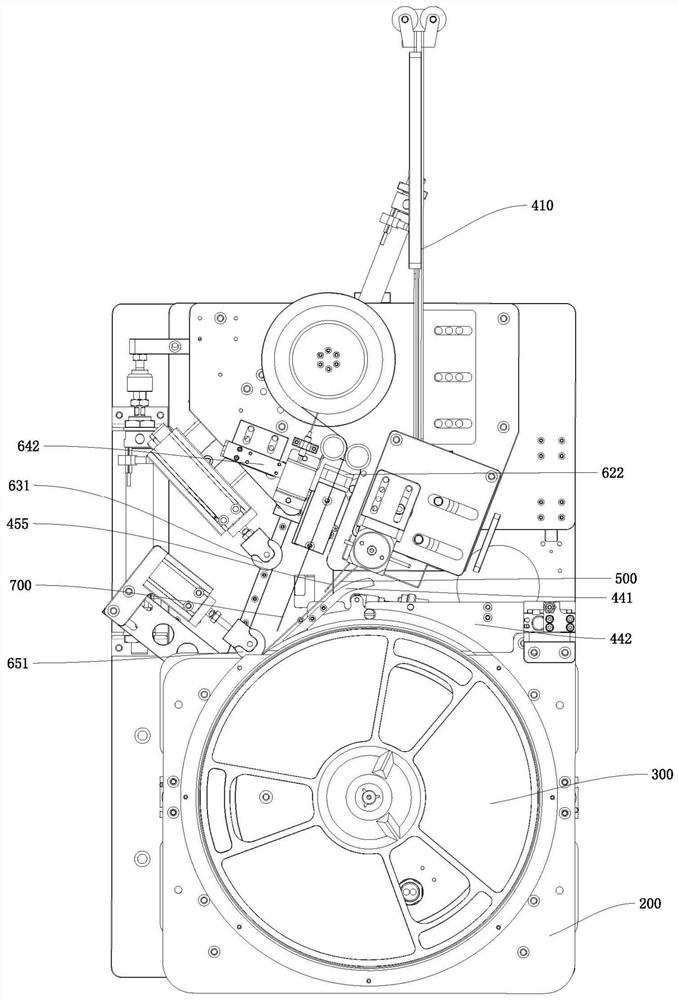

[0052] See Figure 1 to Figure 11 , a back-end packaging device for disk-shaped chips according to the present invention, comprising:

[0053] A support platform 200 for placing disc-shaped chips 300;

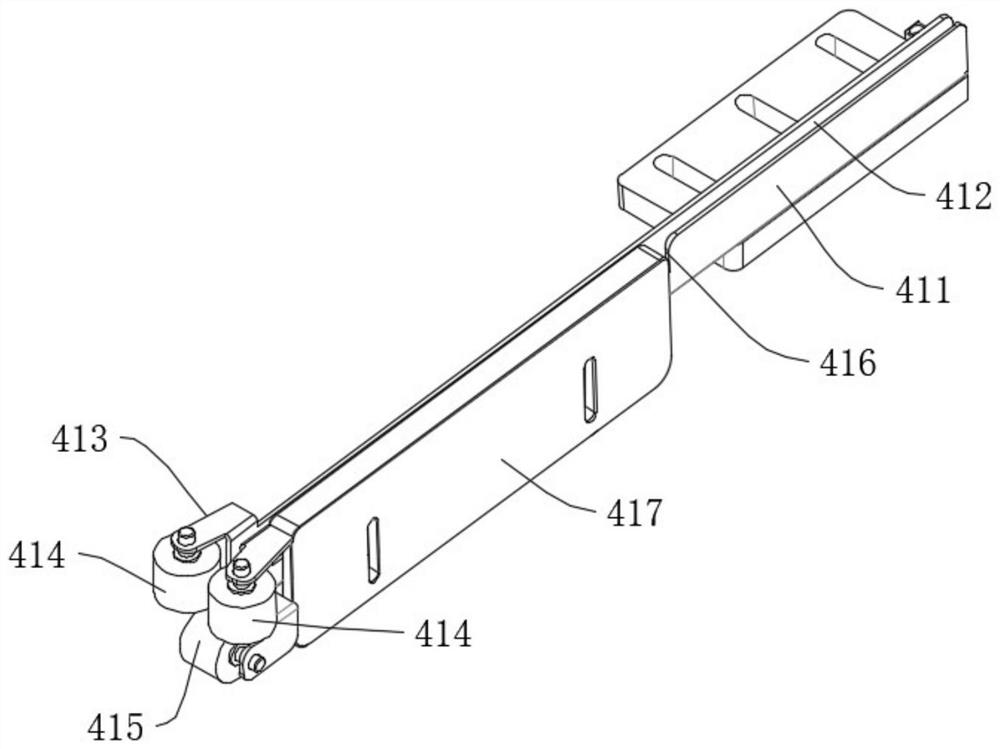

[0054] The protective tape winding unit 400 is used to feed the protective tape 500 and wind the protective tape 500 on the disk-shaped chip 300 placed on the support platform;

[0055] The adhesive tape sticking unit 600 is used for pasting the adhesive tape 700 on the protective tape 500 to seal the interface of the prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com