Storage robot control method and device, equipment and readable storage medium

A control method and robot technology, applied in the fields of equipment, readable storage media, devices, and storage robot control methods, can solve the problem of low safety of storage robots, reduce the probability of cargo damage and shelf dumping, avoid danger, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

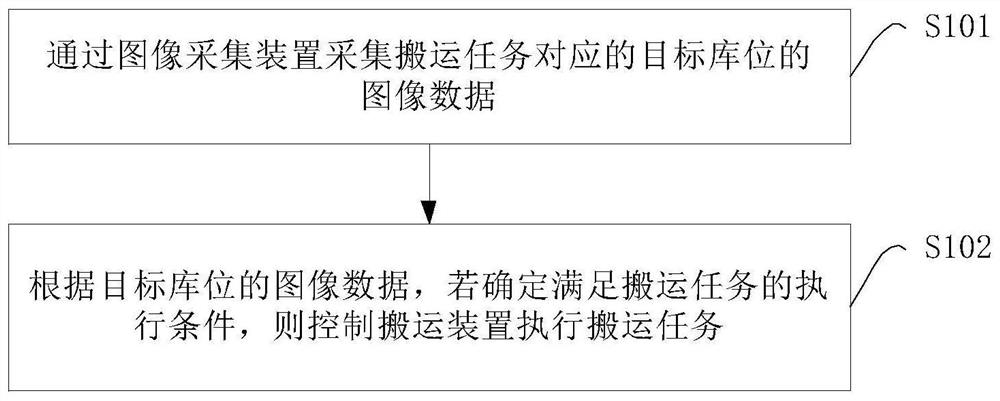

[0074] figure 1 It is a flow chart of the control method of the storage robot provided by Embodiment 1 of the present invention. The method in this embodiment is applied to a warehouse robot. In other embodiments, the method can also be applied to other devices, and this embodiment uses a warehouse robot as an example for schematic illustration. The execution subject of the method in this embodiment may be a processor for controlling the storage robot to perform the handling task, for example, it may be a processor of a terminal device loaded on the storage robot. like figure 1 As shown, the specific steps of the method are as follows:

[0075] Step S101 , collecting image data of a target warehouse location corresponding to a transport task through an image collection device.

[0076] Wherein, the handling task includes the information of the corresponding target warehouse location, task type, and other information required for performing the current task. Wherein, the t...

Embodiment 2

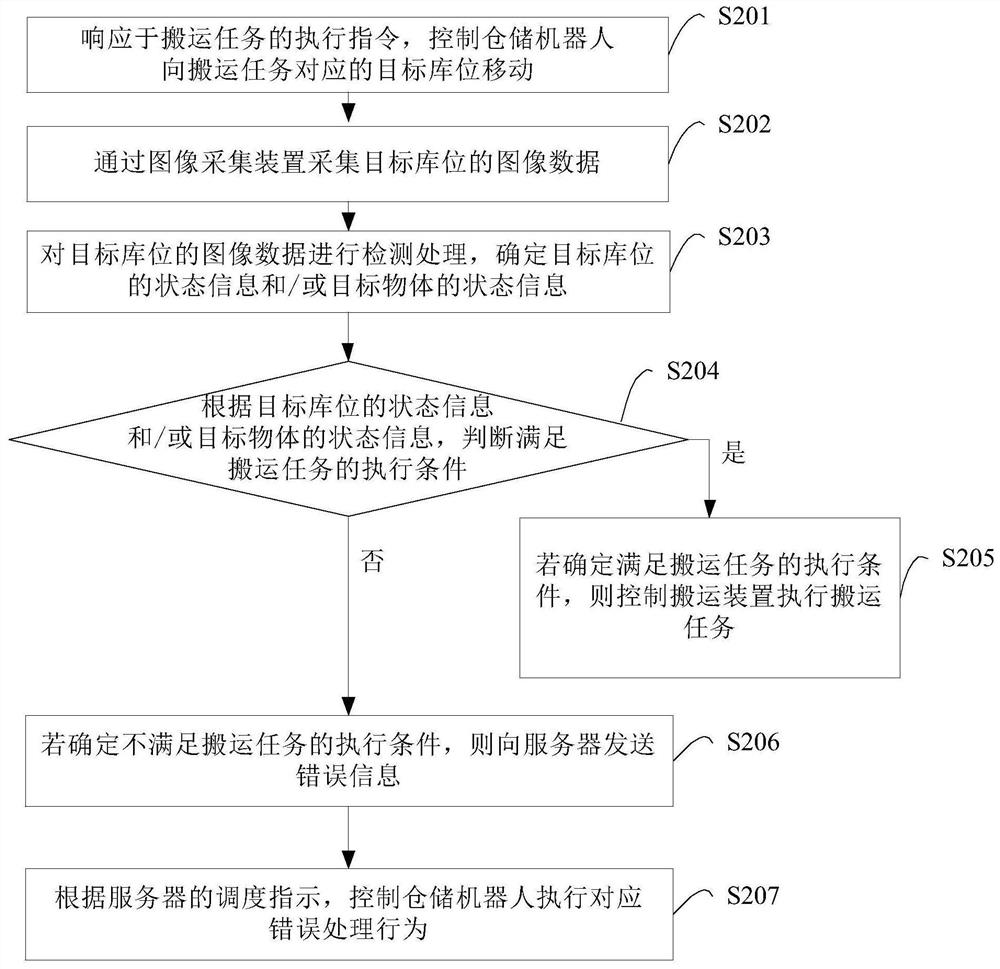

[0090] figure 2 It is a flow chart of the control method of the storage robot provided by the second embodiment of the present invention. On the basis of the first embodiment above, in this embodiment, according to the image data of the target location, if it is determined that the execution conditions of the transportation task are met, then the transportation device is controlled to perform the transportation task, including: detecting the image data of the target location Processing, determining the status information of the target storage location and / or the target object; according to the status information of the target storage location and / or the target object, if it is determined that the execution conditions of the transportation task are met, then controlling the transportation device to perform the transportation task. Further, according to the image data of the target location, if it is determined that the execution condition of the transport task is not satisfied...

Embodiment 3

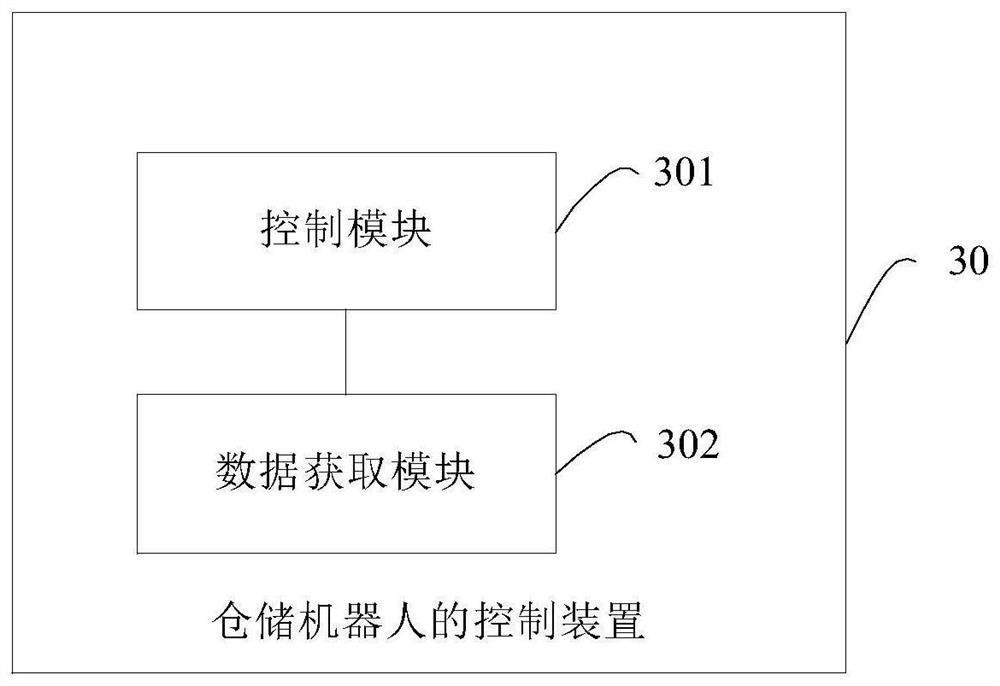

[0171] image 3 It is a schematic structural diagram of a control device for a storage robot provided in Embodiment 3 of the present invention. The control device of the storage robot provided in the embodiment of the present invention can execute the processing procedure provided in the embodiment of the control method of the storage robot. like image 3 As shown, the control device 30 of the storage robot includes: a control module 301 and a data acquisition module 302 .

[0172] Specifically, the control module 301 is used to control the storage robot to move to the target storage location of the handling task in response to the execution instruction of the handling task;

[0173] The data acquisition module 302 is used to collect the image data of the target warehouse location through the image acquisition device;

[0174] The control module 301 is further configured to: according to the image data of the target location, if it is determined that the execution condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com