A scraper conveyor body automatic straightening device and method based on spatial position information capture

A technology of spatial position information and scraper conveyor, applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve problems such as large errors, achieve increased accuracy, rapid response to body straightening, and independent analysis Body straightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

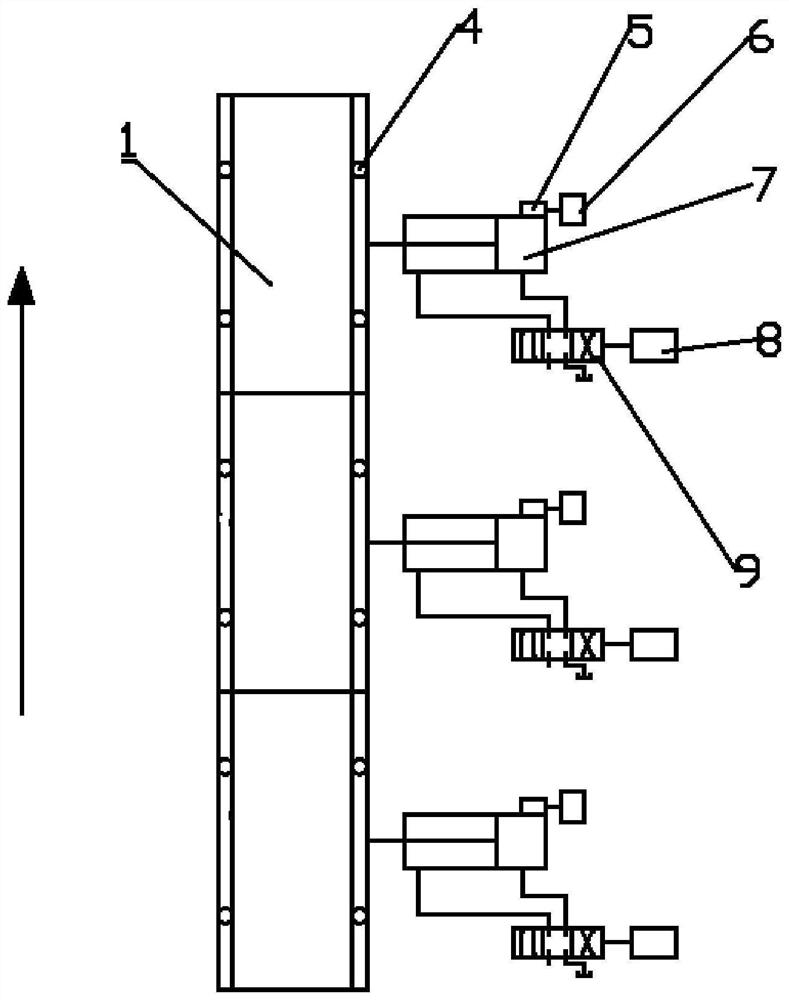

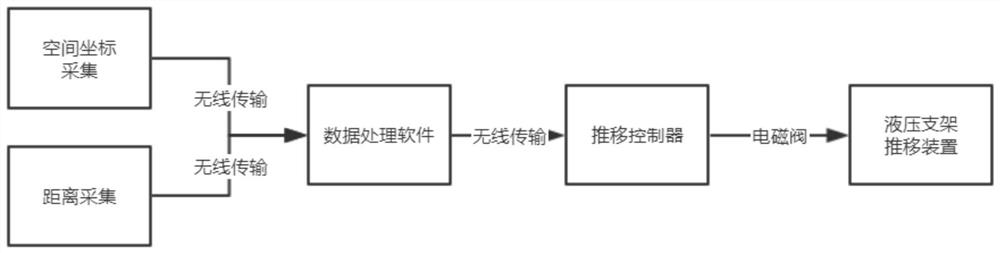

[0041] Such as figure 1As shown, this embodiment provides an automatic straightening device for a scraper conveyor body based on spatial position information capture, including a slot 1 in the middle of the scraper conveyor, a spatial position information collection device, a data transmission device, and a straightening action actuator ,in:

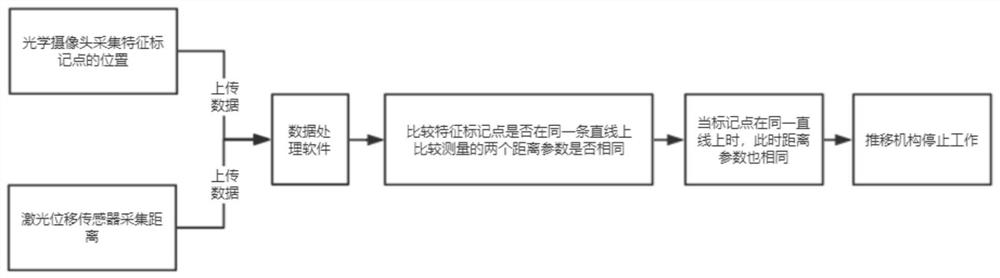

[0042] The straightening action actuator is installed at the same distance on one side of the middle groove of the scraper conveyor, and the straightening action actuator is a hydraulic pushing device 7, and the hydraulic pushing device 7 is connected to the pushing ear on the middle groove of the scraper conveyor through the connecting head. connected with each other, and then straighten the scraper conveyor through the back and forth movement of the hydraulic pushing device. All laser displacement sensors 5 are installed on the same horizontal plane as the hydraulic pushing device 7 and the center line of the side steel of the scraper ...

Embodiment 2

[0055] An automatic straightening device of a scraper conveyor body based on spatial position information capture, the structure is as described in Embodiment 1, the difference is that the characteristic position marker is installed in the groove on the middle groove of the scraper conveyor through the mounting seat The top surface of the side steel is 1 / 4 away from both ends, such as Figure 4 shown.

Embodiment 3

[0057] An automatic straightening device of a scraper conveyor body based on spatial position information capture, the structure is as described in Embodiment 2, the difference is that the mounting seat includes an aluminum sheet 2 and a thin steel plate 3, and the structure of the mounting seat is as follows Figure 7 As shown, the aluminum sheet 2 and the thin steel plate 3 are fixedly connected by bolts. The aluminum sheet 2 and the thin steel plate 3 are circular plates with the same cross section. There is a circular through hole through the thin steel plate, and the structure of the thin steel plate 3 is as follows Figure 8 As shown, a circular through hole of the same size is provided in the middle of the aluminum sheet 2, a characteristic position marker is welded in the circular through hole of the aluminum sheet 2, a magnet is placed in the circular groove of the thin steel plate 3, and the thin steel plate 3 passes through the magnet. Installed on the side steel of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com