Sound insulation mortar, sound insulation floor structure and preparation method of sound insulation mortar

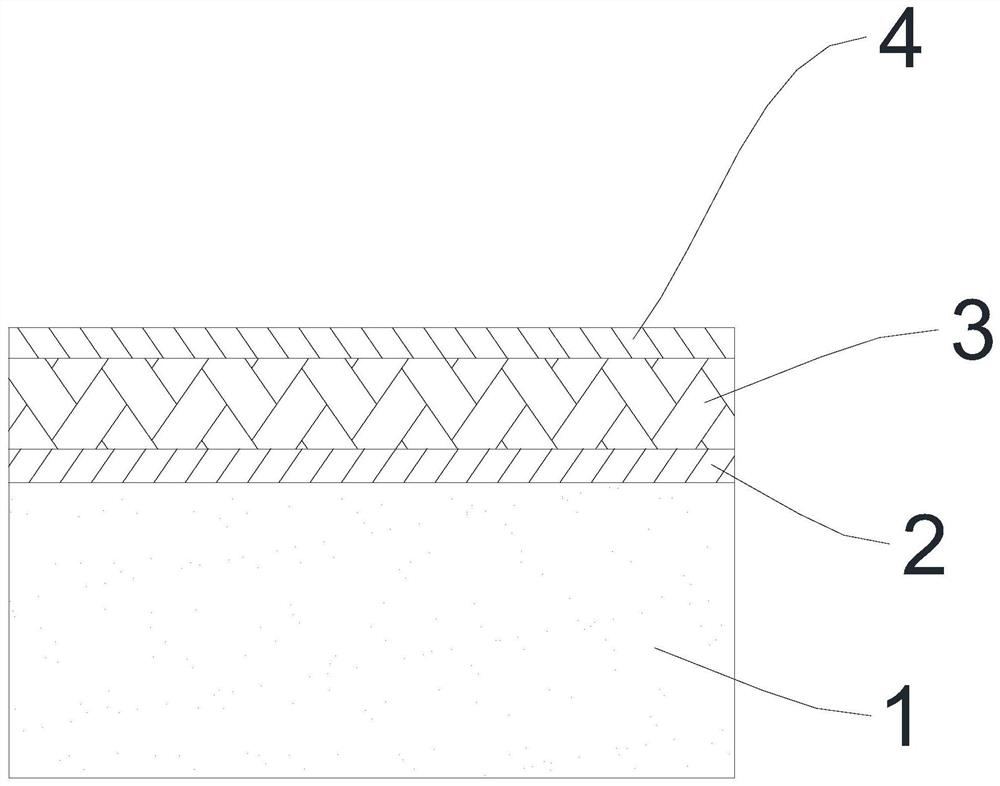

A technology of sound insulation and mortar, which is applied in the direction of floors, clay preparation devices, chemical instruments and methods, etc., can solve the problems of the effective height of the house becoming shorter, the thickness of the sound insulation floor is thick, and occupying the space of the house, so as to achieve good sound insulation effect, High effective height and space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

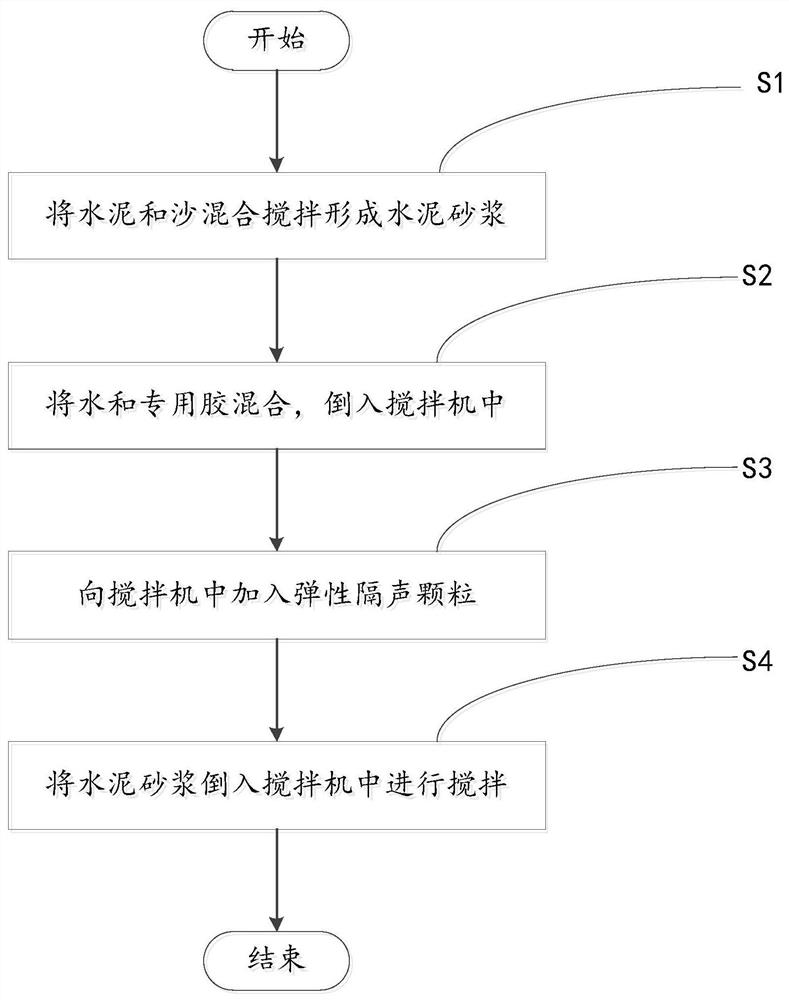

[0038] This embodiment provides a kind of sound insulation mortar, is made up of the following raw materials by weight percentage:

[0039] Cement: 20%;

[0040] Elastic sound insulation particles: 20%;

[0041] Sand: 25%;

[0042] Special glue: 15%;

[0043] Water: 20%.

[0044] The sound insulation mortar prepared according to this ratio is used for the impact sound test experiment. The impact sound test experiment needs to be carried out in the sound emitting room and the receiving room. Two rooms, the room on the upper floor is the sounding room, and the room on the lower floor is the receiving room. Spread 10mm thick soundproofing mortar on the floor of the sounding room to form a 10mm thick soundproofing mortar layer. The impactor is placed on the sound-proof mortar layer, and the microphone is placed on the floor of the receiving room. According to the records in "GB / T 19889.7-2005 Acoustic Building and Building Component Sound Insulation Measurement Part 7: On-si...

Embodiment 2

[0050] This embodiment provides another kind of sound insulation mortar, which is made up of the following raw materials by weight percentage:

[0051] Cement: 13%;

[0052] Elastic sound insulation particles: 28%;

[0053] Sand: 26%;

[0054] Special glue: 8%;

[0055] Water: 25%.

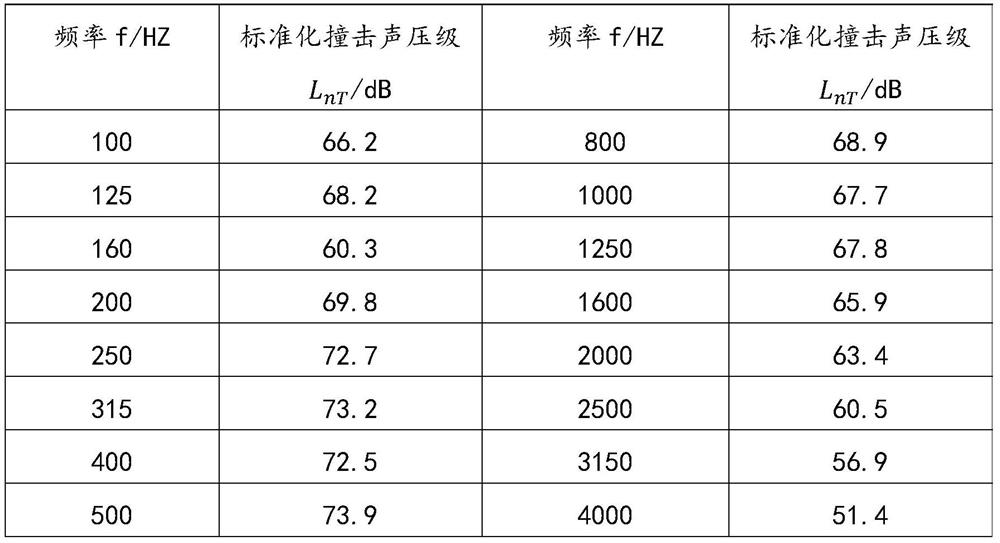

[0056] The sound insulation mortar of this embodiment was used to conduct an impact sound test experiment, and this experiment was recorded as Experiment 2. The experimental principle and experimental process of Experiment 2 are the same as those of Experiment 1. Normalized impact sound pressure level L in experiment 2 nT The relationship between it and the impact sound frequency f is shown in the table below.

[0057] Table 2 Relationship between normalized impact sound pressure level and impact sound frequency in Experiment 2

[0058]

[0059]

[0060] According to Table 2, it can be concluded that the sound insulation mortar layer provided by this embodiment is made into a 10mm sou...

Embodiment 3

[0062] The present embodiment provides the third kind of sound insulation mortar, which is made up of the following raw materials by weight percentage:

[0063] Cement: 13%;

[0064] Elastic sound insulation particles: 30%;

[0065] Sand: 25%;

[0066] Special glue: 12%;

[0067] Water: 20%.

[0068] The sound insulation mortar of this embodiment was used to carry out the impact sound test experiment, and this experiment was recorded as experiment 3. The experimental principle and experimental process of Experiment 3 are the same as those of Experiment 1. Normalized impact sound pressure level L in experiment 3 nT The relationship between it and the impact sound frequency f is shown in the table below.

[0069] Table 3 Relationship between normalized impact sound pressure level and impact sound frequency in Experiment 3

[0070]

[0071]

[0072] According to Table 3, it can be concluded that the sound insulation mortar layer provided by this embodiment is made in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap