Single-electrode-stem atmosphere-controllable electroslag furnace for efficient production

An electrode rod and single electrode technology, which is applied in the field of electroslag furnace, can solve the problems such as the decline of the quality level of the steel ingot and the difficulty in controlling the temperature, and achieve the effect of prolonging the service life, constant temperature and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

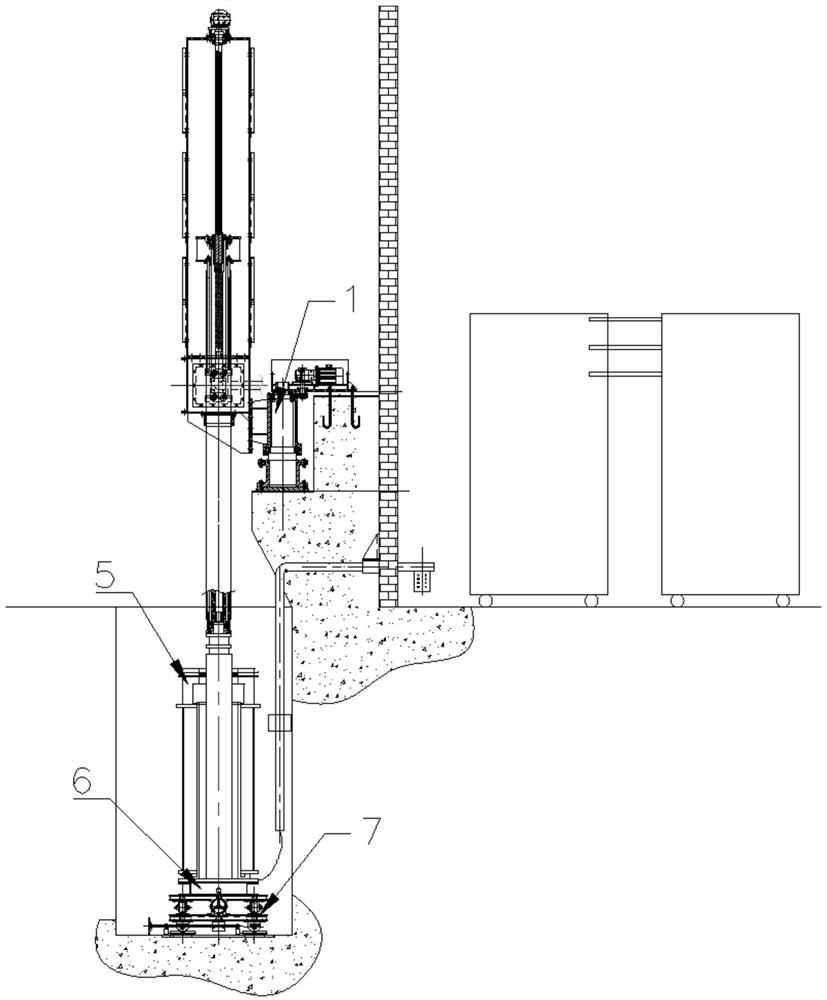

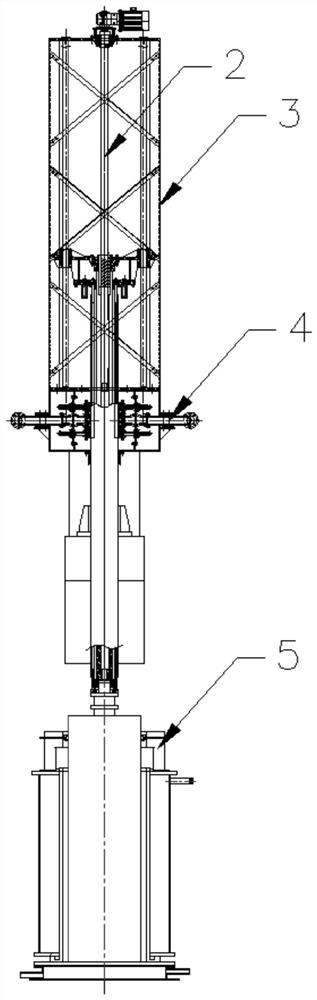

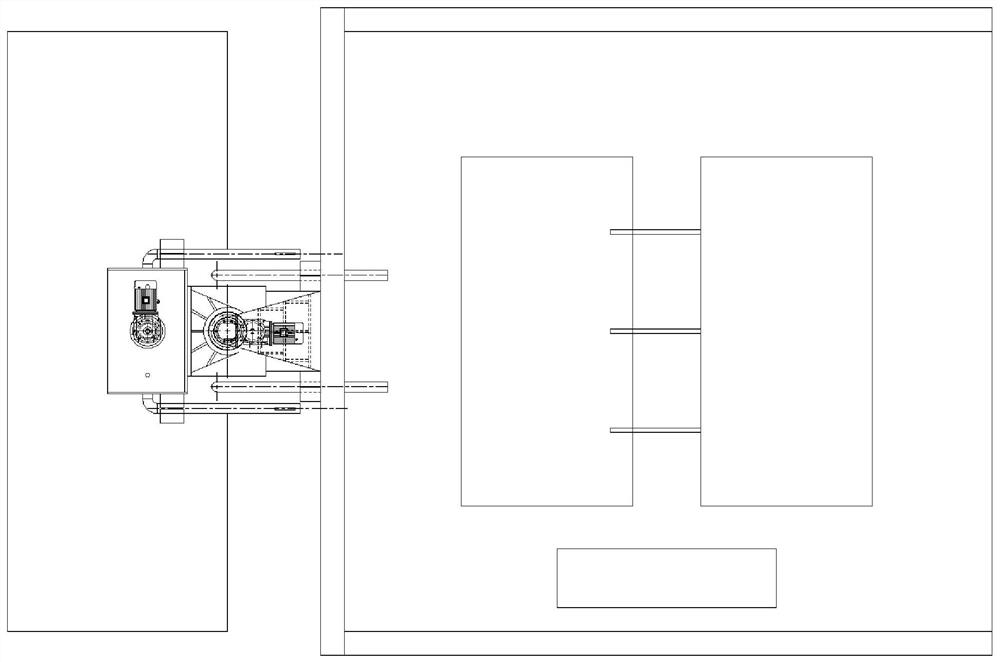

[0065] A single electrode rod controlled atmosphere electroslag furnace for efficient production, such as Figure 1-Figure 3 As shown, it includes an electrode rod rotating device 1, the electrode rod rotating device 1 is connected with an electrode rod lifting device 2, and the electrode rod lifting device 2 is covered with an electrode rod lifting frame 3, and the electrode rod lifting device 2 is equipped with an electric A brush device 4, a crystallizer is installed under the electrode rod lifting device 2, the upper end of the crystallizer is provided with an atmosphere protection cover 5, and the bottom of the crystallizer is connected with a bottom water tank 6 and a double-layer trolley adjustment device in sequence from top to bottom 7.

Embodiment 2

[0067] On the basis of Example 1, such as Figure 4-Figure 7 As shown, the electrode rod elevating device a2 includes a drive motor, the drive motor a1 is connected with a lead screw a2 arranged in the vertical direction, the top end of the lead screw a2 is sleeved with a bearing support a3, the lead screw The bottom end of the screw a2 is connected with an electrode rod a4, and a thrust bearing is connected between the bearing support a3 and the lead screw a2, and the electrode rod a4 includes an inner ring rod a13, a middle ring rod a14 and an outer The ring rod a15, the bottom end of the electrode rod a4 is connected with a pneumatic chuck a5, the pneumatic chuck a5 is installed between the inner ring rod a13 and the outer ring rod a15, and the pneumatic chuck a5 is connected with a consumable electrode a6 , both sides of the bearing support a3 are connected with an upper horizontal strut a7, and the upper horizontal strut a7 is connected with a guide rod a8 parallel to the...

Embodiment 3

[0070] On the basis of Example 1, such as Figure 8-Figure 11 As shown, the electrode rod lifting frame 3 includes a top frame plate b1 at the upper end and a bottom frame plate b2 at the bottom end, and a side plate b3 is connected between the top frame plate b1 and the bottom frame plate b2, and the side plate B3 is connected with supporting angle steel b4, said supporting angle steel b4 is set as a group of two intersecting ones, and there are at least three groups arranged from top to bottom, and the side plate b3 is equipped with lifting rail b5 arranged in the vertical direction , the cooling and cleaning device is installed on the lifting rail b5, the cooling and cleaning device includes a support frame b6 connected with the lifting rail b5, and the support frame b6 is installed around the outside of the side plate b3 and the supporting angle b4, so A water diversion plate b7 is installed on one side of the support angle b4 on the support frame b6, and a plurality of wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com