Partition surface treatment device and treatment method for nut parts

A surface treatment device and nut technology, applied in the direction of electrolysis components, electrolysis process, etc., can solve problems such as the reduction of thread screwing performance, and achieve the effects of increased processing efficiency, simple device structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

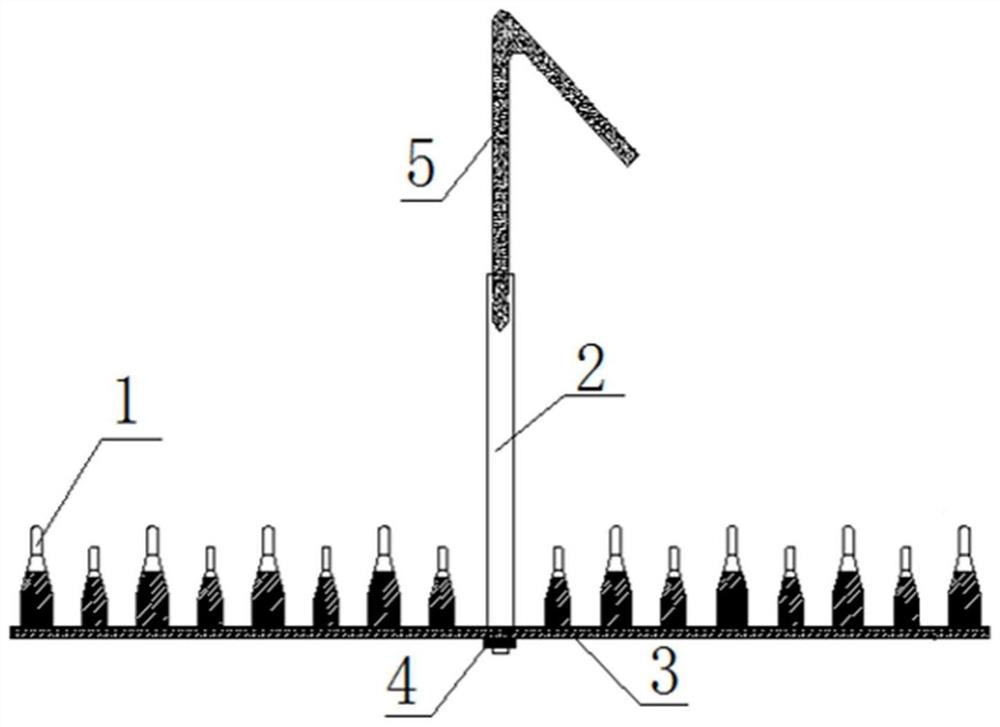

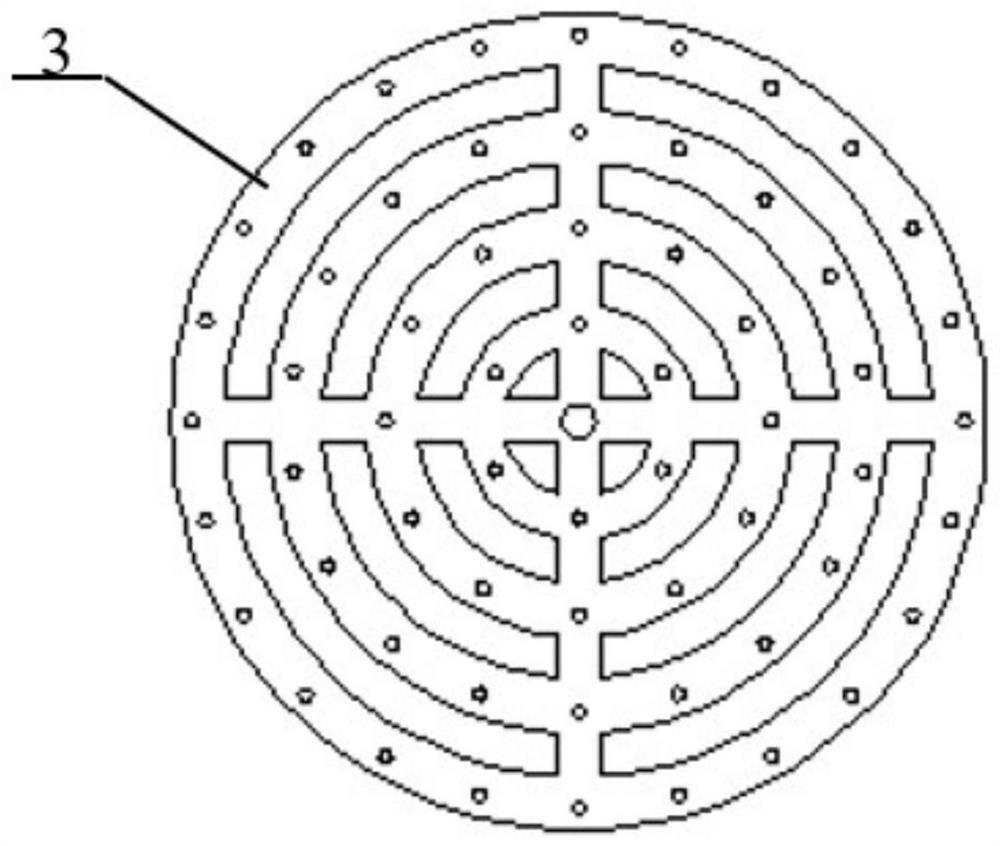

[0038] A partition surface treatment device for nut parts, such as figure 1 As shown, the parts that do not need to be conductive (the parts that do not touch each other) on the clamping head 1, the hanging rod 2 and the fixed plate 3 are insulated and coated with electroplating glue, and the device is assembled after the glue is cured, or after assembly Apply insulating coating. During assembly, the clamping head 1 is first installed on the fixed plate 3, then the hanging rod 2 is installed on the fixed plate 3 with the hanging rod fixing nut 4, and finally the hook 5 is threaded on the upper end of the hanging rod 2, wherein the hook 5 is suspended and connected on the pole rod 8; the upper part of the clamping head 1 is cylindrical, such as Figure 6 shown.

Embodiment 2

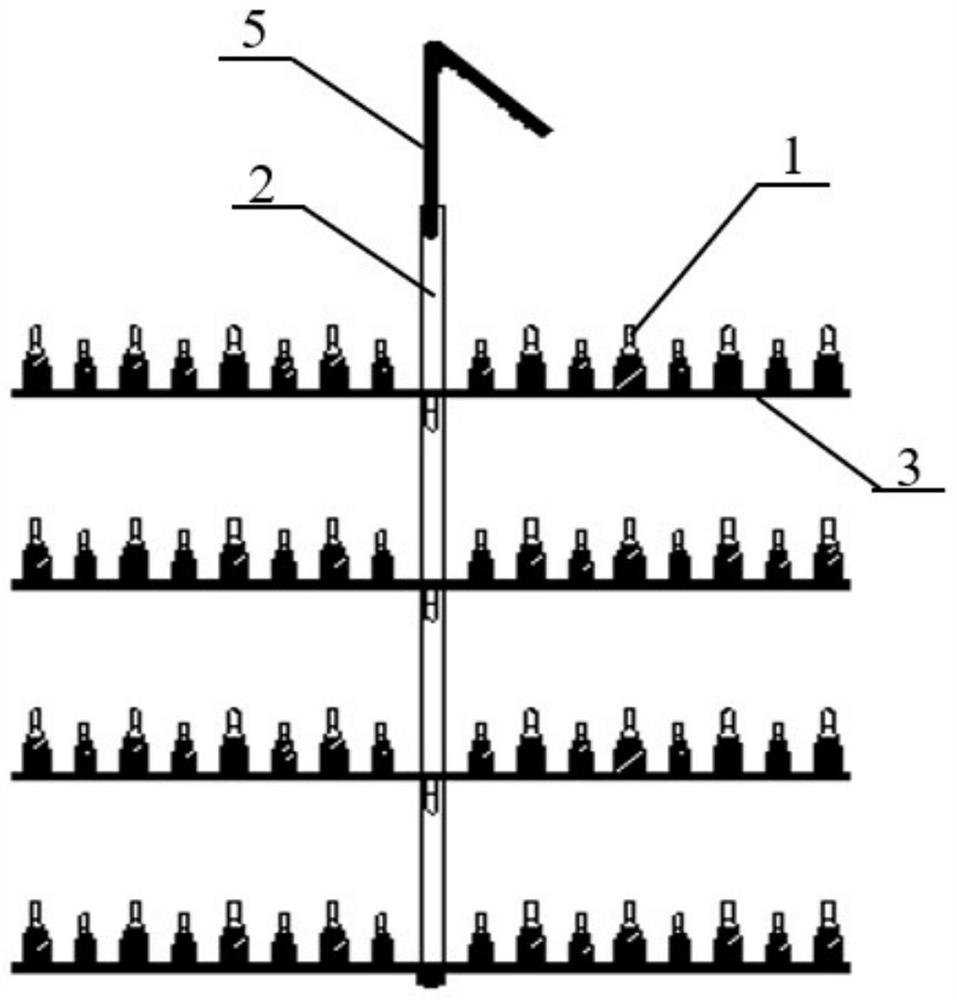

[0040] First, the clamping head 1 is installed on the fixed plate 3, the hanging rod 2 in the suspension device is installed on the fixed plate 3 with the hanging rod fixing nut, and the hook 5 is sleeved on the upper end of the hanging rod 2, and the clamping head 1, The non-contact parts of the hanging rod 2 and the fixed plate 3 are coated with a layer of electroplating glue for insulation, wherein the hook 5 is suspended and connected to the pole 8; the upper part of the clamping head 1 is tapered, such as Figure 7 shown.

[0041] A partitioned surface treatment method for nut-like parts is completed based on the above-mentioned device. First, a layer of insulating electroplating glue is applied to the parts of the clamping head 1 and the fixed plate 3 that are not in contact with the nut workpiece 6, and then the clamping head 1 and the suspension device are fixed on the fixed plate 3, the hook 5 in the suspension device is connected with the external pole 8, and then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com