Drilling fluid chemical osmotic pressure difference testing device

A technology of chemical osmosis and testing equipment, applied in measuring equipment, permeability/surface area analysis, measurement, etc., can solve problems such as distortion of experimental results, difficult operation, difficult measurement of osmotic pressure changes, etc., to achieve wide application range and accurate experimental results , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to have a clearer understanding of the technical features, purposes and beneficial effects of the present invention, the technical solution of the present invention is described in detail below, but it should not be construed as limiting the scope of implementation of the present invention.

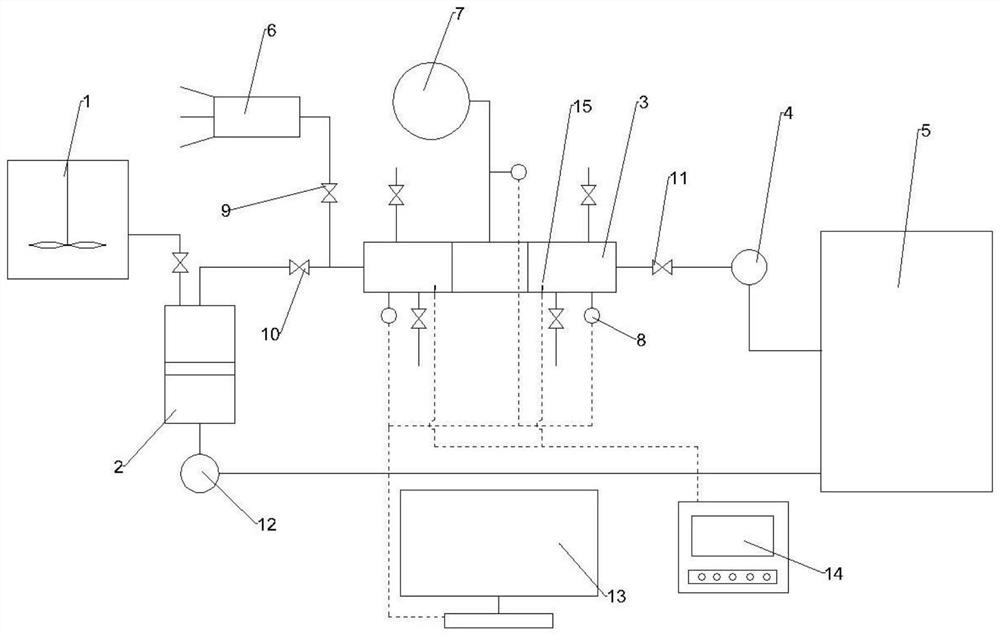

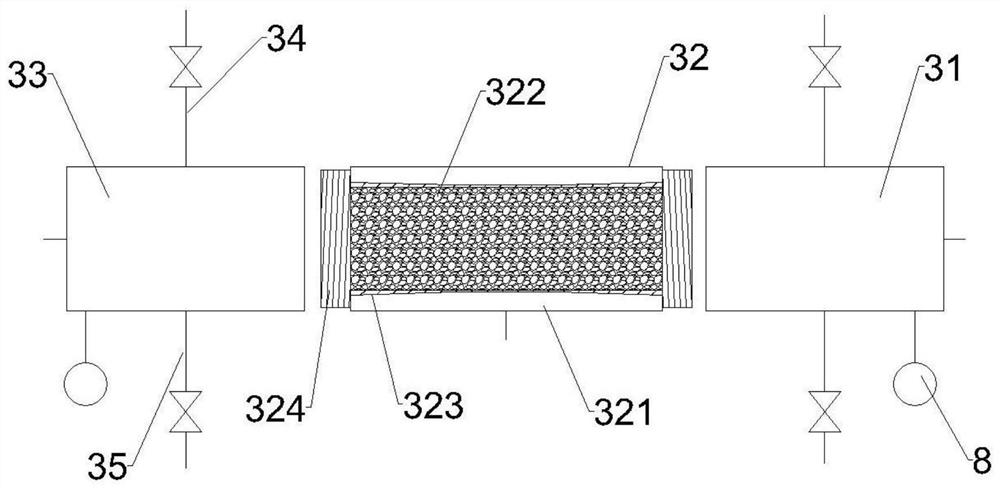

[0022] A drilling fluid chemical osmotic pressure difference testing device, comprising a drilling fluid tank 1, an intermediate container 2, an experimental cylinder 3, a first constant pressure pump 4 and a formation water tank 5 connected in sequence, and the formation water tank 5 is also connected with a second constant pressure The pressure pump 12; the intermediate container 3 is composed of a drilling fluid chamber, a piston and a water chamber. The drilling fluid chamber is provided with a drilling fluid inlet pipe and a drilling fluid outlet pipe. The drilling fluid tank 1 is connected to the drilling fluid chamber through the drilling fluid inlet pipe. Considering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com