Construction and design method of anti-arch subgrade structure of ballastless track in cutting section

A technology of ballastless track and design method, which is applied in the direction of track, road, building, etc., can solve problems such as the difficulty of rectification of arching diseases and serious threats to the operation safety of high-speed railways, and achieve the improvement of anti-arching ability, reasonable construction, and lower basement arch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

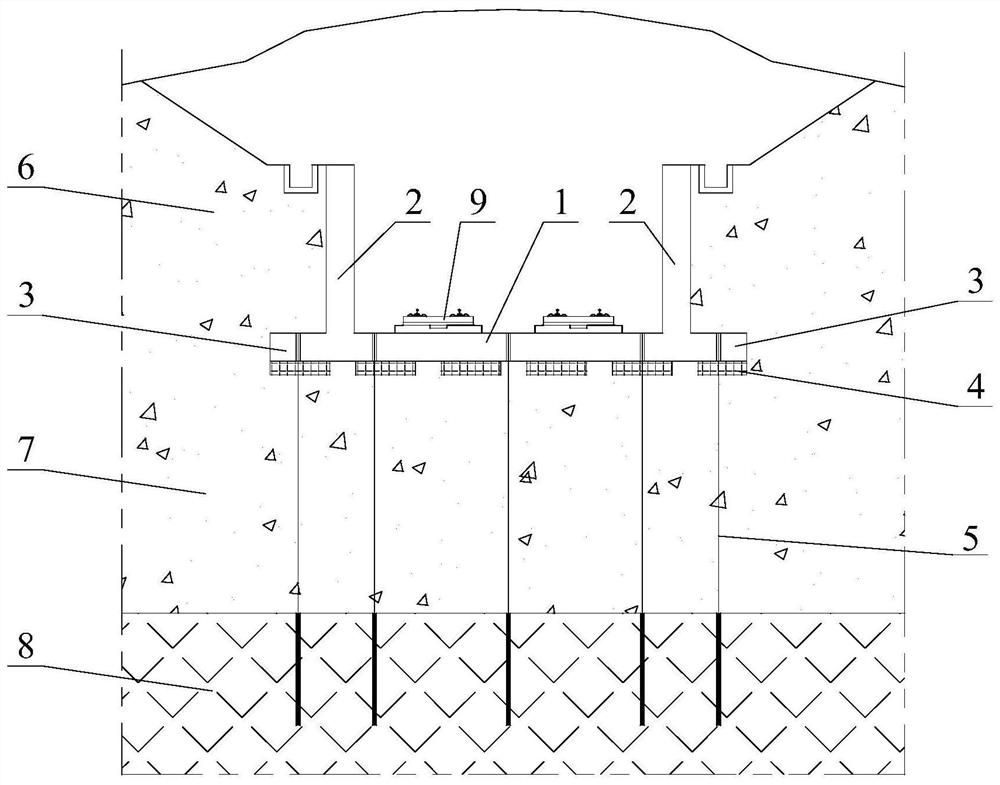

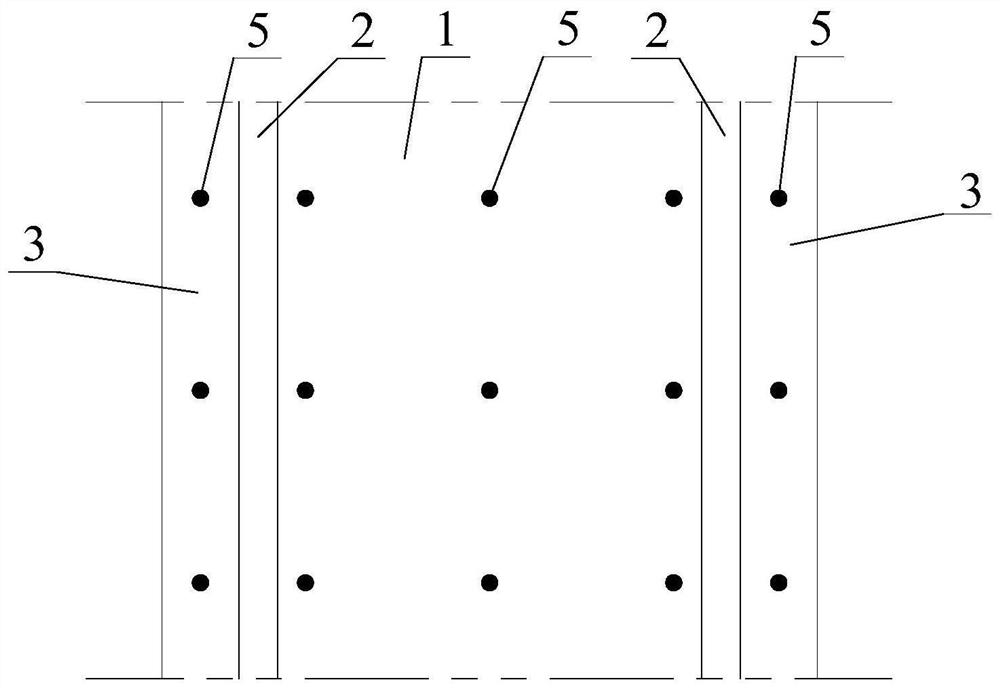

[0050] Such as Figure 1-2 As shown, a ballastless track anti-arch subgrade structure in a cutting section described in this embodiment includes a bearing plate 1 arranged longitudinally along the line, and vertical arm plates 2 are respectively connected to both sides of the bearing plate 1 , the vertical arm plate 2 is used to block the slope soil 6 on the corresponding side of the cutting, at least one side of the bearing plate 1 protrudes from the corresponding vertical arm plate 2, and extends into the corresponding side slope In the soil body 6, the bearing plate 1 is connected with a prestressed anchor cable 5, and the bottom of the prestressed anchor cable 5 extends into the bearing layer 8, and the bottom of the bearing plate 1 is provided with an elastic compression layer 4, at least one of which is The prestressed anchor cable 5 runs through the elastic compressive layer 4 .

[0051] The anti-arch subgrade structure of the ballastless track in the cutting section o...

Embodiment 2

[0056] refer to figure 1 and figure 2 , a construction method of a ballastless track anti-arch subgrade structure in a cutting section of the present invention, comprising the following steps:

[0057] A1. Excavate the cutting slope in stages, and excavate the slope toe to the wing plate 3;

[0058] A2. Leveling the base, excavating trenches at intervals longitudinally, and laying an elastic compressive layer 4 in the trenches;

[0059] A3. Erect the construction formwork on the elastic compression layer 4, place the reinforcement cage of the bearing plate 1, the vertical arm plate 2, and the wing plate 3, and connect the main reinforcements by welding, accurately determine the position of each prestressed anchor cable 5, and reserve the cable hole, and pour concrete;

[0060] A4. Apply the prestressed anchor cable 5, and carry out pressure grouting to the anchor section, and stretch the prestress anchor cable 5 after the grout is solidified, wherein the anchor section is ...

Embodiment 3

[0065] refer to figure 1 and figure 2 , a design method for the anti-arching subgrade structure of the ballastless track in the cutting section described in the embodiment 1 described in the present embodiment, comprising the following steps:

[0066] Based on the structural form and size parameters of the anti-arching subgrade structure of the ballastless track in the cutting section described in Embodiment 1, a subgrade structure design model is established;

[0067] Establish the slope soil model according to the slope size of the cutting section; and make the slope soil model satisfy: when the depth of the load-bearing plate 1 extending into the slope soil 6 and the load-bearing plate 1 and When the angle between the horizontal planes, the output soil weight G S ,

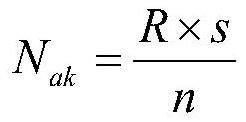

[0068] The self-weight of the soil body G S Input the subgrade structure design model, and output the minimum design parameters of a single prestressed anchor cable 5;

[0069] The final size parameters o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com