Rail transit

A technology of rail transit and track slabs, which is applied in the field of rail transit and can solve problems such as affecting lines, heavy maintenance and repair workload, and hidden dangers of railway transportation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

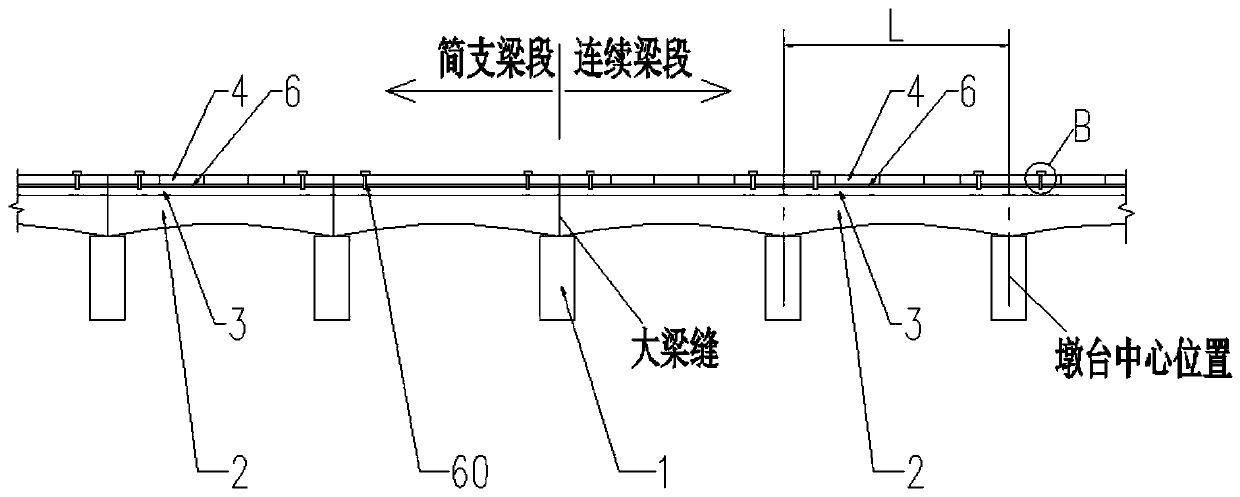

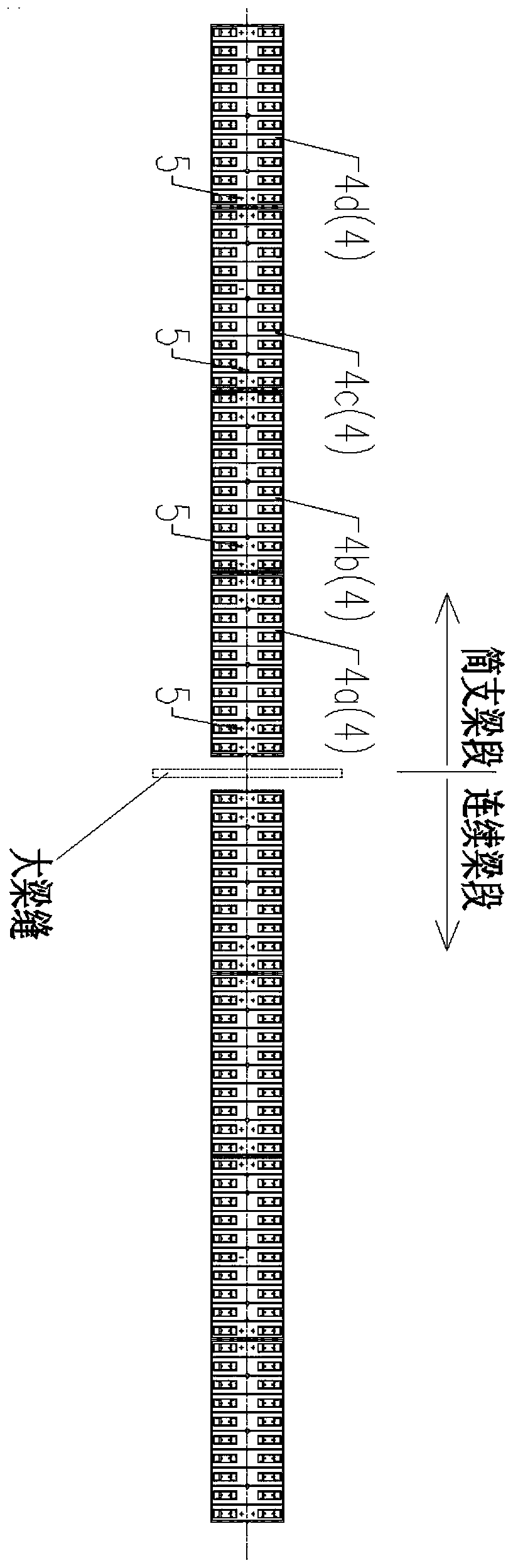

[0055] Embodiment one, such as Figure 1 to Figure 3 ,as well as Figure 5 to Figure 7 shown;

[0056] Determine the target position, which is the position of the girder joint at the junction of the simply supported beam segment and the continuous beam segment.

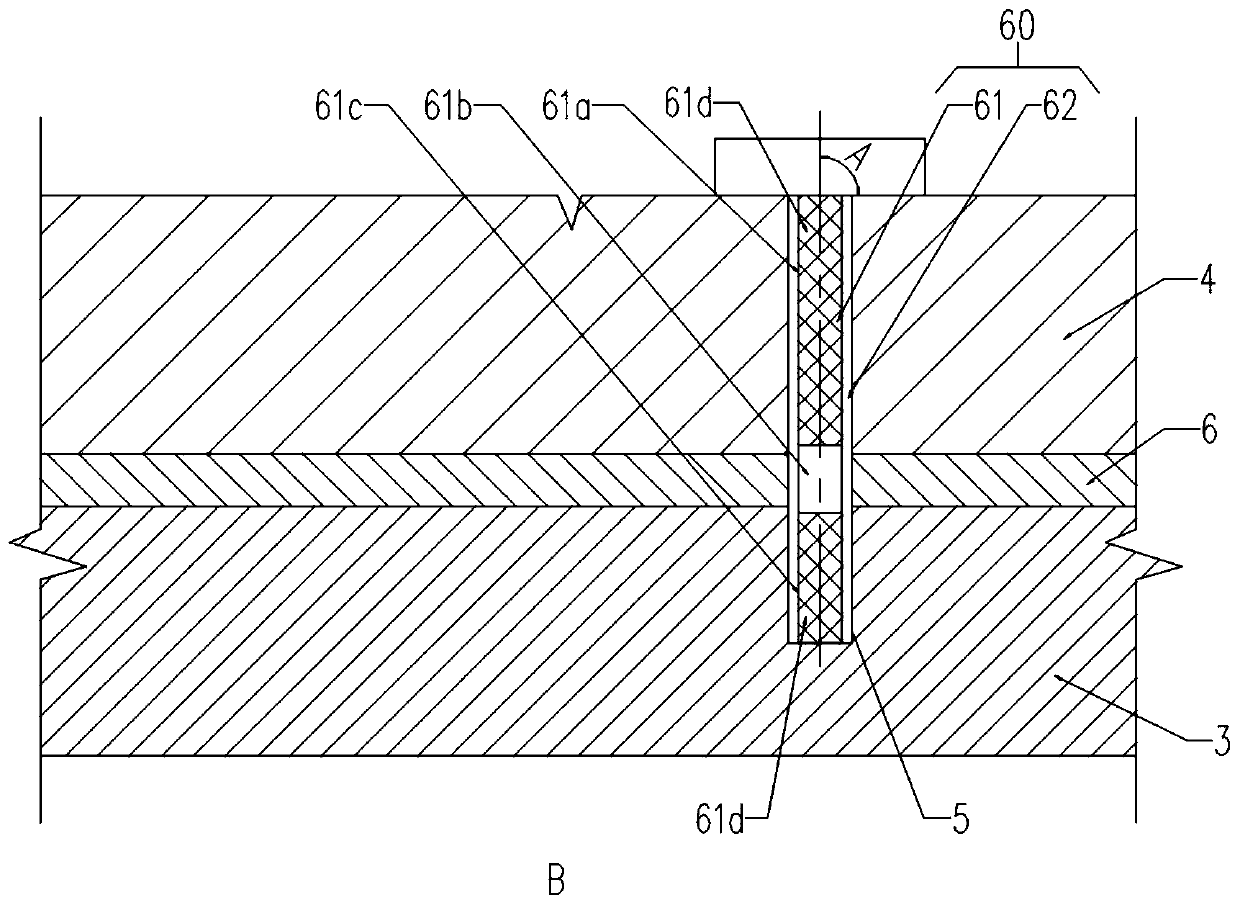

[0057] Among the four track plates 4 on either side of the target position, eight fixing holes 5 are symmetrically formed on the first track plate 4a adjacent to the target position; Eight steel bar heads are used as fixing points, and chemical anchor bolts 60 are implanted into eight fixing holes 5 on the first track plate 4a.

[0058] Eight fixing holes 5 are symmetrically formed on the second track plate 4b adjacent to the first track plate 4a.

[0059] Six fixing holes 5 are symmetrically formed on the third track plate 4c adjacent to the second track plate 4b, wherein the third track plate 4c is connected in sequence with the end of the second track plate 4b away from the target position .

[0060] Four fixi...

Embodiment 2

[0071] Embodiment two, such as figure 1 , figure 2 , Figure 4 , Image 6 as well as Figure 7 as shown,

[0072] The target position is the center position of the pier 1 of the continuous beam segment.

[0073] Among the four track plates 4 on either side of the target position, six fixing holes 5 are symmetrically formed on the first track plate 4 a adjacent to the target position.

[0074] Six fixing holes 5 are symmetrically formed on the second track plate 4b adjacent to the first track plate 4a.

[0075] Four fixing holes 5 are symmetrically formed on the third track plate 4c adjacent to the second track plate 4b, wherein the third track plate 4c is sequentially connected with the end of the second track plate 4b away from the target position .

[0076] Four fixing holes 5 are symmetrically formed on the fourth track plate 4d adjacent to the third track plate 4c, wherein the fourth track plate 4d is sequentially connected with the end of the third track plate 4c ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com