Non-descending plate same-floor drainage system and construction method thereof

A technology of same-layer drainage and lowering plate, which is applied to waterway systems, drainage structures, water supply devices, etc., can solve the problems of difficult maintenance, heavy components, moldy, etc., and achieve the effect of reducing the scope of leakage and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

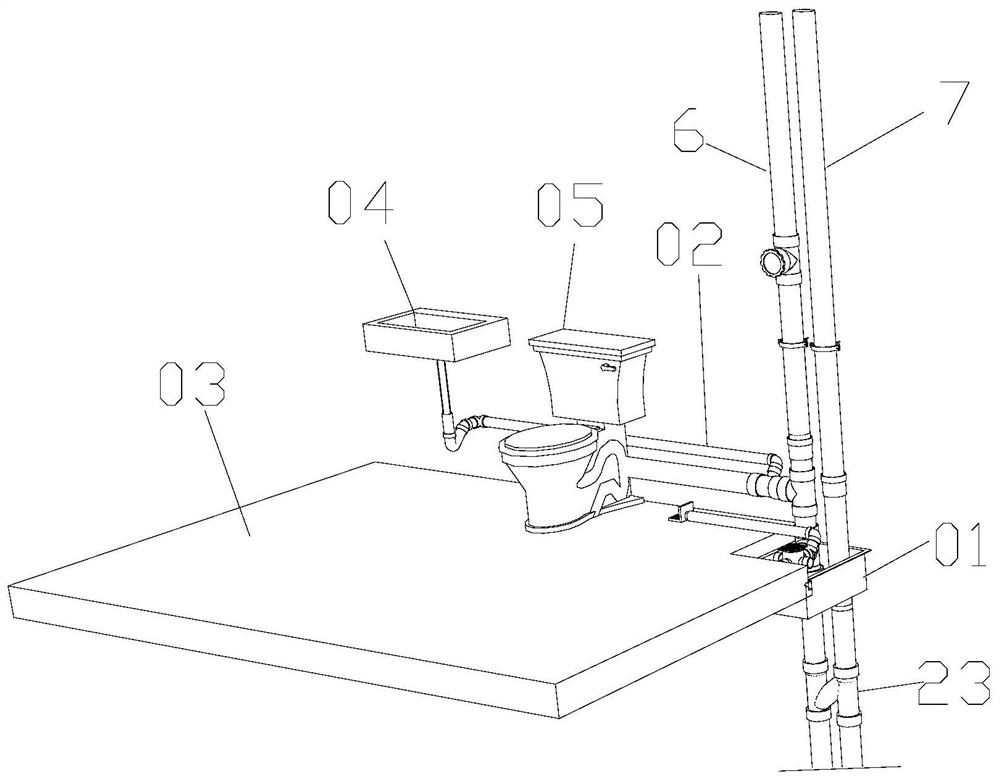

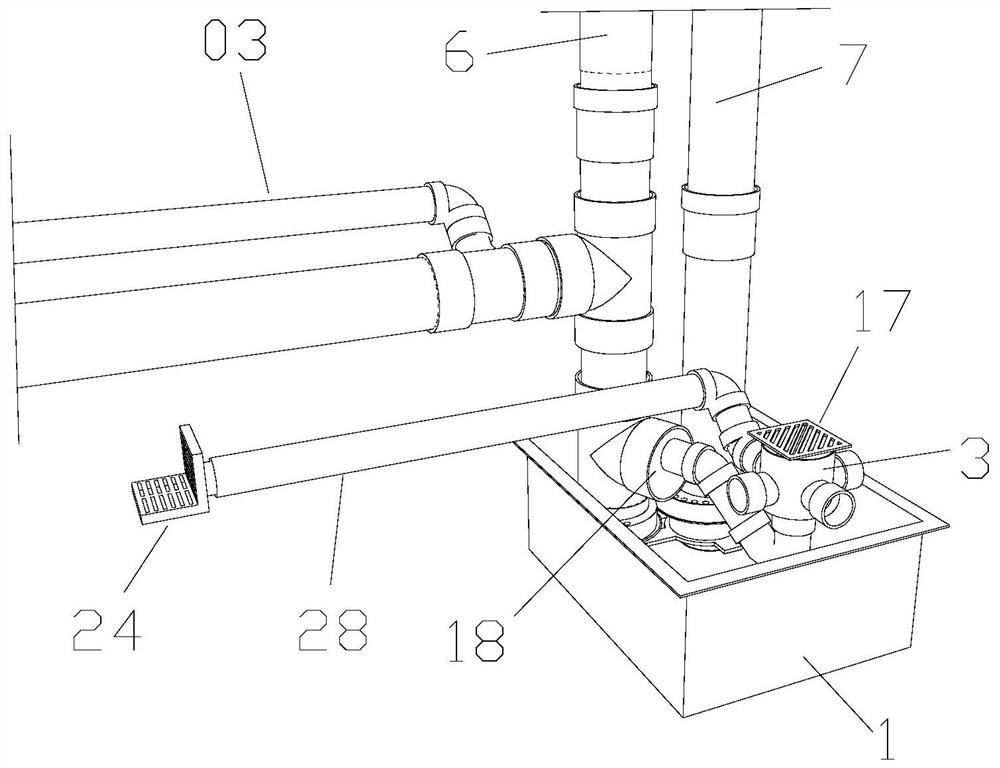

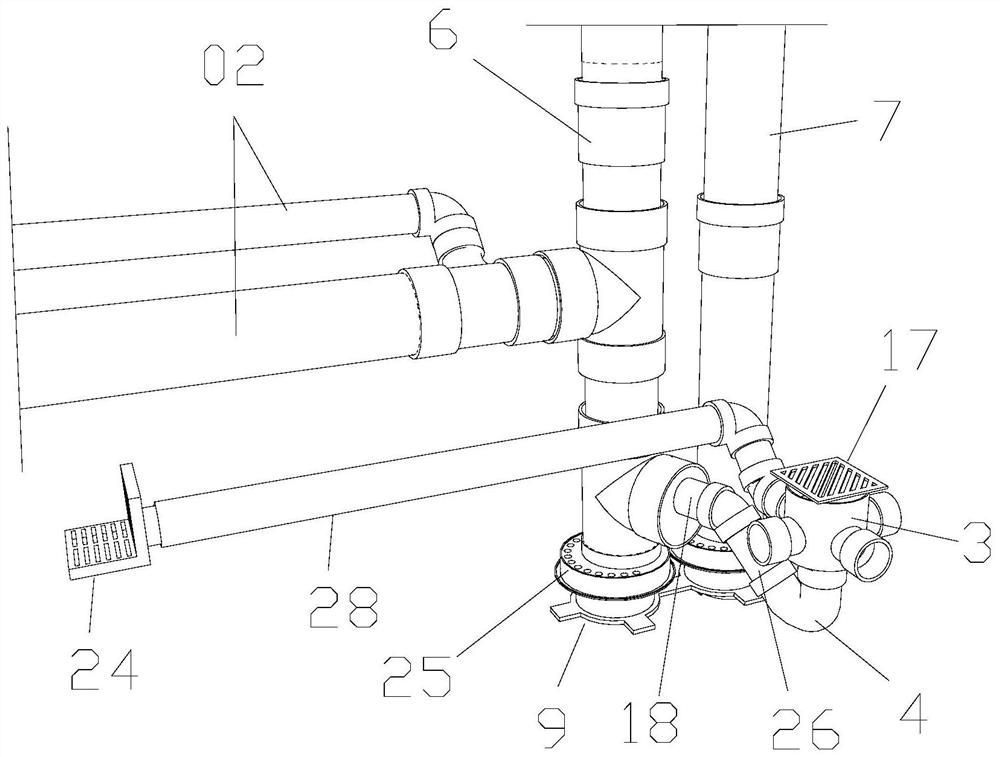

[0070] Reference attached Figure 1 to Figure 5 As shown, the non-falling slab same-floor drainage system in this embodiment includes multiple appliance drainage pipes and the same-floor drainage functional module 01, the same-floor drainage functional module 01 is fixedly connected to the pipe well opening of the floor 03, and the same-floor drainage functional module 01 includes a module box 1 with an open top side and a preset pipe fitting 2. The preset pipe fitting 2 includes a multi-channel floor drain 3, a water tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com