Functionally graded deformation joint structure and manufacturing method

A technology of functional gradient and deformation joints, which is applied in the direction of building structure and construction, to achieve the effect of improving overall performance, reducing cost, and enhancing overall functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

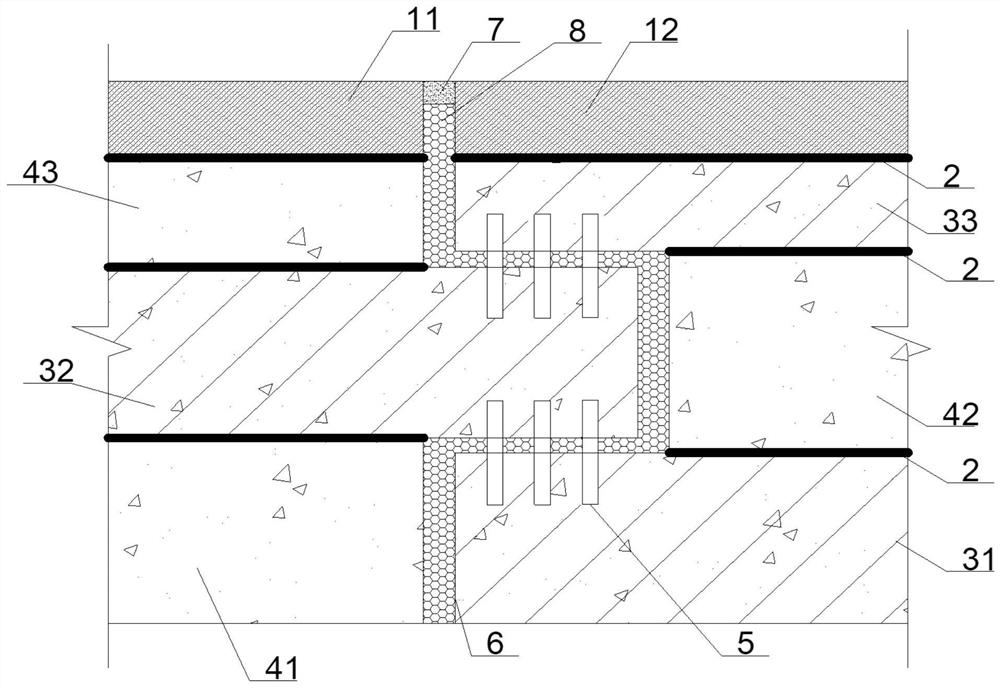

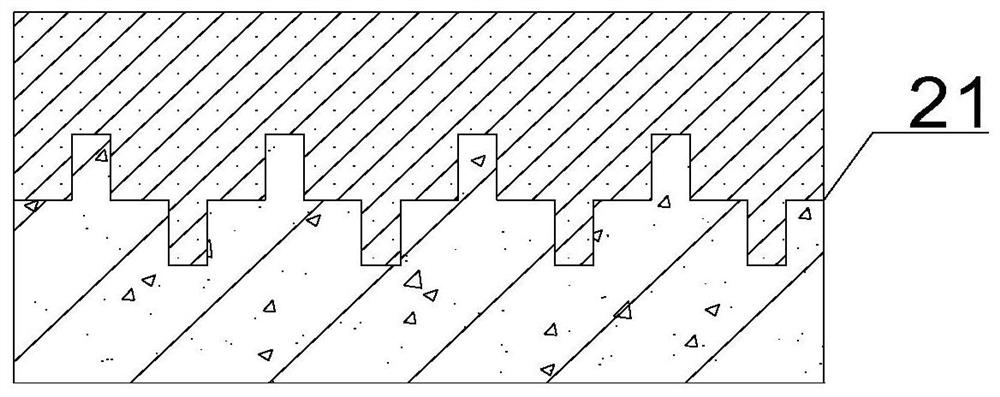

[0045] like Figure 1-2 As shown, a functional gradient deformation seam structure, the deformation seam is a tongue-and-groove seam 6, which can maximize the waterproof ability of the deformation seam in terms of structural design. Set different concrete layers in different thickness directions on both sides of the groove joint 6 to construct a functional gradient concrete layer. A sealing material 7 is arranged in the tongue and groove seam 6 . The high impermeability and anti-cracking concrete layers on the left and right sides of the groove 6 are the first high-impermeability and anti-cracking concrete layer 11 and the second high impermeability and anti-cracking concrete layer 12 respectively.

[0046] The first ordinary concrete layer 41 is located on the concave surface of the grooved joint 6, and the second ultra-high toughness concrete layer 32 is placed on the convex surface, and the upper and lower adjacent layers of the second ordinary concrete layer 42 are both u...

Embodiment 2

[0055] The concrete steps of making the functional gradient deformation joint structure of embodiment 1 are as follows:

[0056] S1. Pouring the first ordinary concrete layer 41 at the bottom of the left side and the first ultra-high toughness concrete layer 31 at the bottom of the right side, and reserving 5 holes for connectors on the formwork for pouring the first ultra-high toughness concrete layer 31;

[0057] S2. The upper surface of the left and right sides of the soil layer and the lower surface of the formwork of the concrete layer to be poured are subjected to interface strengthening treatment;

[0058] S3, respectively pouring the second ultra-high toughness concrete layer 32 on the first ordinary concrete layer 41 and pouring the second ordinary concrete layer 42 on the first ultra-high toughness concrete layer 31, when pouring the second ultra-high toughness concrete layer 32, A connecting piece 5 is arranged inside it;

[0059] S4. Perform interface strengthenin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com