Temperature control method and device for diesel particulate filter (DPF) during regeneration

A temperature control method and DPF technology, which is applied to the electronic control of mufflers, exhaust devices, exhaust treatment devices, etc., can solve the problems of DPF burnout and the inability to guarantee the absolute safety of DPF temperature, so as to reduce the temperature before and ensure the temperature Absolutely safe, prevent burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

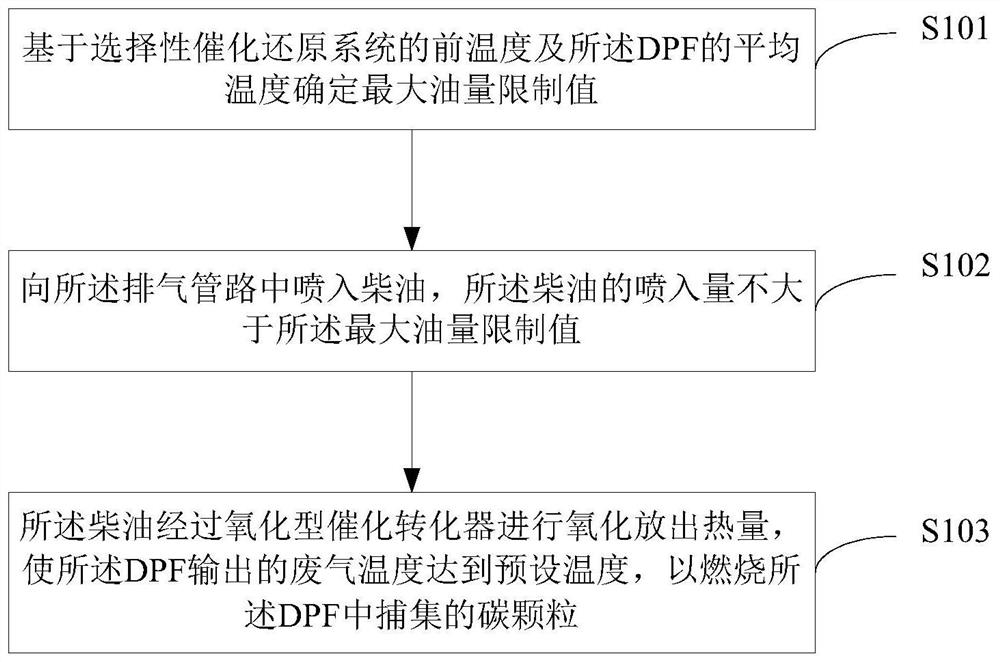

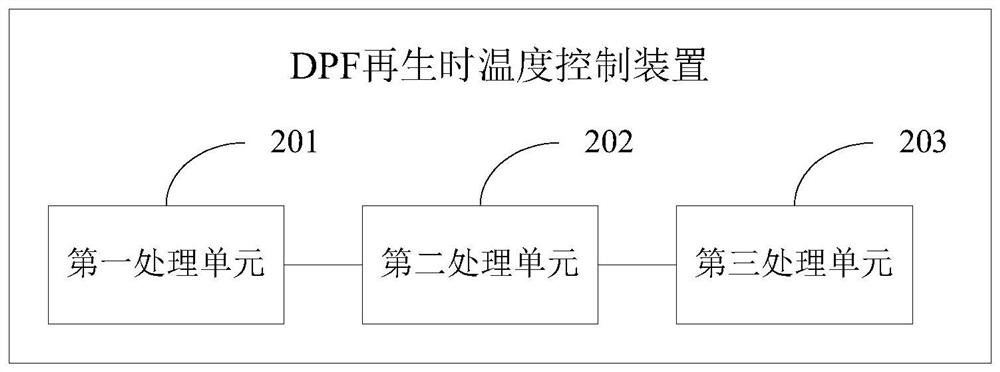

[0033] This application provides a temperature control method and device during DPF regeneration, which is used to prevent the particulate matter filter DPF from being burned due to excessive temperature during regeneration, by increasing the maximum oil quantity limit based on the front temperature of the selective catalytic reduction system and the average temperature of the DPF Function, the limited oil quantity before the DPF and the limited oil quantity before the selective catalytic reduction system take the smaller one as the final limited oil quantity, and quickly reduce the front temperature of the selective catalytic reduction system by reducing the limited oil quantity of the HC injection quantity to prevent DPF burned.

[0034] The purpose of the invention of the present application is: how to avoid the problem of DPF burning and ensure the absolute safety of the temperature during DPF regeneration.

[0035] The following will clearly and completely describe the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com