Worm steering type rotary speed reducer for multi-point drive tracking

A rotary reducer and multi-point drive technology, which is applied in the direction of electromechanical devices, mechanical equipment, electric components, etc., can solve problems such as difficulties, achieve cost savings, prevent external forces from pushing the solar tracking system, and improve the rigidity of the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

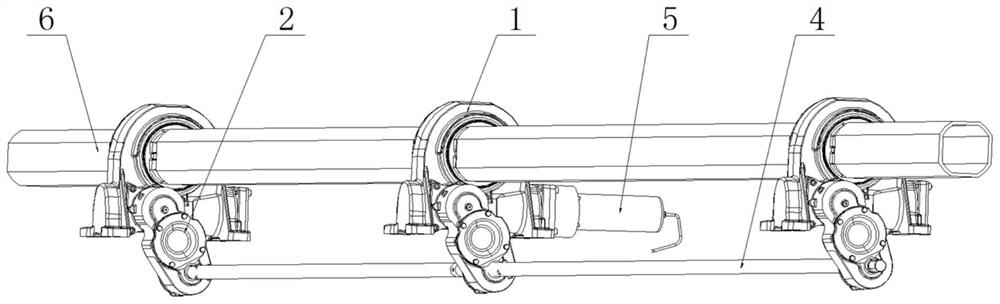

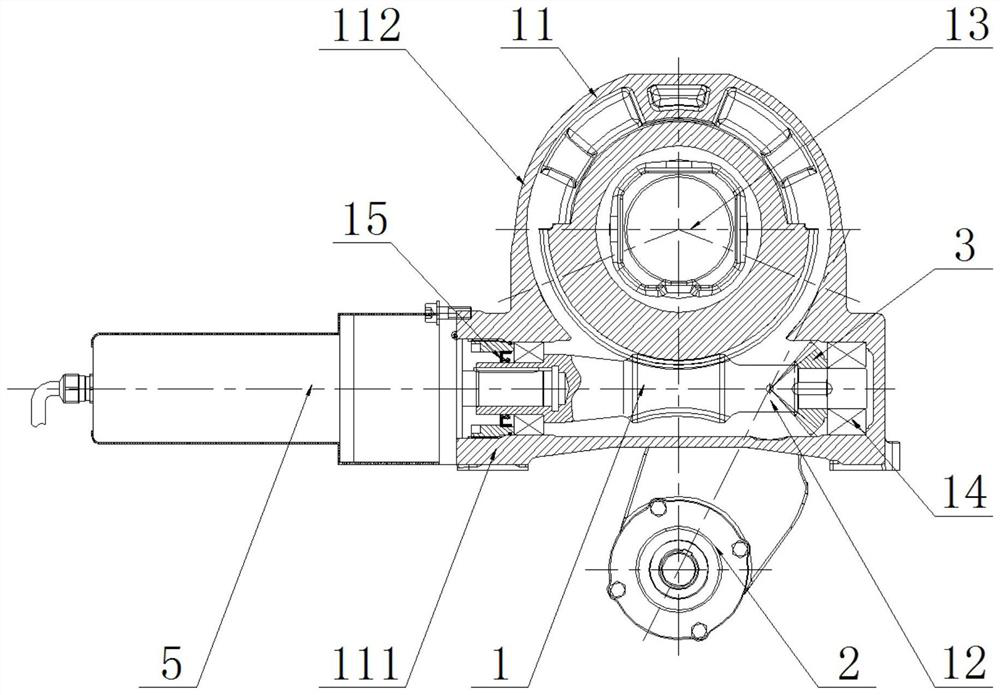

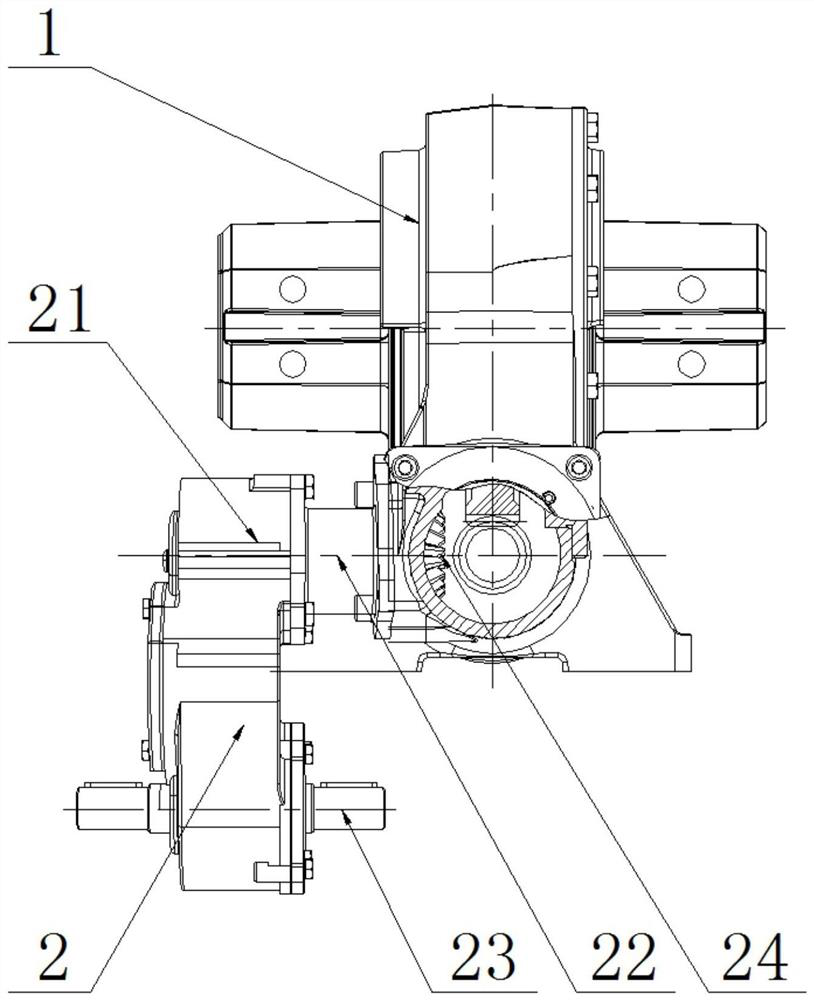

[0043] Such as Figure 1 ~ Figure 4 As shown, a worm-steering multi-point drive tracking rotary speed reducer in this embodiment includes a plurality of worm gear rotary drive devices 1 arranged at intervals in front and rear, and the worm gear rotary drive device 1 includes a base 11, The base 11 includes a shaft housing 111 and a seat ring 112, the shaft housing 111 is provided with a worm 12, the seat ring 112 is provided with a gear shaft 13, the worm 12 is meshed with the gear shaft 13, adjacent A main beam 6 is arranged between the gear shafts 13 of two worm and gear rotary drive devices 1; the static self-locking between the worms 12 and the gear shafts 13 of multiple worm and gear rotary drive devices 1 can effectively prevent external forces from pushing the solar tracking system, so as to avoid System device damage occurs;

[0044]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com