Semi-submersible microscope objective with protective element and use of the same in multiphoton imaging method

A microscope objective, semi-submersible technology, applied in microscopes, optical components, microlithography exposure equipment, etc., can solve the problem of unusable microscope objective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

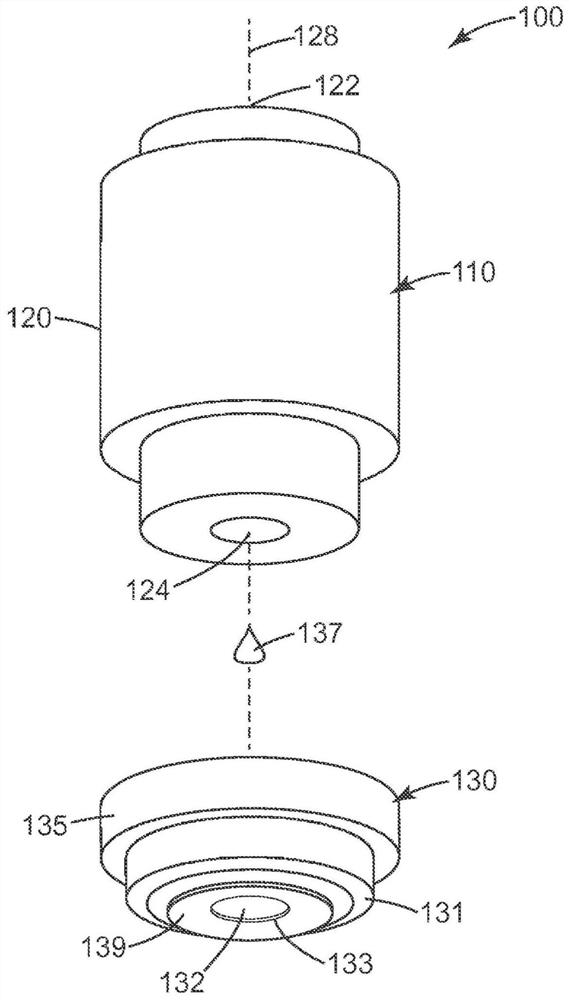

[0056] In a first embodiment, the present invention provides a semi-submersible microscope objective, comprising:

[0057] Microscope objectives, including:

[0058] a protective cylinder having an optical entrance and an optical exit; and at least one optical element disposed within the protective cylinder and along an optical path extending between the optical entrance and the optical exit; and

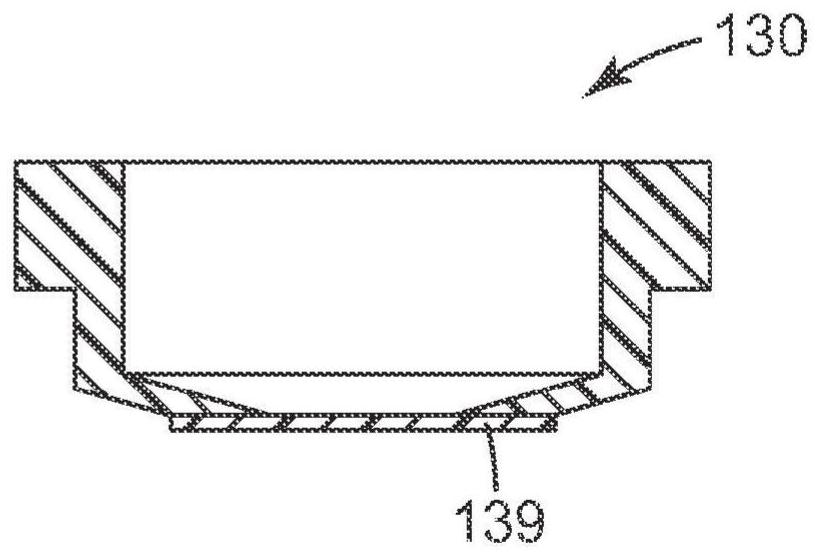

[0059] A protective element, which is attached to the microscope objective, seals the optical outlet but not the optical entrance, wherein the transparent portion of the protective element is aligned with the light path, and wherein the protective element can be separated from the microscope objective without damaging the microscope objective.

[0060] In a second embodiment, the present invention provides the semi-submersible microscope objective according to the first embodiment, wherein the protective element mechanically engages the microscope objective.

[0061] In a third emb...

Embodiment 1

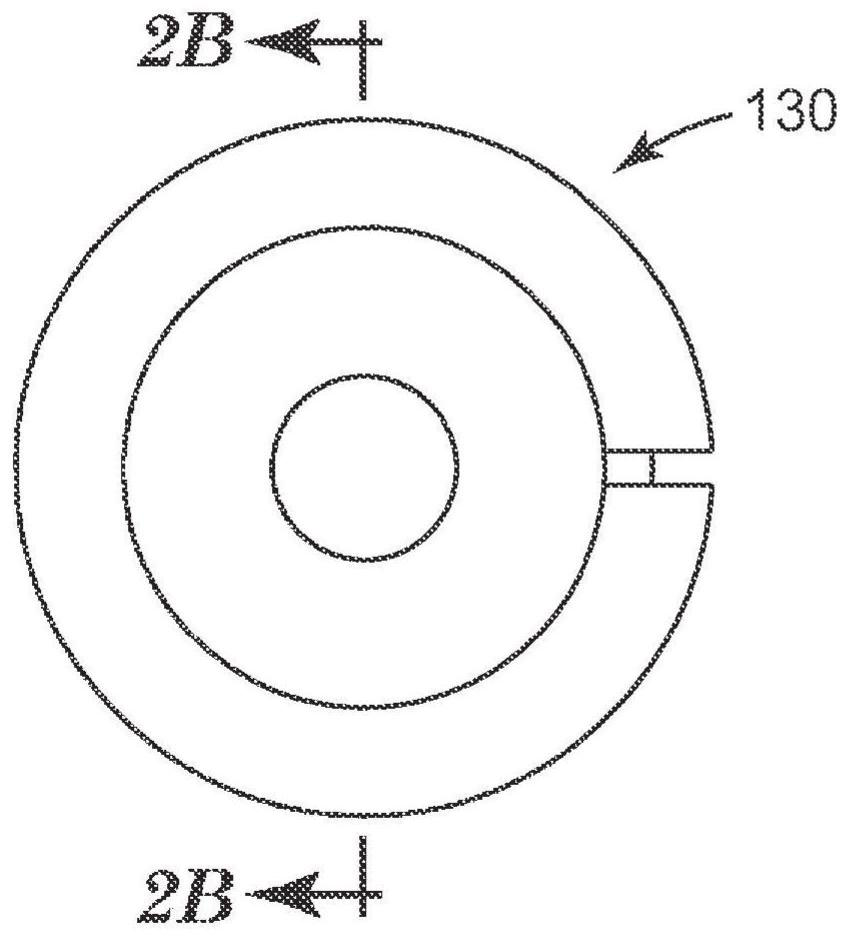

[0085] In this example, a microscope coverslip (approximately 170 to 190 microns) was glued to a protective element made of Delrin, which was clamped directly to a Zeiss 40x / 1.0 oil iris microscope objective (available at On protective tubes from Carl Zeiss Microscopy, LLC, Thornwood, New York, when used for multiphoton imaging and typically in figure 1 As shown in , the objective has a tapered end with a centrally positioned lens corresponding to the optical exit. The protection element is in Figures 2A-2C shown in . The protective element was then positioned so that the cover glass touched the lens at the optical exit, and a drop of Zeiss IMMERSOL 518F immersion lens oil was added between the lens surface and the cover glass to eliminate air.

[0086] Several structures were fabricated using semi-submersible microscope objectives made from liquid photoresists of various compositions. Figure 4 Scanning electron micrographs showing some simple geometries stacked on the z-...

Embodiment 2

[0091] An oil immersion microscope objective (4OX magnification, NA = 1.0, available from Carl Zeiss Microscopy, LLC) was coated with a thin layer of polyvinyl alcohol (PVA). A 10% by weight solution of PVA in water (6,000 g / mole, 80% hydrolyzed, Cat. No. 22225 from Polysciences, Inc., Warrington, Pennsylvania) was applied to the exposed lens and the surrounding metal at the immersion end of the microscope objective. Adjust the microscope objective so that excess solution flows off the final lens surface to provide a suitably thin clear protective coating. Place the coated microscope objective in an oven at 50 °C for 2 minutes to facilitate drying.

[0092] The coated end of the resulting semi-submersible microscope objective was dipped into the liquid photoresist that had been coated on the silicon substrate. The photoresist formulation consisted of 35 parts by weight of EPON 828 bisphenol A diglycidyl ether available from Momentive, Houston, Texas; 30 parts by weight of ER...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com