A kind of ultra-high voltage aluminum electrolytic capacitor and its manufacturing method

A technology for aluminum electrolytic capacitors and manufacturing methods, which is applied in the direction of electrolytic capacitors, capacitors, capacitor parts, etc., can solve problems such as inability to achieve higher withstand voltage values, working electrolyte leakage failures, etc., to avoid the impact of rising mains power, Ensure low impedance, withstand superimposed ripple and high voltage, and increase the effect of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

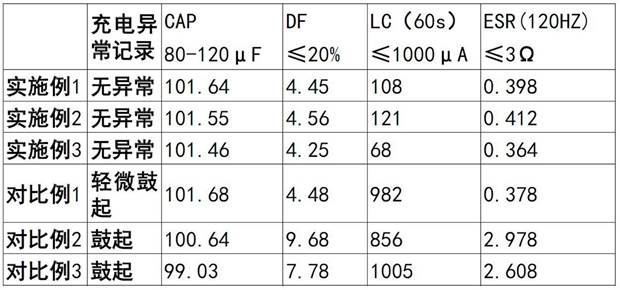

Examples

Embodiment 1

[0034] The present embodiment provides a method for manufacturing an ultra-high voltage aluminum electrolytic capacitor. The size of the capacitor is 18*50. The manufacturing method includes the following steps:

[0035] (1) Core package winding: The electrolytic paper is interposed between the anode foil and the cathode foil and the core package is wound.

[0036] Among them, the anode foil withstand voltage is 690V, and the specific capacity is 0.46μf / cm 2 ; Before step (1), the anode foil before winding is immersed in a chemical conversion solution for chemical conversion repair treatment and phosphorus treatment, wherein the chemical conversion liquid contains 10wt% of boric acid, 15wt% of ammonium adipate, and the balance is water The mixed acid turns into a liquid. The phosphorus treatment refers to phosphoric acid treatment at 55 to 70°C.

[0037] Wherein, the electrolytic paper is a 4-layer composite electrolytic paper.

[0038] (2) Impregnation step: Immerse the wo...

Embodiment 2

[0044] The present embodiment provides a method for manufacturing an ultra-high voltage aluminum electrolytic capacitor. The size of the capacitor is 18*50. The manufacturing method includes the following steps:

[0045] (1) Core package winding: The electrolytic paper is interposed between the anode foil and the cathode foil and the core package is wound.

[0046] Among them, the anode foil withstand voltage is 690V, and the specific capacity is 0.46μf / cm 2 ; Before step (1), the anode foil before winding is immersed in a chemical conversion solution for chemical conversion repair treatment and phosphorus treatment, wherein the chemical conversion liquid contains 5wt% of boric acid, 15.5wt% of organic acid, and the balance is pure water chemical liquid. The phosphorus treatment refers to phosphoric acid treatment at 55 to 70°C.

[0047] Wherein, the electrolytic paper is a 4-layer composite electrolytic paper.

[0048] (2) Impregnation step: Immerse the wound core package ...

Embodiment 3

[0054] The present embodiment provides a method for manufacturing an ultra-high voltage aluminum electrolytic capacitor. The size of the capacitor is 18*50. The manufacturing method includes the following steps:

[0055] (1) Core package winding: The electrolytic paper is interposed between the anode foil and the cathode foil and the core package is wound.

[0056] Among them, the anode foil withstand voltage is 690V, and the specific capacity is 0.46μf / cm 2 ; Before step (1), the anode foil before winding is immersed in a chemical conversion solution for chemical conversion repair treatment and phosphorus treatment, wherein the chemical conversion liquid is a pure boric acid conversion liquid containing 25wt% boric acid and the balance is water. The phosphorus treatment refers to phosphoric acid treatment at 55 to 70°C.

[0057] Wherein, the electrolytic paper is a 4-layer composite electrolytic paper.

[0058] (2) Impregnation step: Immerse the wound core package in the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com