Fruit picking up equipment

A kind of equipment and fruit technology, applied in the direction of agricultural machinery and implements, applications, harvesters, etc., can solve the problems of a large amount of labor input, complex terrain of fruit growth, easy rolling of fruits and inconvenient picking, etc., and achieve the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

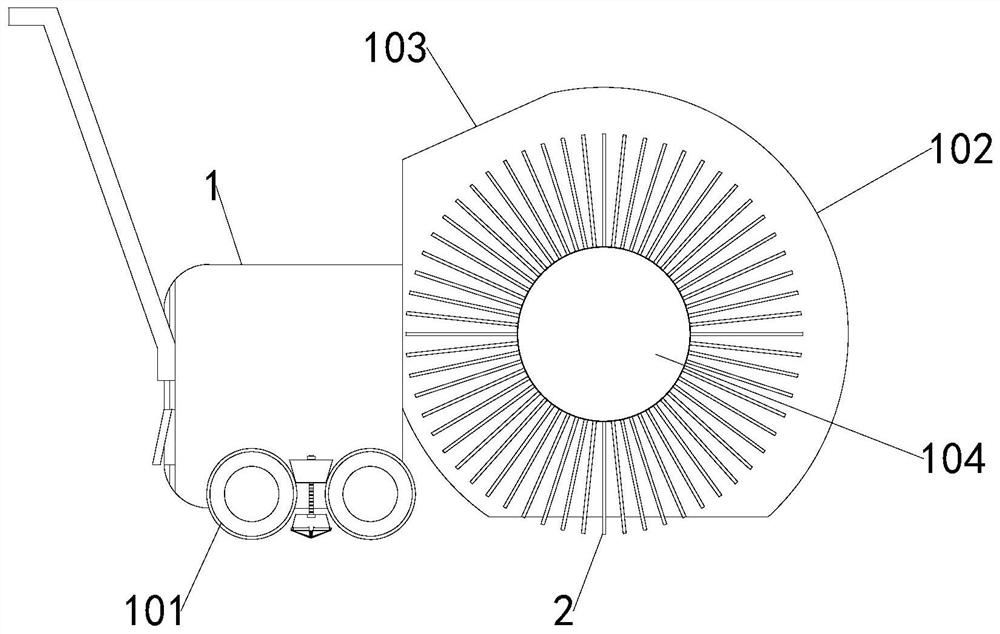

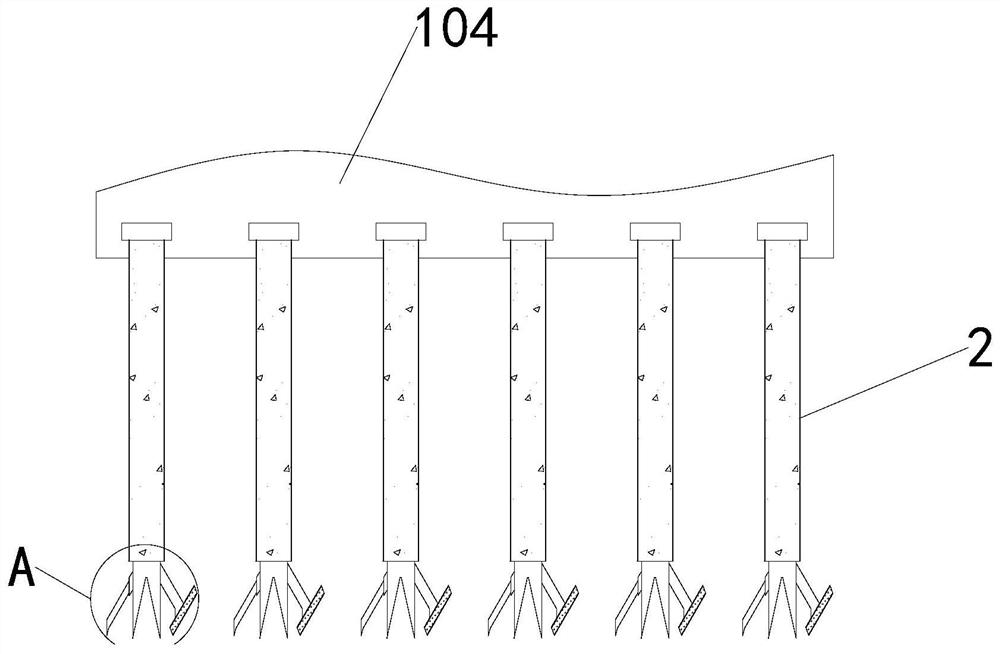

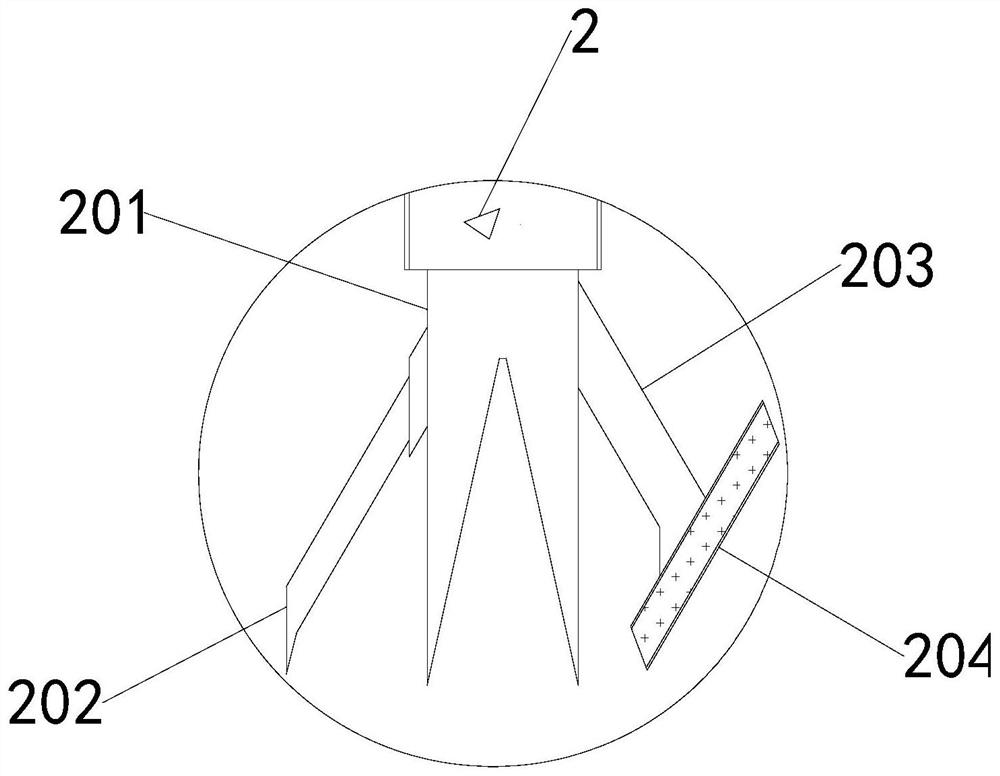

[0025] see Figures 1 to 8 Among them, in the embodiment of the present invention, a fruit picking device includes: a device body 1, a rotating roller 104, a guide rod 2 and a fixed block 3, a pick-up component is arranged on the right side of the device body 1, and the bottom of the device body 1 Obstacle-surmounting parts are provided, and the device body 1 is in contact with the gap between the two ends of the feeding chamber 102 , and two walking wheels 101 are installed at the front and rear ends of the device body 1 .

[0026] Preferably, the pick-up component includes: a rotating roller 104 and a guide rod 2, the rotating roller 104 is arranged on the left side of the inside of the feeding chamber 102, and the feeding chamber 102 is round as a whole, and the bottom of the feeding chamber 102 is horizontal It is horizontally arranged, and the top left side of the feeding chamber 102 is integrally provided with a slope 103, and the bottom of the slope 103 is open, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com