Camellia oleifera fruit and shell sorting equipment

A technology for sorting camellia husks, which is applied in the fields of shelling, solid separation, and separation of solids from solids with airflow. It can solve problems such as inconsistent quality, easy cracking of the shell, and inability to achieve better sorting results. , to achieve the effect of guaranteeing the sorting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

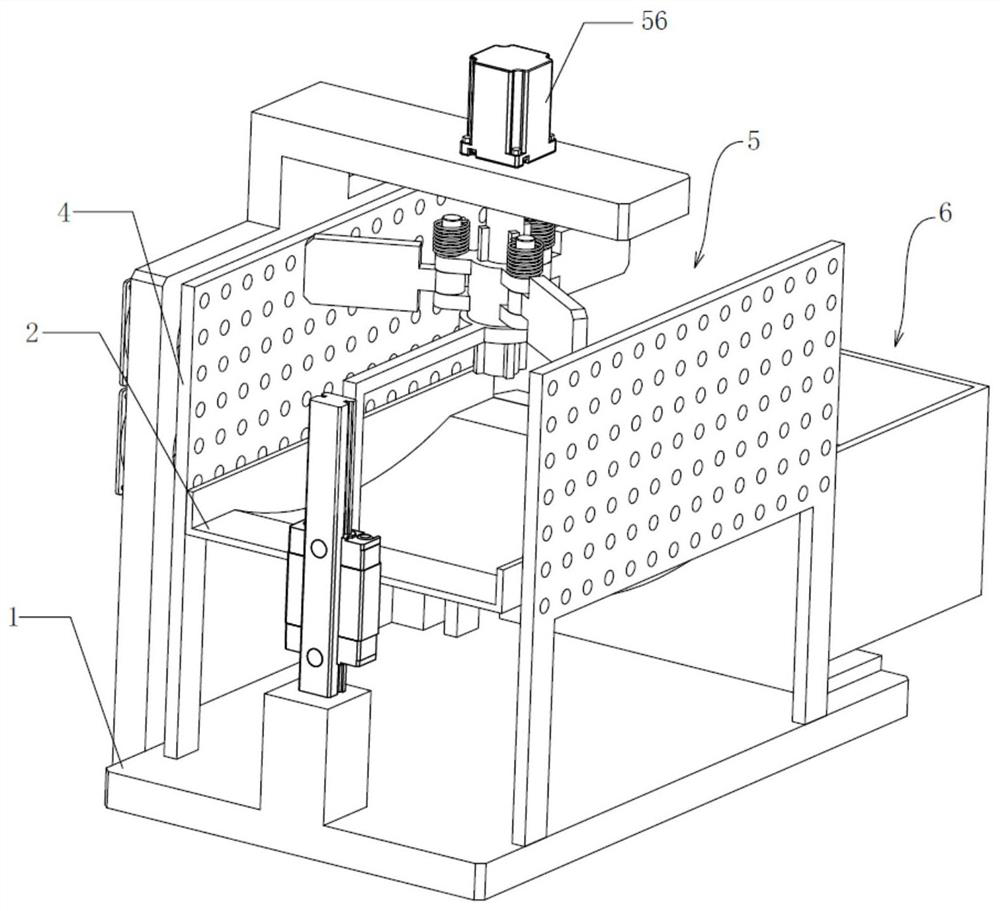

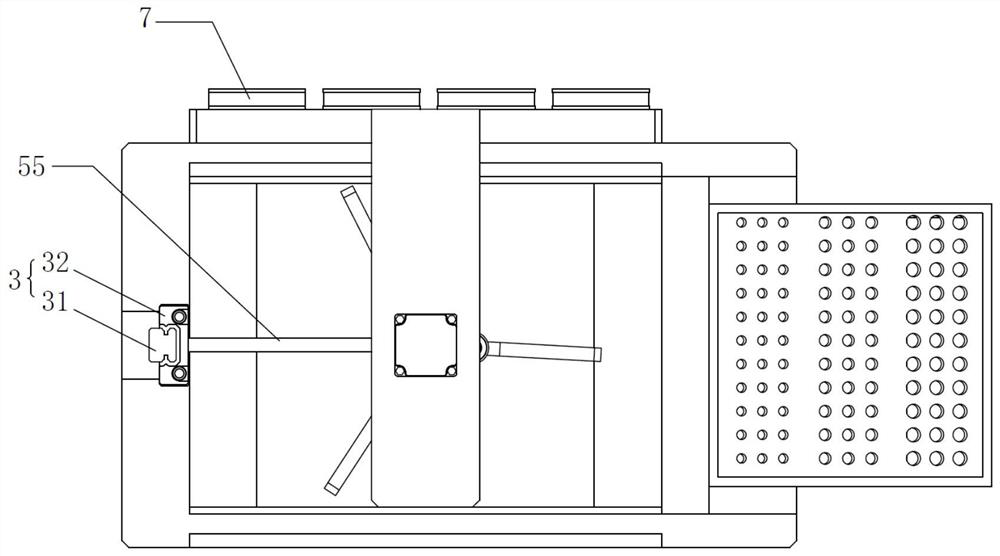

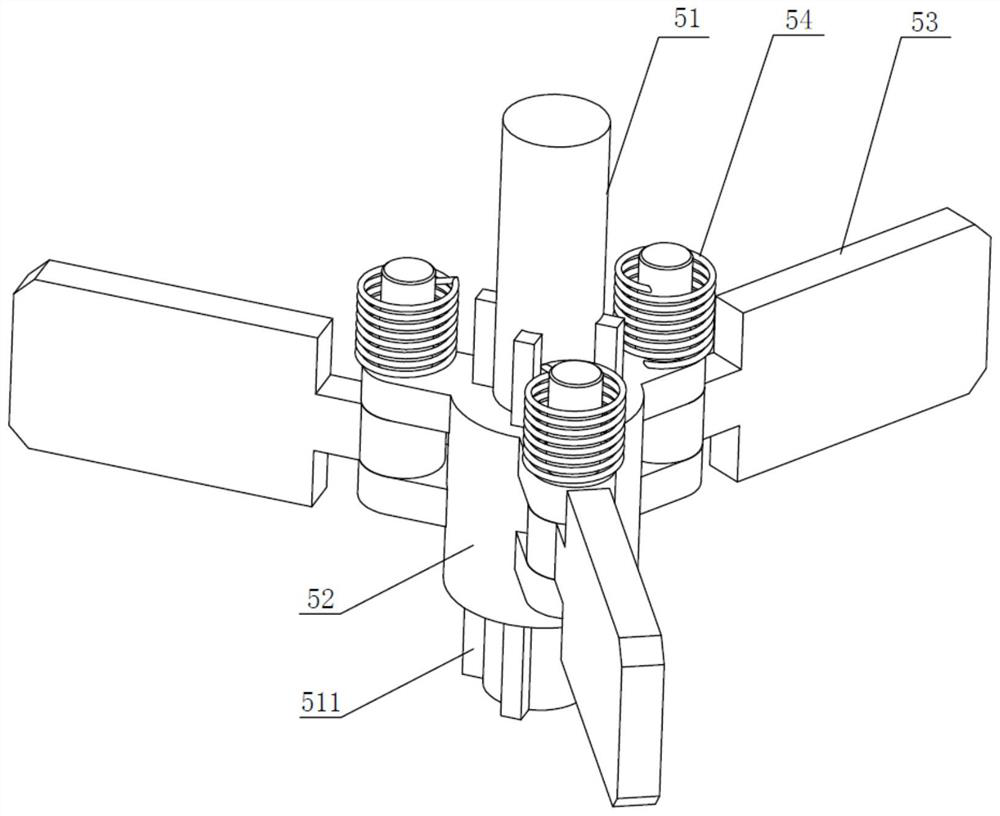

[0023] see Figure 1 to Figure 4 , the present invention provides a technical solution:

[0024] A camellia oleifera husk sorting device, comprising a frame 1, a flexible belt 2, a linear drive mechanism 3, a screen plate 4, a flexible beating mechanism 5, a fruit sorting mechanism 6 and a fan 7, wherein:

[0025] One end of the flexible belt 2 is installed on the frame 1 through a support frame. The linear drive mechanism 3 includes a linear guide rail 31 and a linear motor 32. The linear guide rail 31 is installed on the frame 1 in a vertical state through bolts, and the linear motor 32 is movably installed on the frame 1. on the linear guide rail 31, and the other end of the flexible belt 2 is fixedly connected with the linear motor 32, so when the linear motor 32 reciprocates along the linear guide rail 31, it can drive the flexible belt 2 to fluctuate. On the frame 1 and located on both sides of the flexible belt 2, several fans 7 are respectively installed in the column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com