Flocculation-intensifying experimental device suitable for micro-fine-particle hematite

An experimental device, the technology of hematite, is applied in the direction of the swirling axial reverse device, swirling device, solid separation, etc., to achieve the effect of ensuring the flocculation effect, ensuring the strength of the flocculation, and strengthening the flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

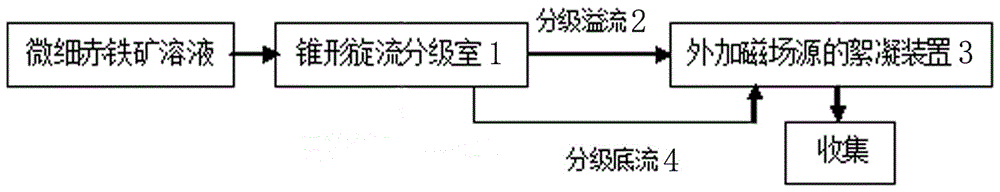

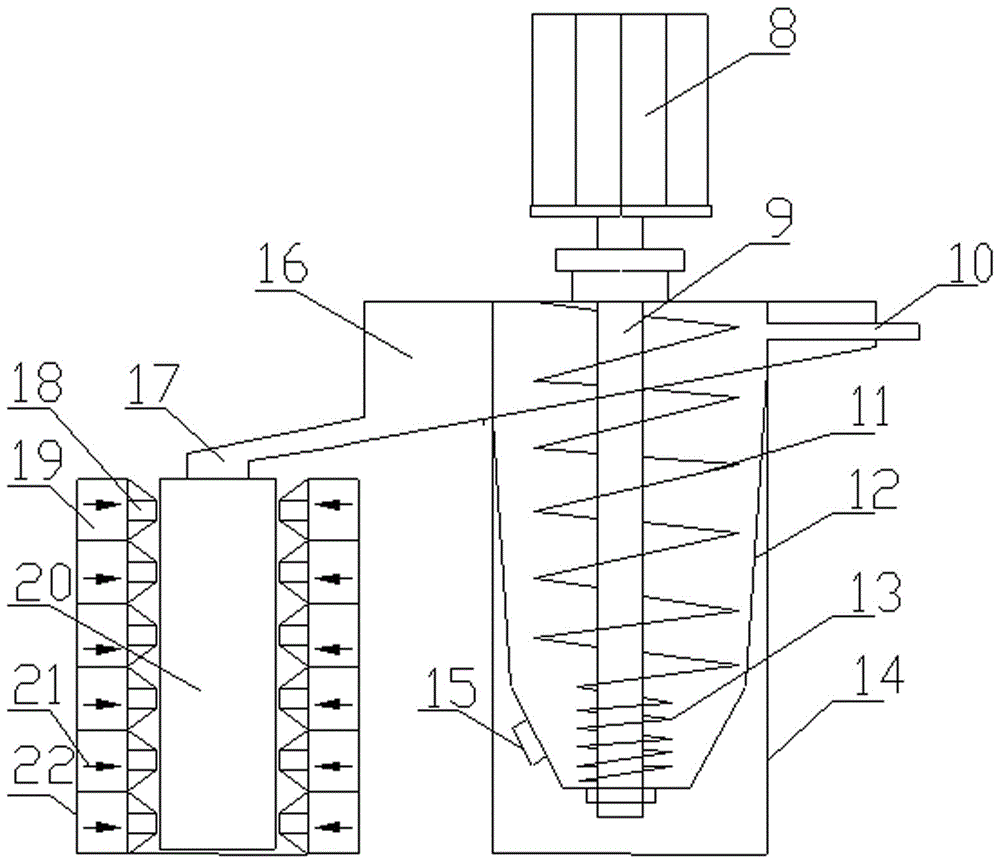

[0024] Such as figure 1 As shown, the hematite first enters the conical cyclone classification chamber 1 for preliminary classification, the classification overflow 2 enters the flocculation device 3 with an external magnetic field source, and the overflow product is collected after flocculation; after that, the classified underflow 4 enters an external magnetic field The flocculation device 3 of the source is used for flocculation, and finally a flocculation experiment of fine hematite is completed. The structural features of the conical swirl classifying chamber 1: the two-stage conical cavity structure can realize the classification of minerals according to the particle size; the conical swirl classifying chamber 1 is designed with internal spiral rotating blades of different diameters to make the ore slurry fluidized bed form to achieve mineral grading by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com