Method for quickly clearing raw material filter

A filter and raw material technology, which is applied in the field of fast-clearing raw material filters, can solve the problems of safety risks, toxic and harmful benzene media, and impact on the environment, and achieve the effects of reducing economic losses, being easy to operate, and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

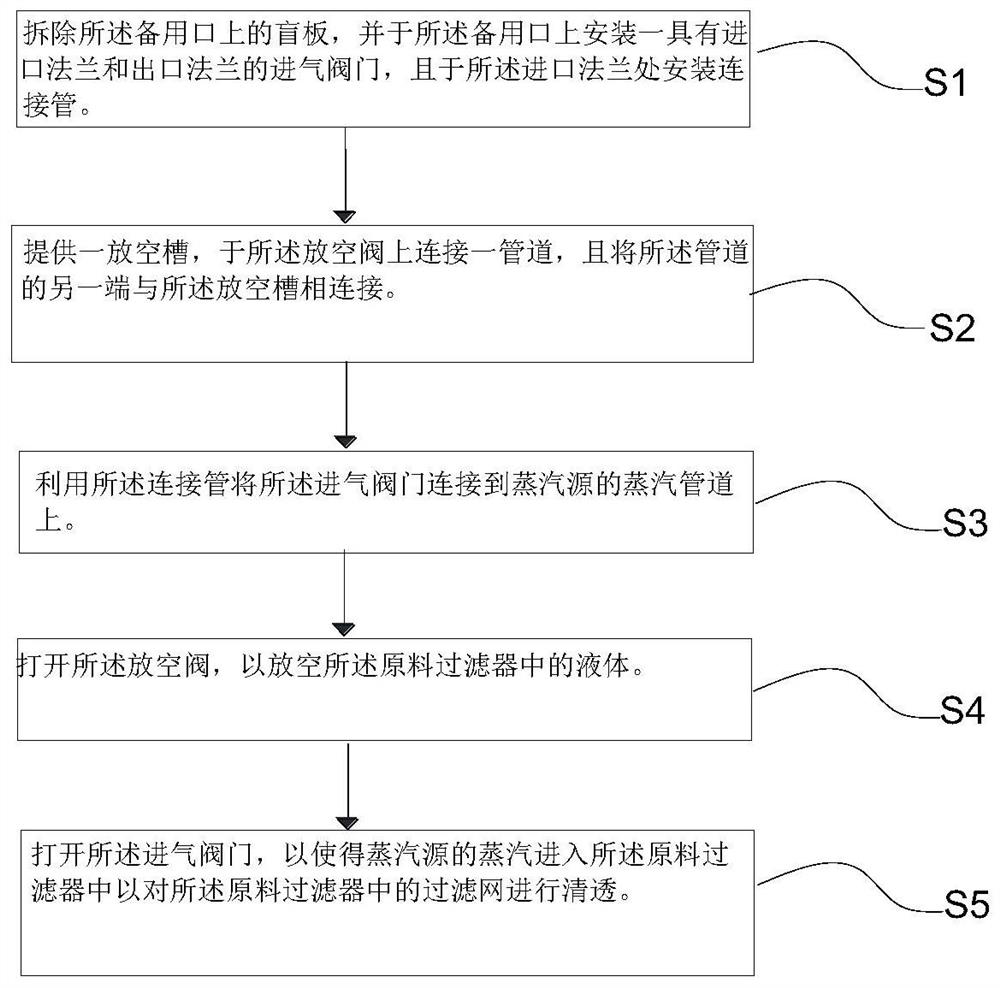

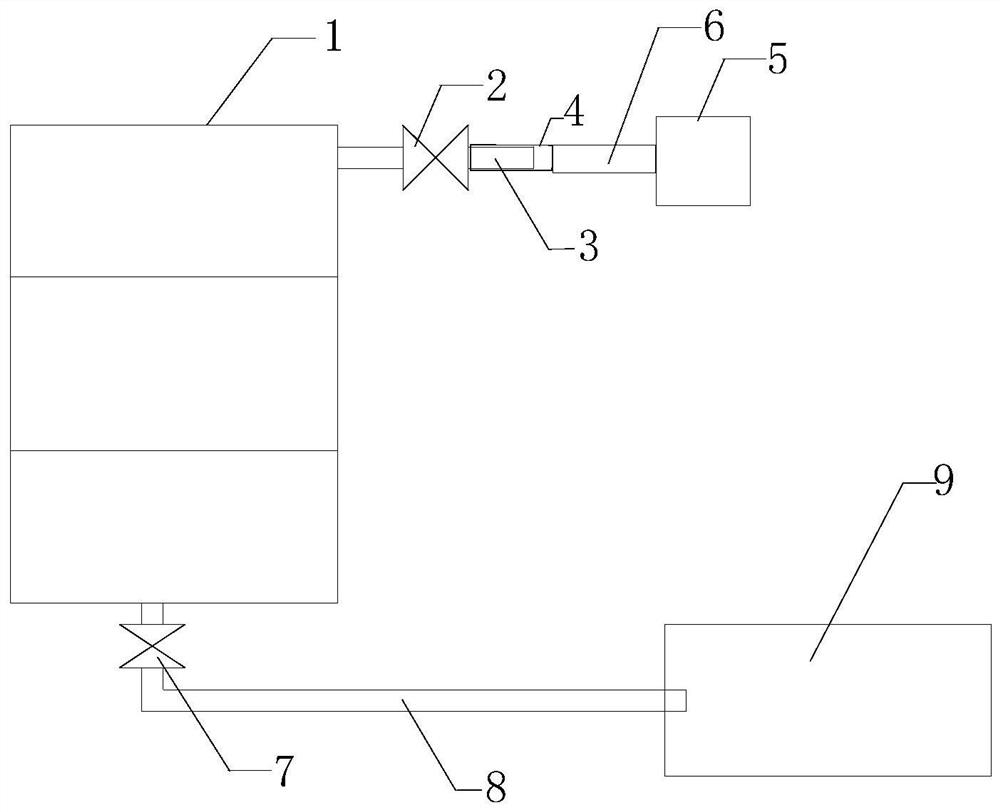

[0024] like figure 1 and 2 As shown, the present invention discloses a method for quickly clearing a raw material filter. The upper part of the raw material filter 1 is provided with a spare port, and the lower part is provided with a vent valve 7; specifically, the method includes the following steps:

[0025] Step S1, remove the blind plate on the spare port, install an inlet valve 2 with an inlet flange and an outlet flange on the spare port, and install a connecting pipe 3 at the inlet flange.

[0026] In a preferred embodiment of the present invention, the connecting pipe 3 is a metal pipe.

[0027] Specifically, the above step S1 includes:

[0028] Step S11, providing a connecting flange, and welding the metal pipe on the connecting flange.

[0029] Step S12, remove the blind plate on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com