Automatic flanging mechanism for steel lining teflon straight pipes

A technology of PTFE-lined straight tubes and automatic turning, applied in the field of chemical equipment, can solve the problems of uneven heating of PTFE tubes, artificial heating of PTFE tubes, and poor quality of flanging, so as to save labor, reduce handling and installation , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

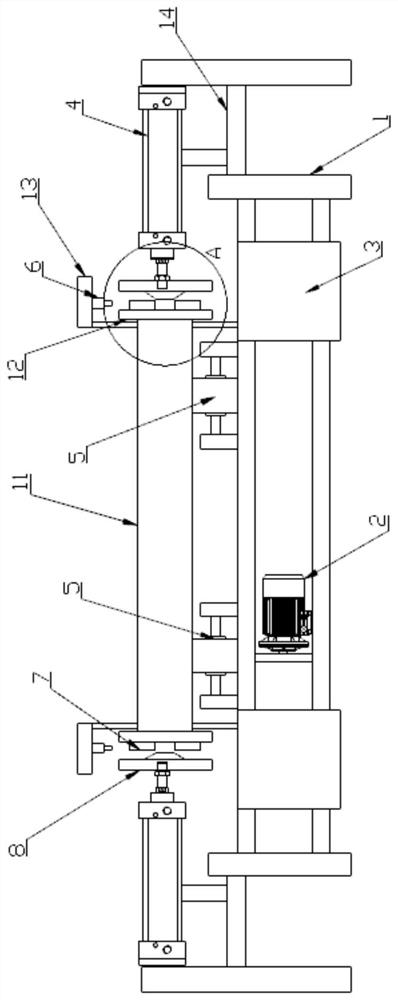

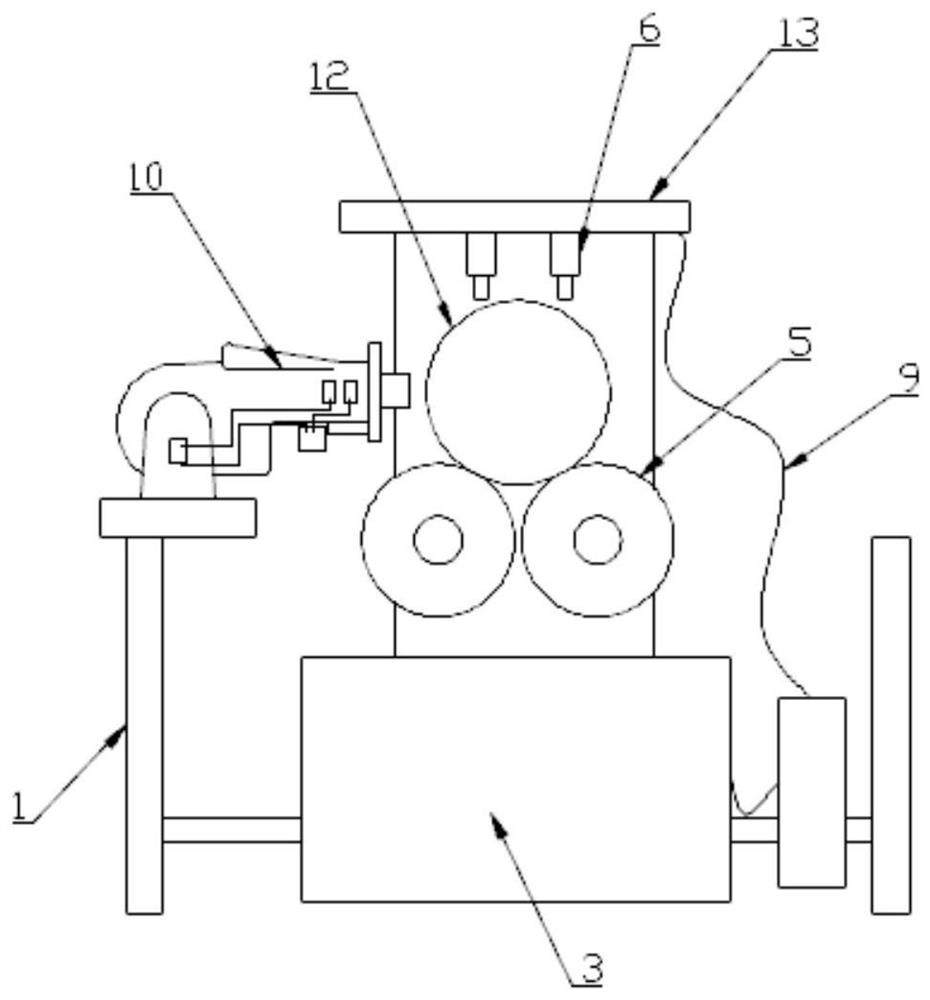

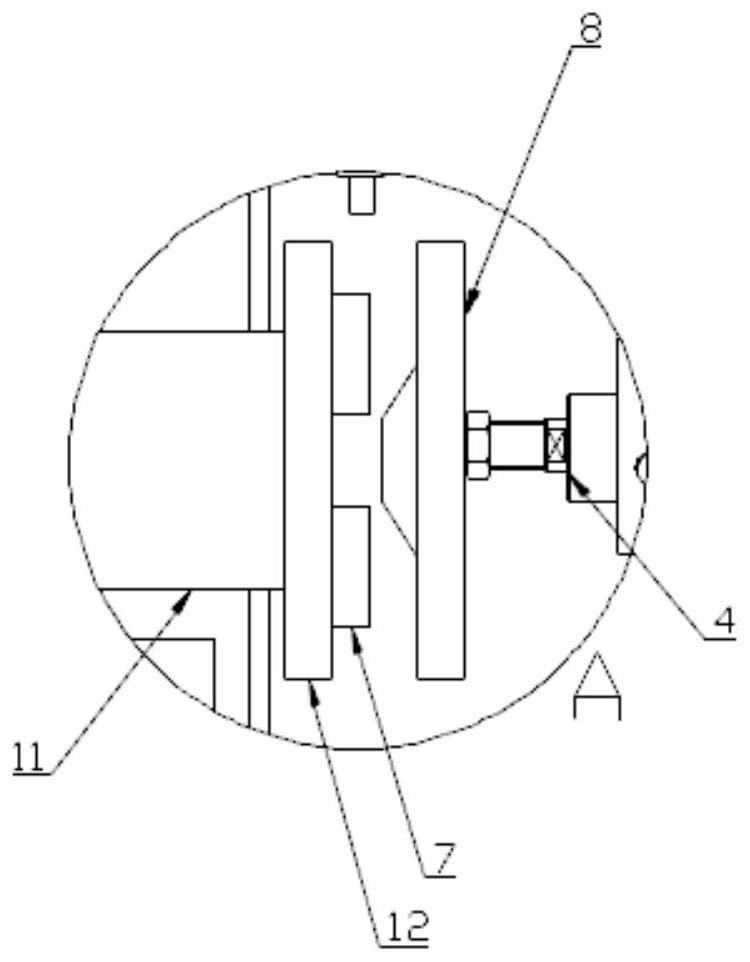

[0026] Such as figure 1 As shown, a steel-lined PTFE straight tube automatic flanging mechanism includes a frame 1, rollers, a burner 10, a top pressure cylinder 4,

[0027] The frame 1 is welded by profiles. A plurality of roller assemblies 5 are installed on the frame 1. The roller assemblies 5 are evenly arranged along the axis of the steel pipe 11. Each roller assembly 5 includes two groups of mandrels, bearings, pedestals, Roller, the roller and the mandrel are connected by bearings, the two ends of the mandrel are installed on the platen, the two rollers are arranged symmetrically, the steel pipe 11 is placed on the two rollers, and the two rollers rotate in the same direction driven by the drive motor 2 to drive the steel pipe 11 spins,

[0028] The bottom of both ends of the frame 1 is provided with a water s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap