An automatic encapsulation machine for capacitor elements

A technology of capacitors and encapsulation machines, which is applied in the manufacture of capacitors, electrical components, capacitors, etc., can solve problems such as low efficiency, waste of manpower and material resources, and achieve the effects of improving work efficiency, high degree of automation, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to automatically complete the production of inner fuses, core encapsulation and inner fuse bonding in the process of manufacturing capacitor elements, the invention provides an automatic encapsulation machine for capacitor elements.

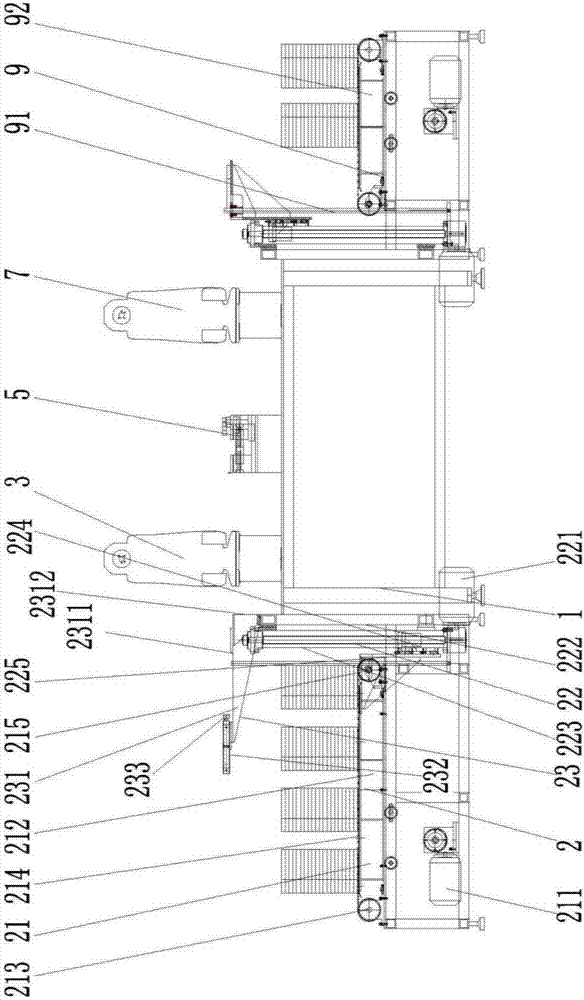

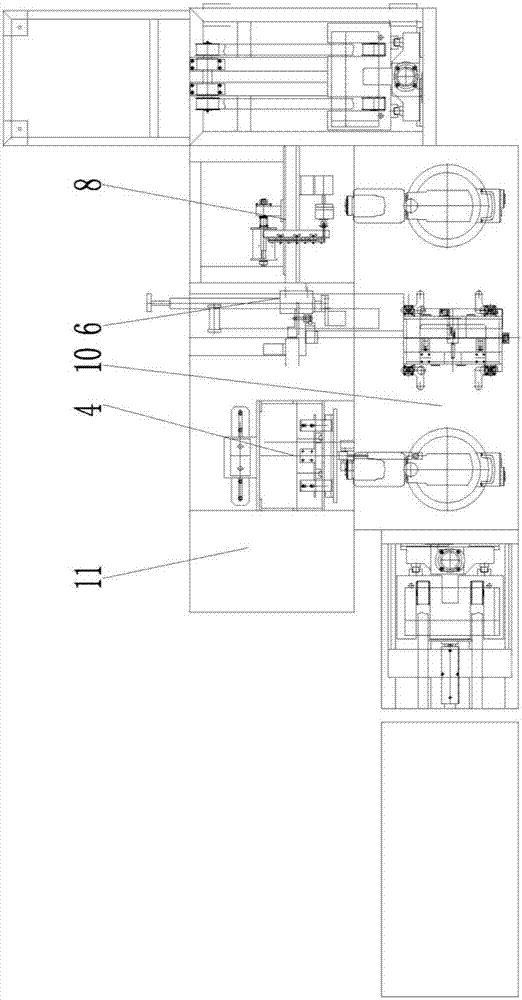

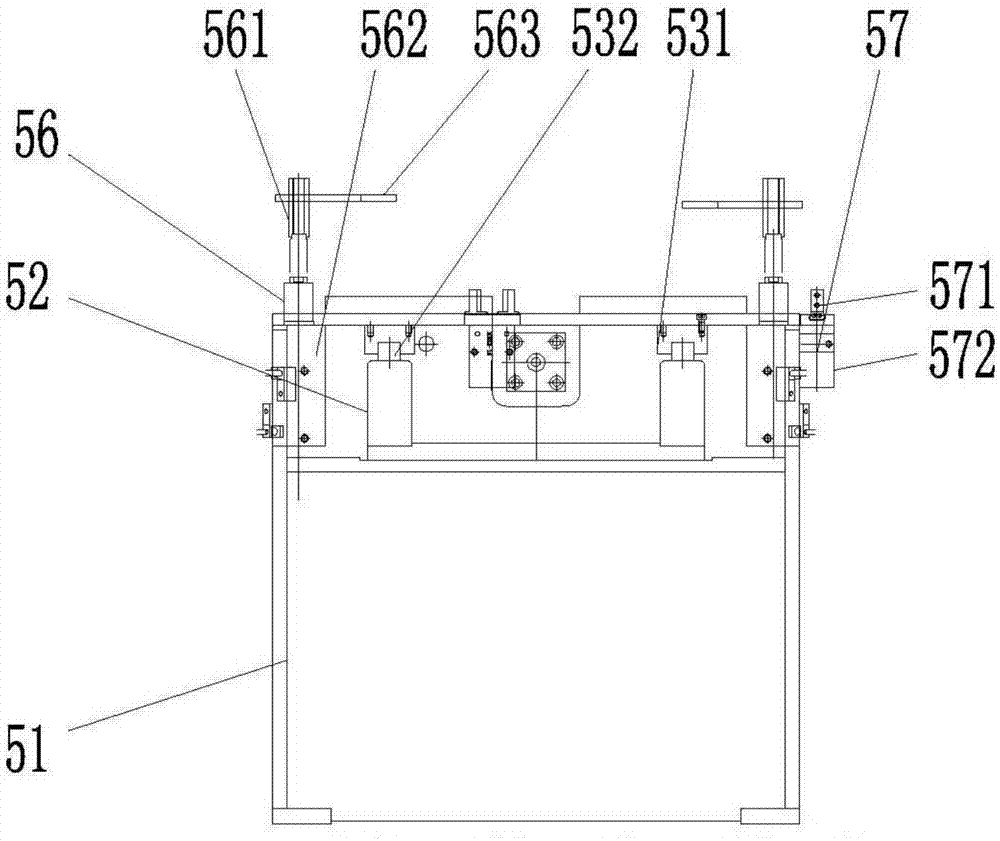

[0048] Such as figure 1 with figure 2 As shown, the overlock sewing machine includes a fixed bracket 1, a feeding mechanism 2, a first manipulator 3, an assembly station 4, an encapsulation station 5, a tape bonding device 6, a second manipulator 7, an inner fuse making machine 8 and a receiving machine. Material mechanism 9;

[0049] The feeding mechanism 2 is installed at the front of the fixed bracket 1 for delivering capacitor core stacks to the working area of the first manipulator 3; the receiving mechanism 9 is installed at the rear of the fixed bracket 1 for wrapping the completed capacitor element Stacking and accumulating; among them, the capacitor cores are piled up one by one.

[0050] The middle part of the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com