A kind of anti-high temperature wet-dry method modified asphalt mixture and its preparation method and application

A technology of modified asphalt and mixture, which is applied to the coagulation pavement, roads, buildings and other directions of on-site paving, can solve the problems of affecting the driving effect and highway performance, poor mechanized construction performance, resistance to rutting and water damage, etc. The effect of reducing maintenance work, improving mechanical construction performance and preventing early damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

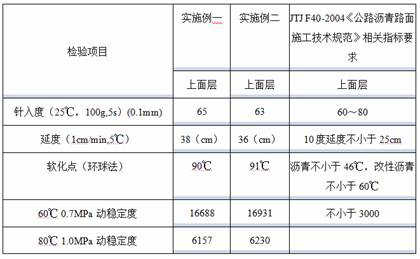

Embodiment 1

[0049] The high temperature resistant wet-dry method modified asphalt mixture of this embodiment includes the following materials in weight percentage:

[0050] Material A: The particle size 16~9.5mm39.953%, 9.5~4.75mm28.537%, 4.75~2.36mm4.756%, 2.36~0mm17.122% crushed stone produced by the Bangalore quarry in Pakistan and the particle size is less than 0.6 mm mineral powder 4.756% total 95.124%;

[0051] Material B: 4.2% of 60-70 bitumen produced in Pakistan;

[0052] Material C: SBS 0.165%;

[0053] Material D: rubber oil 0.070%;

[0054] Material E: stabilizer (petroleum resin + sulfur, the ratio is 1:0.72) 0.011%;

[0055] Material G: rock asphalt + diatomaceous earth 0.430%. Rock asphalt + diatomaceous earth, rock asphalt: diatomaceous earth by weight ratio = 1:1.

[0056] The preparation method of the high temperature resistant wet-dry method modified asphalt mixture of the present embodiment comprises the following steps:

[0057] Step (1), heating the 60-70 asphalt...

Embodiment 2

[0073] The high temperature resistant wet-dry method modified asphalt mixture of this embodiment includes the following materials in weight percentage:

[0074] Material A: The particle size 16~9.5mm40.463%, 9.5~4.75mm27.609%, 4.75~2.36mm6.188%, 2.36~0mm18.089% crushed stone produced by Pakistan Bangalore quarry and the particle size is less than 0.6 mm mineral powder 2.856% total 95.205%;

[0075] Material B: 4.1% of 60-70 bitumen produced in Pakistan;

[0076] Material C: SBS 0.155%;

[0077] Material D: rubber oil 0.080%;

[0078] Material E: stabilizer (petroleum resin + sulfur, the ratio is 1:0.72) 0.010%;

[0079] Material G: rock asphalt + diatomaceous earth 0.450%. Rock bitumen + diatomaceous earth, rock bitumen: diatomite by weight ratio = 1:0.8.

[0080] The preparation method of the high temperature resistant wet-dry method modified asphalt mixture of the present embodiment comprises the following steps:

[0081] Step (1), heating the 60-70 asphalt produced in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com