Automatic tiling machine

A kind of brick machine and automatic technology, which is applied in the direction of construction and building construction, etc., can solve the problems that cannot be popularized and used, has no solution, and has a single function, and achieves the effect of simple and reliable horizontal and vertical calibration, improved efficiency, and complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

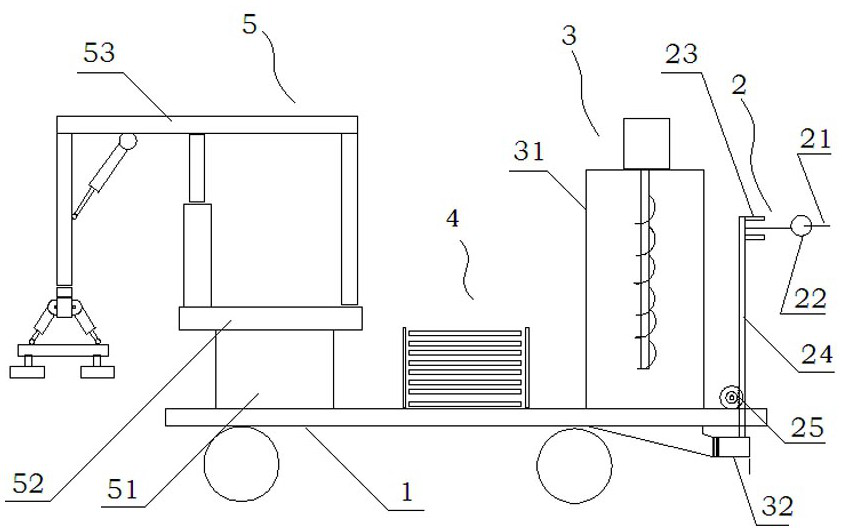

[0020] Such as figure 1 As shown, an automatic tile laying machine includes a platform 1 with a walking mechanism, on which a horizontal correction mechanism 2, a stirring and unloading mechanism 3, a brick tank 4 and a brick laying rocker mechanism 5 are successively installed, and the stirring The unloading mechanism 3 includes a material barrel 31 and a discharge pipe 32 that is softly connected to the discharge port at the bottom of the material barrel. The horizontal control unit is connected to the discharge pipe 32 ; the tile laying rocker mechanism 5 includes a base 51 and a rocker assembly 53 connected to the base 51 through a rotating disc 52 .

[0021] When laying floor tiles, after the binder (mixed with cement, yellow sand, etc.) is evenly stirred in the stirring and discharging mechanism, the walking mechanism drives the platform to walk, and the stirring and discharging mechanism discharges the material through the discharge pipe. At this time, the horizontal co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com