Plunger pump fluid end

A liquid end and plunger pump technology, applied in the field of plunger pump liquid end, can solve problems such as valve box cracking, valve box sealing surface wear, personal safety and operating efficiency, etc., to reduce stress and improve use Long life, simple and fast installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

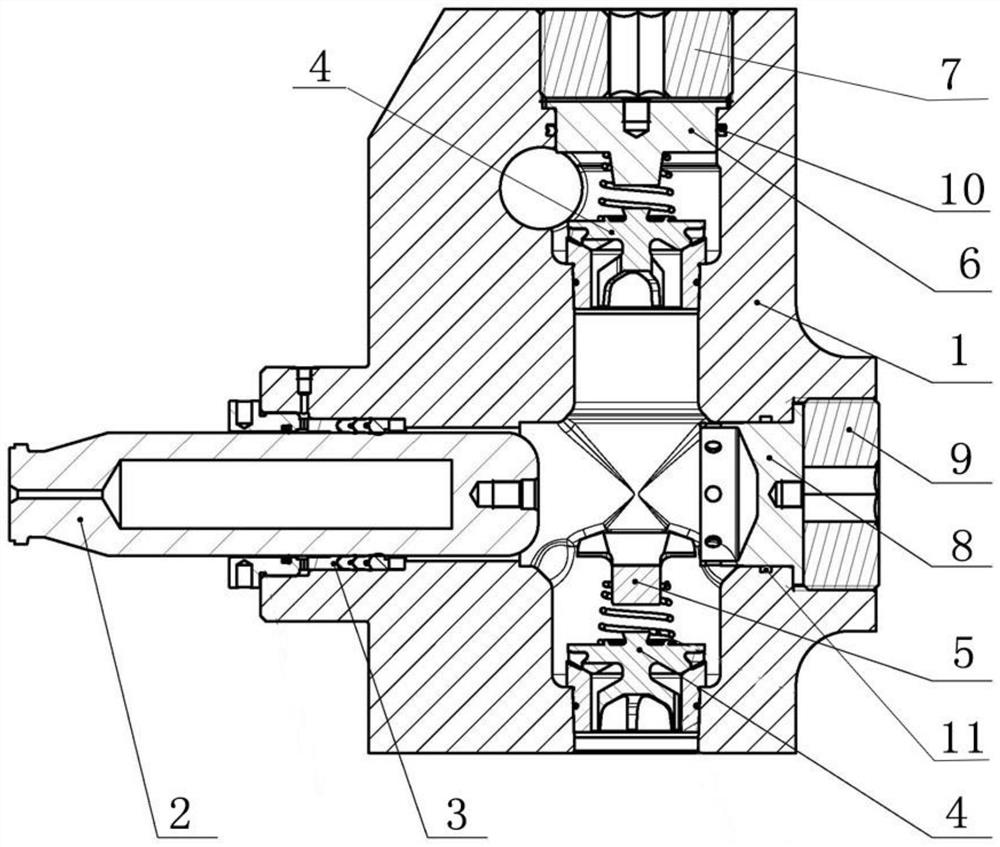

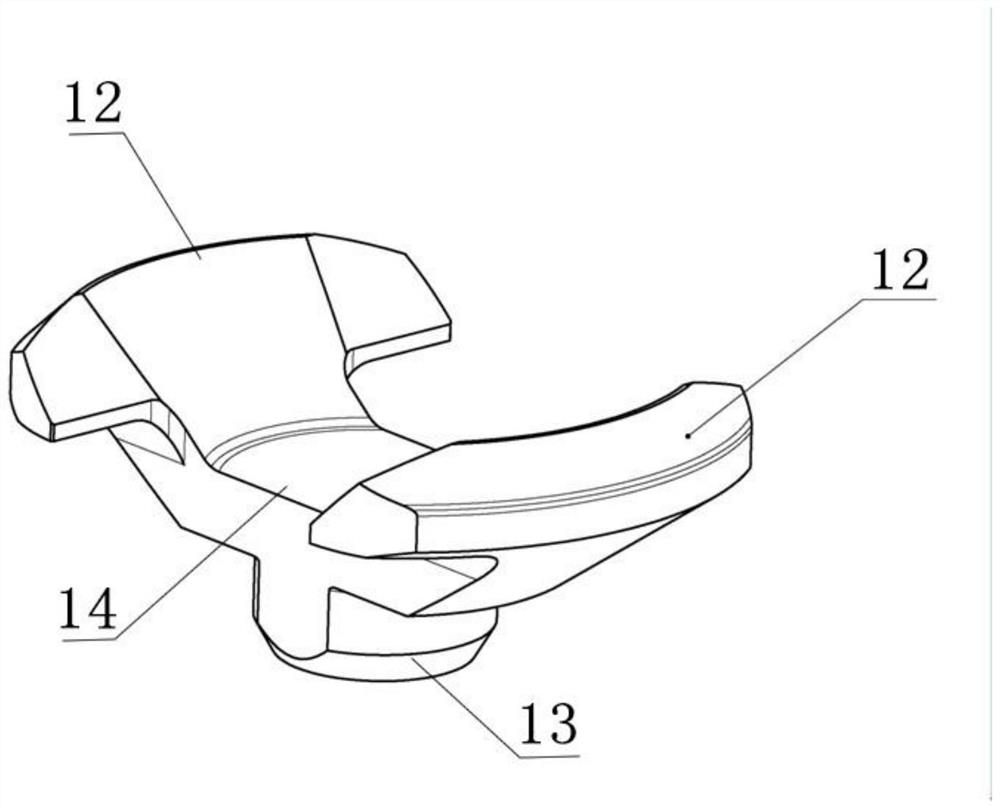

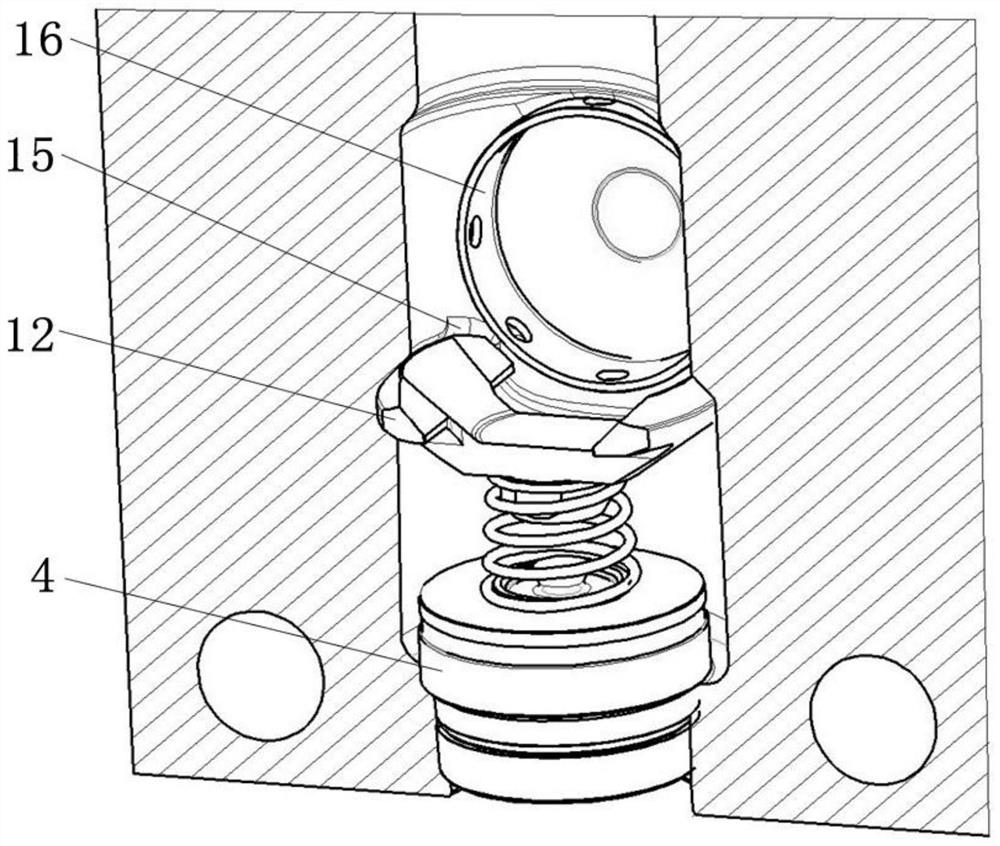

[0022] Such as Figures 1 to 4 As shown, a hydraulic end of a plunger pump includes a valve box 1, a plunger 2, a packing seal assembly 3, a valve assembly 4, a valve spring seat 5, a discharge gland 6, a discharge gland 7, The suction gland 8 and the suction gland 9 are provided with a suction cavity and a discharge cavity in the vertical direction inside the valve box 1, and a packing cavity and a suction gland 8 cavity in the horizontal direction inside the valve box 1. The valve assembly 4 and the valve spring seat 5 are set in the middle, and the valve assembly 4 and the valve spring seat 5 are connected. In the discharge cavity, the valve assembly 4, the discharge gland 6 and the discharge pressure cap are arranged in sequence from the inside to the outside. 7. The valve assembly 4 is connected with the discharge gland 6, and the discharge gland 7 is used to compress the discharge gland 6. In the packing cavity, the plunger 2 is sealed and connected with the valve box 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com